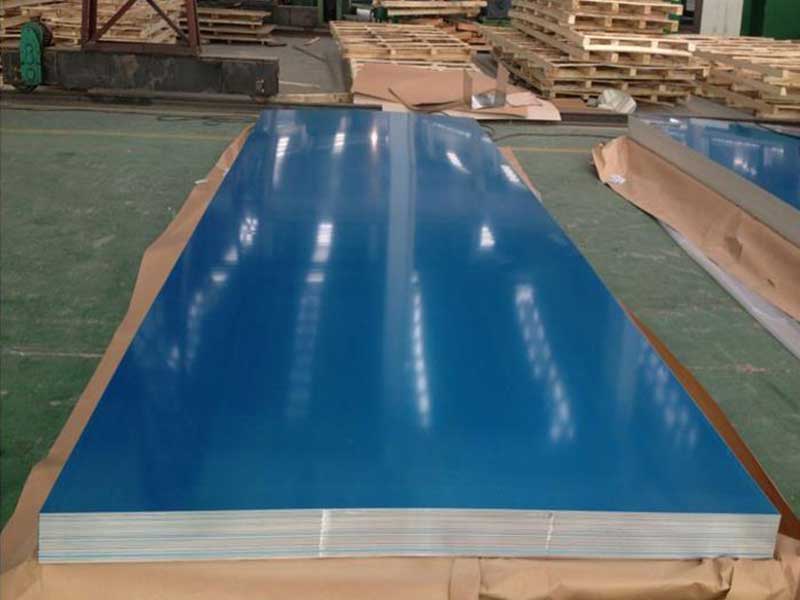

Aluminum sheet 1050 material

Aluminum sheet 1050 is one of the most popular choices in the aluminum alloys segment, prized for its remarkable characteristics and wide-ranging applications. With its unique properties, aluminum sheet 1050 material is extensively utilized across various industries, making it an essential component in metalworking and construction. This article explores the defining traits and benefits of aluminum sheet 1050, as well as its diverse uses.

What is Aluminum Sheet 1050?

Aluminum sheet 1050 belongs to the 1000 series of aluminum alloys, which are primarily composed of 99% or higher aluminum content. This high purity level not only enhances its desirability but also offers excellent workability and aesthetic appeal. Known for its exceptional corrosion resistance and remarkable thermal conductivity, aluminum sheet 1050 is an ideal choice for diverse commercial and industrial applications.

Properties of Aluminum Sheet 1050

Understanding the properties of aluminum sheet 1050 material helps clarify why it's a favored choice in many sectors. Some key characteristics include:

-

High Corrosion Resistance: Aluminum inherently demonstrates a strong resistance to corrosion. The oxide layer that forms over time reinforces the material's durability, making aluminum sheet 1050 suitable for harsh conditions.

-

Good Electrical Conductivity: Aluminum sheet 1050 offers excellent electrical conductivity, making it an appealing option for electrical applications, such as bus bars and electrical enclosures.

-

Malleability and Formability: One of the significant advantages of aluminum sheet 1050 is its malleable nature, which allows it to be easily formed into complex shapes. This quality is crucial for industries that require precise fabrication and unique designs.

-

Lightweight: Compared to other metals, aluminum is notably lightweight, which allows for reduced transportation costs and easy installation in various applications.

-

Recyclability: Aluminum is an eco-friendly material, as it can be recycled without compromising its properties. This feature resonates with environmentally conscious industries and companies promoting sustainability.

Applications of Aluminum Sheet 1050

The unique properties of aluminum sheet 1050 material open up numerous practical applications across various industries:

-

Food and Beverage Industry: Due to its corrosion resistance and hygiene-friendly nature, aluminum sheet 1050 is often used in food processing and packaging.

-

Construction: Widely employed in building facades, roofing, and structural components, aluminum sheet 1050 is favored for its lightweight property, minimizing material costs while enhancing design flexibility.

-

Electrical Manufacturing: Aluminum sheet 1050's excellent electrical conductivity makes it ideal for fabricating wires, connectors, and various electrical panels.

-

Automotive and Transport: The lightweight characteristics and robust structural integrity facilitate its application in vehicle body panels and other automotive parts, improving fuel efficiency without compromising safety.

-

Signage and Displays: Thanks to its aesthetic attribute, aluminum sheet 1050 is used for creating eye-catching signs and displays, ensuring they’re both functional and visually striking.

https://www.al-alloy.com/a/aluminum-sheet-1050-material.html