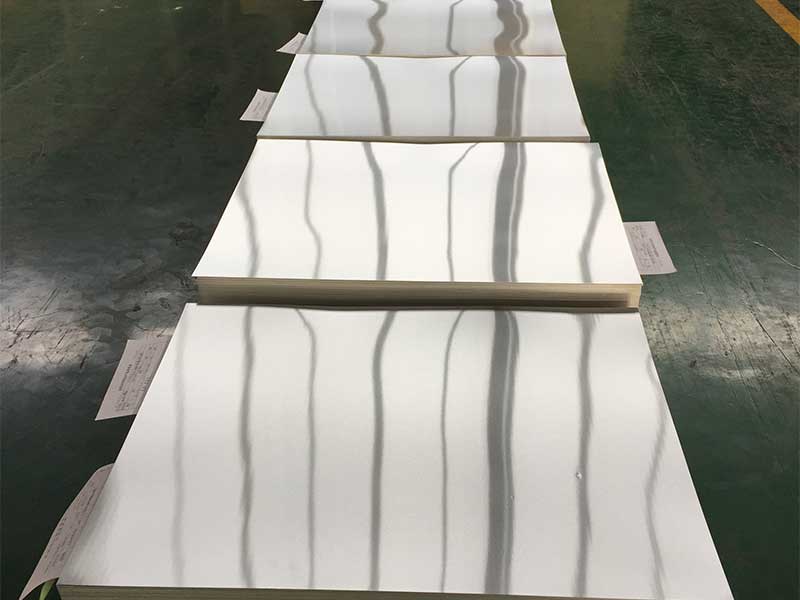

Plain Aluminium Sheet Metal 1100 3003 1050 1060 8011 5052

When we think about materials that shape our daily lives, aluminum often flits under the radar next to the showier metals like steel, but this versatile little giant packs a punch with functionality and performance. Among the various forms of aluminum, the plain aluminum sheet metals—especially grades 1100, 3003, 1050, 1060, 8011, and 5052—are champions of an unsung production revolution happening all around us.

The Basics: Knowing Your Aluminum Grades

First things first, what is it that distinguishes these numbers and letters? Each grade corresponds to a specific blend of alloys which delivers unique characteristics perfect for various tasks.

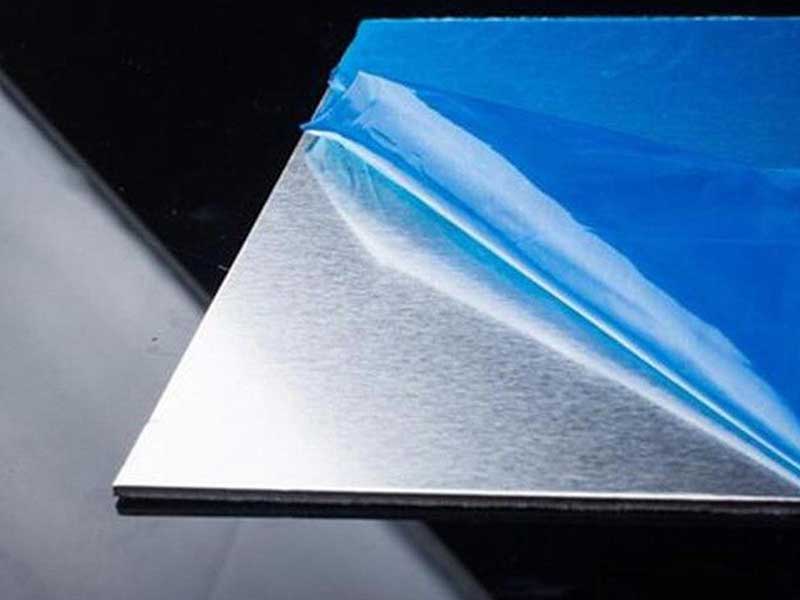

Working with 1100, 3003, 1050, 1060, 8011, and 5052 aluminum sheet alloys daily, I've noticed distinct personality traits in each. The 1100, our workhorse, is incredibly ductile and easy to form – a joy to work with for simple processes. However, it's comparatively soft, demanding extra care during handling to avoid scratching or denting. The 3003, a slightly stronger alloy with good workability, is our go-to for applications needing a bit more structural integrity, like thicker components. Conversely, the 1050 and 1060 series are surprisingly similar in behavior, though 1060 shows slightly improved strength, both excel in applications demanding high reflectivity. Their soft nature makes them a bit more challenging to handle on the automated lines compared to the 3003.

Then there are the 8011 and 5052. 8011, with its superior formability, is perfect for deep drawing operations, producing beautiful, seamless parts. However, its softness requires meticulous attention to prevent deformation during the manufacturing stages. 5052, our workhorse for corrosion resistance, is notably tougher than the others. While demanding more tooling horsepower during forming, its durability and resistance to atmospheric elements makes it invaluable for

-

1100: This is pure aluminum (99%+) with excellent corrosion resistance and good workability. It’s often found in food processing, chemical handling, and heat exchangers. If lightness and classic durability were in a beauty pageant, 1100 would take home the crown.

-

3003: This blend adds a little punch, containing manganese that enhances strength while keeping it easy to work with. It’s a favorite choice for making custom aluminum cooking utensils and dorm fridge cabinets. As far as good looks go, you’ll spot it on cookware or cigarette cases without breaking a sweat.

-

1050 & 1060: Both are purity aluminum grades (with greater than 99% aluminum content). They bring excellent elongation and solderability which are simply irresistible for manufacturers looking at application specific pressures and thermal stability. You regularly walk past them as they make various components for electrical applications and reflective surfaces.

-

8011: Commercially used for products needing fatigue resistance, it is common in beverage and pharmaceutical packaging. It’s lightweight yet solid enough to be a handle on flexing fitness gear. Catch them in your favorite beer can or take-out food containers!

-

5052: This offering springs from adding magnesium to the mix, yielding extraordinary corrosion resistance and forming abilities. Renowned as a go-to sheet for marine applications, you'll often find it on boats and other salty companions who need protection against corrosive waters.

Functions & Applications - They Can Do It All!

Far from being a one-trick pony, the diversity among aluminum grades embodies their incredible adaptability to practically any meaning of craftsmanship or industrial effort. Depending on the quality and characteristics, aluminum sheets can quickly turn into roofs for both Mercedez-Benz’s luxurious ride and sturdy refrigerated trucks skidding along icy highway turns.

-

Automotive: The lightweight nature of aluminum allows manufacturers to produce vehicles that are both fuel-efficient and robust.

-

Aerospace and Aviation: These sheets adjust well to corroding environments found up here where the ducks fly high without flapping wings, which makes aluminum grades uniquely beneficial for creating durable fuselage skins and internal structural components.

-

Construction and Architecture: Critics may not believe their eyes as beams of confident aluminum—which often unexpectedly harmonize rooftops, facades, and safety rails—support beautifully designed buildings both on aesthetics and sense of duty.

-

Electronics and Electrical: Reliability wins the day! For electrical applications, aluminum sheets help build shared parts, enhancing ductility and conductivity. Grade-grade reflects lower operational temperatures in your electronic gadgets which is like singing Karaoke with an audience politely watching.

Wrapping Up Through The Looking Glass

The world of plain aluminum sheets is vibrant and ornate, quietly whispering the multitude of functions and design possibilities when spotlighted in architecture, manufacturing, and local crafts. As customers, it’s vital not only to track these exquisite versatile materials but understand why you’d want to choose the right grade that fits your intentions.

Each grade of aluminum provides a signature flavor—some smooth (1100), while others have delicate notes of strength and resiliency (5052)—demonstrating that whether it spins, shapes, or supports, metallurgy knows: being light and economical can also mean superb performance and durability.

So the next time you breach that aluminum seam on the can of your soda or toss a sheet of these lovely metals into a building project, you might just find yourself and appreciating those unassuming traits bubbling beneath the surface. Quick tip: appreciation is free, and you can turn an empty can into an unbottled tale! Cheers to aluminum, huh?

https://www.al-alloy.com/a/plain-aluminium-sheet-metal-1100-3003-1050-1060-8011-5052.html