1050 1060 h14 h22 decking aluminum alloy sheets

When it comes to choosing materials for construction projects, aluminum alloys are often highlighted for their excellent properties such as lightweight, corrosion resistance, and versatility. Among these alloys, 1050 and 1060 H14 and H22 decking aluminum sheets have gained considerable attention due to their unique characteristics and numerous applications. In this article, we'll delve into these specific aluminum alloys, explore their properties, and understand their optimal uses in decking applications.

Understanding Aluminum Alloys 1050 and 1060

1. 1050 Aluminum Alloy

1050 aluminum alloy is well-known for its excellent thermal and electrical conductivity. With a purity level of 99.5% aluminum, it possesses remarkable plasticity and is easy to work with. In the H14 temper, the material undergoes strain hardening, granting it enhanced strength compared to its annealed state while retaining sufficient ductility. This makes 1050 H14 aluminum sheets a preferred choice for applications requiring good corrosion resistance and formability.

2. 1060 Aluminum Alloy

Similar to the 1050 alloy, 1060 aluminum boasts a high purity level (at least 99.6% aluminum). It is commonly used in various industrial applications and shares similar properties with the 1050 alloy, albeit with slightly higher strength. The H14 and H22 tempers make 1060 aluminum sheets ideal for applications that involve moderate strength requirements alongside excellent workability. The H22 temper provides a thicker finish that offers added durability, making it suitable for structural applications.

Key Properties of H14 and H22 Tempered Aluminum Sheets

Strength and Durability

H14 and H22 tempering processes enhance the strength of aluminum sheets, making them more suitable for demanding applications. H14 indicates a moderately hard condition where the alloy exhibits enhanced yield strength, while H22 provides greater rigidity and resistance to deformation.

Lightweight

One of the main advantages of using aluminum alloy sheets, including 1050 and 1060, is their lightweight nature. This feature significantly reduces the overall weight of decking and other structural elements, making transportation and installation much simpler and more cost-effective.

Corrosion Resistance

Both aluminum alloys have excellent resistance to corrosion, allowing them to withstand various environmental conditions. This makes them especially suitable for outdoor applications such as decorative decking, patios, and other exterior structures.

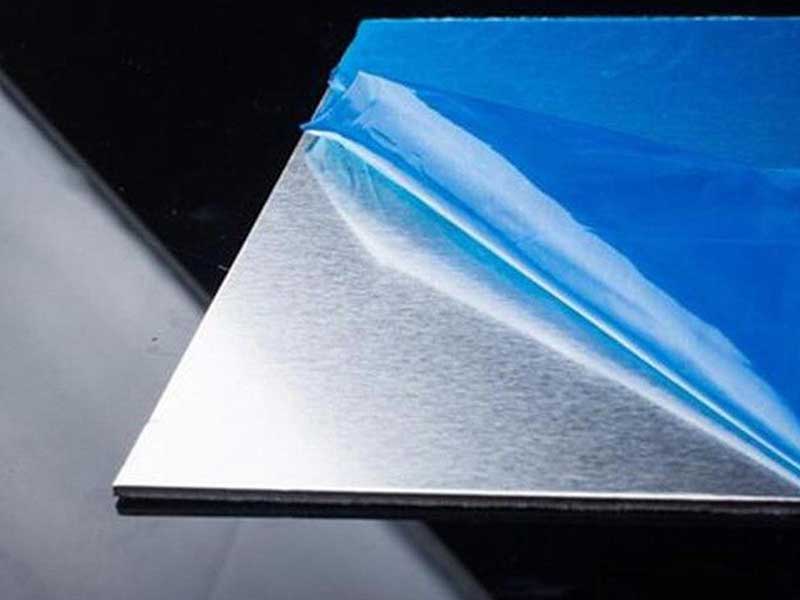

Formability

The formability of 1050 and 1060 H14 and H22 sheets allows for easy manipulation and shaping into different configurations. They can be easily cut, welded, and bent, catering to varied design requirements while maintaining structural integrity.

Applications of 1050 and 1060 H14 H22 Decking Aluminum Alloy Sheets

Due to their superior properties, 1050 and 1060 aluminum sheets find applications in diverse industries. Here are some common uses:

-

Decking: These aluminum sheets are ideal for outdoor decking applications due to their lightweight, durable, and corrosion-resistant characteristics. They can withstand the elements while remaining aesthetically appealing.

-

Facade Cladding: The smooth finish of 1050 and 1060 alloys lend themselves well to exterior architectural designs, providing a sleek appearance and the added benefit of high-strength and low-weight properties for builders.

-

Industrial Applications: Both alloys are employed in manufacturing various industrial components, including heat exchangers, storage tanks, and electrical enclosures, making them versatile in production.

-

Transportation: The lightweight nature of aluminum sheets makes them perfect for vehicle panels, trailers, and various parts of transport equipment, contributing to overall fuel efficiency.

https://www.al-alloy.com/a/1050-1060-h14-h22-decking-aluminum-alloy-sheets.html