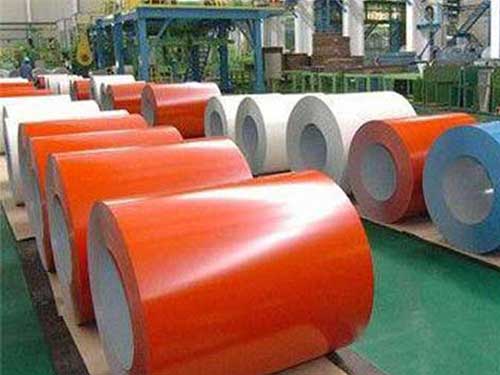

Color flat aluminum coils

Color Flat Aluminum Coils: The Unsung Hero of Modern Design and Durability

In the realm of architectural materials and industrial applications, color flat aluminum coils is know as a versatile and highly functional component that often flies under the radar. While many focus on aluminum’s durable, lightweight nature, the transformative role played by the coloration and flat-coil form factor deserves close attention.

What Are Color Flat Aluminum Coils?

At their core, color flat aluminum coils are aluminum sheets rolled into coils, processed to achieve a perfectly smooth and flat surface, and then coated with a variety of colors using advanced techniques such as PVDF (polyvinylidene fluoride) or polyester coatings. This combination of shape, finish, and durable coloration transforms raw aluminum into a customizable material ready for countless applications.

Why Color Matters: Beyond Surface Beauty

Color flat aluminum coils are not just about appearance. While the vibrant hues and sleek finishes offer architects and designers an exceptional visual palette, coloration serves multiple functional roles too:

- Protection Against Elements: Coatings provide a protective barrier against corrosion, UV rays, and even chemical pollutants, thereby extending the lifespan of the aluminum.

- Heat Reflectivity and Management: Choosing lighter or reflective colors can reduce heat absorption in buildings, contributing to better energy efficiency, especially in warmer climates.

- Brand Differentiation: For manufacturers of consumer goods or signage, customized colors can be integral to brand identity, making the product immediately recognizable.

The Flat Coil Advantage: Flexibility and Uniformity

The “flat coil” form factor is practical and efficient. Unlike large, unwieldy sheets, coils facilitate continuous processing which allows for:

- Seamless Fabrication: Factories can unroll, cut, and process exactly the length required, minimizing waste.

- Consistent Thickness and Surface: Flat coils are produced under stringent controls, ensuring uniformity critical for high-precision applications like electronics housings, roofing panels, and automotive parts.

- Ease of Transportation and Storage: Coiling sheets drastically reduces the footprint and damage risk during handling and distribution.

Distinct Applications Enhanced by Color Flat Aluminum Coils

- Architecture & Construction: Modern façades, ceilings, and curtain walls employ color flat aluminum coils for their balance between strength, aesthetics, and weather resistance.

- Appliances: The sleek finish and corrosion resistance provide appliance manufacturers a durable branding tool that doesn’t sacrifice style.

- Transportation: Lightweight color-coated aluminum panels help reduce vehicle weight while maintaining durability and allow versatile design options from buses to planes.

- Signage and Advertising: Vibrant, steady coils make creating large displays and signs more straightforward and appealing.

Sustainability and Recyclability

Aluminum’s well-known recyclability pairs nicely with color flat aluminum coils. The coatings used today are engineered to be eco-friendly and durable enough to extend product life, reducing replacement frequency and waste. By choosing coated aluminum coils, industries can align their goals with sustainability—less material use, longer product lifecycles, and better recyclability.