1.0mm 2.0mm 1050 1060 1070 1100 Aluminum Sheet

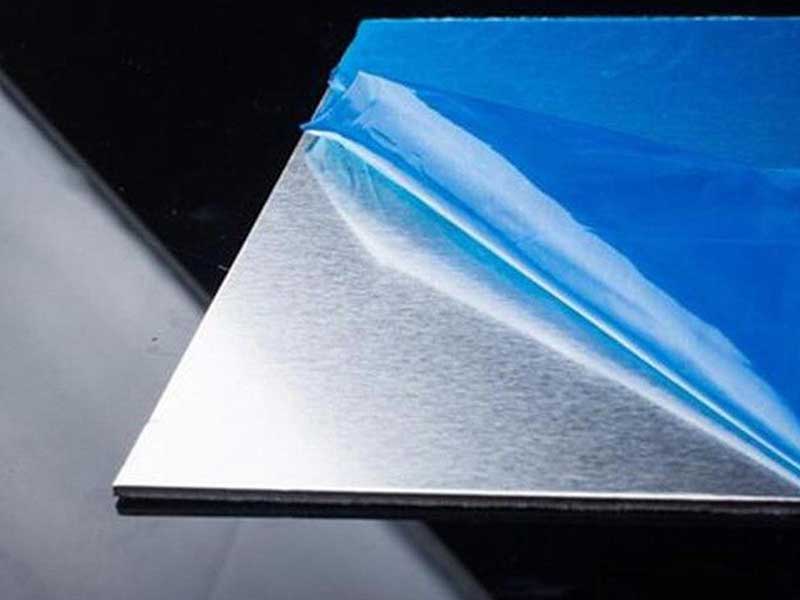

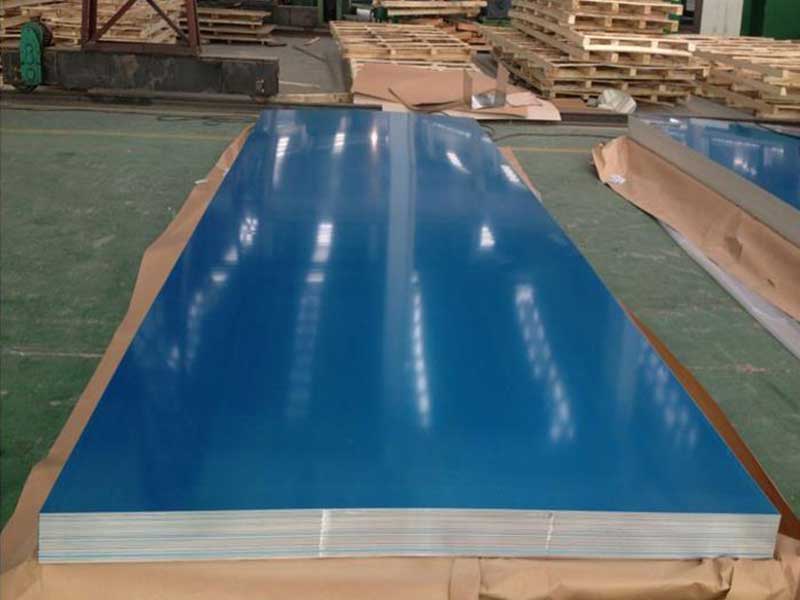

Aluminum sheets play a pivotal role in numerous applications across various industries, thanks to their incredible versatility, lightweight nature, and excellent corrosion resistance. Among the array of aluminum alloys available, the 1.0mm and 2.0mm sheets in 1050, 1060, 1070, and 1100 grades is know as particularly popular choices.

Understanding Aluminum Alloys: 1050, 1060, 1070, and 1100

1050 Aluminum Sheet

1050 aluminum alloy is known for its outstanding corrosion resistance and excellent workability. With a purity level of 99.5% aluminum, 1050 sheets are suitable for applications requiring high conductivity, like electrical and chemical environments. The 1.0mm and 2.0mm sheets in this grade provide adequate strength while remaining lightweight, making them ideal for applications in electrical wiring and high-requirement decorative purposes.

1060 Aluminum Sheet

Similar to 1050, 1060 aluminum sheet contains a higher aluminum content (99.6% purity), further enhancing its properties. The 1.0mm and 2.0mm options are perfect for industries needing materials that combine lightweight attributes with high thermal and electrical conductivity. Applications include cooking utensils, storage tanks, and heat exchangers, where reliability and performance are non-negotiable.

1070 Aluminum Sheet

With an even higher purity than the previous options, the 1070 aluminum alloy boasts a minimum purity of 99.7%. This translates to excellent corrosion resistance and workability. The 1.0mm and 2.0mm sheets in the 1070 grade are highly sought after for aerospace and electronics industries, where exceptional performance and reliability are critical. They are also widely used in architectural applications where aesthetics are as crucial as functionality.

1100 Aluminum Sheet

The 1100 aluminum alloy is another great option that features a mix of aluminum (99.0% minimum) with small amounts of other elements, enhancing its formability and weldability. The versatile 1.0mm and 2.0mm sheets made from 1100 aluminum are excellent for pressure vessels, food processing, and chemical handling. This makes them popular in the manufacturing and fabrication industries, often used for refrigerator panels and heat exchangers.

Comparing 1.0mm and 2.0mm Aluminum Sheets

Choosing between 1.0mm and 2.0mm aluminum sheets largely depends on the specific requirements of your application. The 1.0mm sheets provide an advantage in applications where weight is a priority yet some degree of strength is necessary. Conversely, 2.0mm sheets are favored for their enhanced strength and rigidity, coping better with demanding environments.

Advantages of 1.0mm and 2.0mm Aluminum Sheets

- Lightweight: Both thicknesses offer reduced weight compared to alternative materials like steel, promoting efficiency in transport and installation.

- Corrosion Resistant: Each aluminum alloy exhibits great resistance to weather and various chemicals, making them long-lasting options.

- Ease of Fabrication: They can be easily cut, shaped, and joined, making them suitable for a variety of applications.

- Recyclable: Aluminum's recyclability lowers the ecological footprint, making these sheets an environmentally friendly material choice.

https://www.al-alloy.com/a/10mm-20mm-1050-1060-1070-1100-aluminum-sheet.html