Grade 3003 H24 Aluminum Foil

Grade 3003 H24 Aluminum Foil: The Unsung Hero of Everyday Durability and Versatility

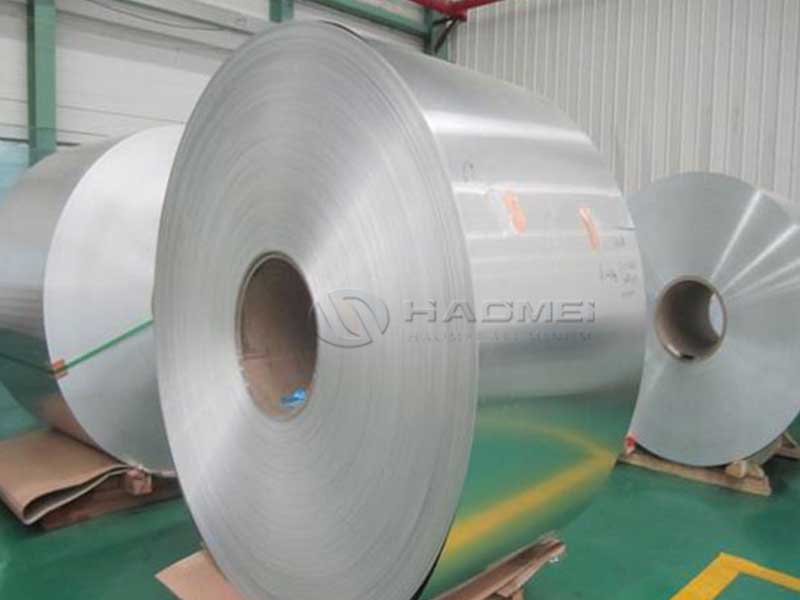

In the world of metals, aluminum often takes center stage for its lightweight and corrosion-resistant properties. Among the many alloys, Grade 3003 H24 aluminum foil holds a unique position, blending distinguished characteristics that make it indispensable across a variety of industries.

What Makes Grade 3003 H24 Aluminum Foil Special?

At its core, Grade 3003 aluminum alloy consists primarily of pure aluminum with around 1.2% manganese. This addition is no minor detail — manganese enhances strength considerably compared to pure aluminum (like Grade 1100) without sacrificing excellent corrosion resistance. The H24 temper means the foil is strain-hardened and partially annealed, striking a superb balance of moderate hardness, strength, and flexibility.

- Durability and Flexibility: Unlike fully soft or fully hardened foil versions, H24 temper offers optimum pliability with enough reinforcement to withstand tears and punctures during handling or packaging.

- Corrosion Resistance: Thanks to the manganese content and natural oxide layer, 3003 H24 foil resists chemical attacks from moisture and many organic acids, making it suitable for food packaging and outdoor usage.

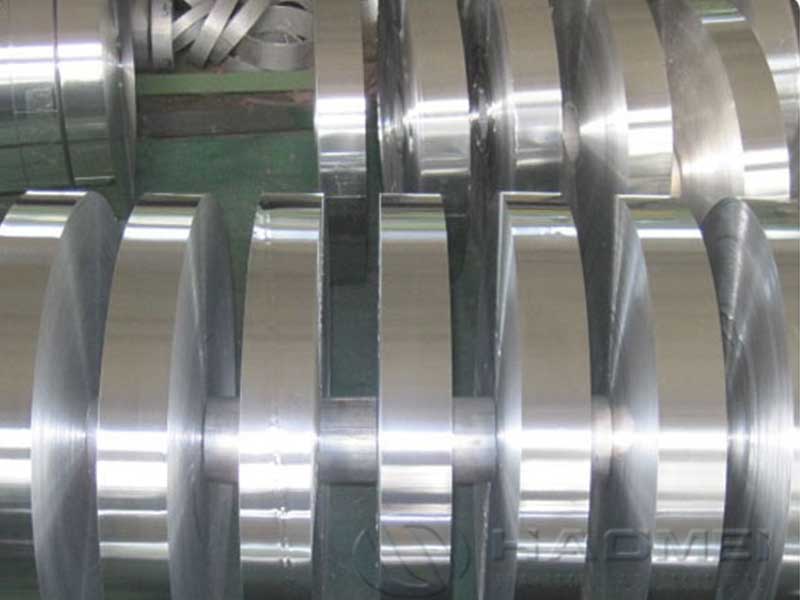

- Good Workability: Even with its enhanced strength, this grade’s excellent ductility enables it to be rolled into ultra-thin sheets without cracking, ideal for applications requiring precise thickness control.

- Thermal Conductivity: Although not the highest among aluminum grades, it provides adequate heat conduction, useful for heat dissipation in certain insulation and cooking-related uses.

Distinct Applications Reflecting Grade 3003 H24 Foil’s Strength and Adaptability

The unique intersection of mechanical strength, corrosion resistance, and formability opens doors to diverse usage across multiple sectors:

-

Food Packaging and Wrapping: The everyday convenience of food foils in kitchens worldwide often traces back to 3003 H24 aluminum. Its resilience against oils, acids from food, and moisture makes it an excellent barrier that preserves freshness while protecting food from contamination.

-

Medical and Pharmaceutical Packaging: In circumstances requiring sterile environments and barrier layers, Grade 3003 H24 foil is used to safely package medical devices and pharmaceutical products, securing contents from moisture and contamination.

-

Construction and Insulation: This aluminum foil also plays a critical role in building insulation, acting as a radiant barrier in walls and roofs, reflecting radiant heat while serving as a durable moisture barrier.

-

Automotive and Electrical Components: Certain parts demand lightweight yet strong materials with decent thermal conductivity — traits that 3003 H24 aluminum foil provides, used in heat shields, gaskets, and even electromagnetic shielding layers.

-

Consumer Goods and Decorative Items: Thanks to its smooth surface and ability to receive anodizing or printing, 3003 H24 foil finds its way into decorative laminates, doll costume materials, and even art projects where lightweight and shine are desirable.

Why Choose Grade 3003 H24 Aluminum Foil?

The incomparable value of this aluminum foil lies in its reliability under both industrial and everyday conditions. Its moderate strength does not compromise flexibility, making operations like folding, bending, and crimping practical and efficient without material failure. Moreover, its environmentally friendly nature — highly recyclable with energy-efficient processing — appeals to modern sustainability demands.

In sum, Grade 3003 H24 aluminum foil is a surprisingly powerful solution behind numerous products and processes, combining strength, versatility, and durability. Whether safeguarding your food or enhancing industrial functionality, it proves that sometimes the best materials are found in the quiet details, supporting convenience and performance with quiet efficiency.

https://www.al-alloy.com/a/grade-3003-h24-aluminum-foil.html