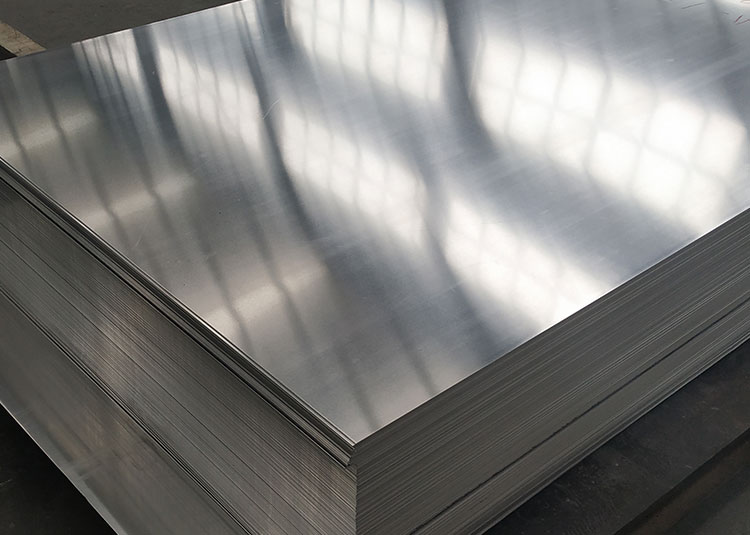

Aluminum plate metal 1/4

Aluminum Plate Metal 1/4": A Subtle Hero in Everyday Metalwork

When you hear “1/4 inch aluminum plate,” your mind might zoom straight to big industrial projects or shiny aircraft parts.

Thickness That Strikes a Balance

So why 1/4 inch? Well, this thickness hits a sweet spot between strength and flexibility. It’s robust enough to handle heavy-duty tasks yet still manageable in workshops and fabrication settings. Unlike thinner sheets that can bend or warp easily, the quarter-inch plate stands resilient under stress without being overly bulky.

Working with 1/4" aluminum plate presents a unique set of challenges and opportunities compared to thinner gauges. Its increased thickness makes it significantly stronger and more rigid, ideal for applications demanding high durability and load-bearing capacity. However, this strength comes at the cost of increased machining difficulty. We often see issues with tool wear during milling or drilling, requiring specialized tooling and potentially slower feed rates to prevent chipping or tear-out. Furthermore, the greater mass necessitates more powerful equipment for bending or forming, and careful consideration of potential warping during welding. A common issue is finding the optimal balance between strength and efficient processing, often leading us to explore different alloy compositions or heat treatments to tailor the material's properties for specific applications.

One area where we've seen significant improvements is in surface finish. While the thicker gauge inherently provides better scratch resistance, the increased material removal during finishing can be costly. We've experimented with different abrasive techniques and optimized parameters to minimize waste and achieve desired surface quality. Beyond the mechanical aspects, the specific alloy of the 1/4" aluminum plate is crucial. Variations in alloying elements significantly impact corrosion resistance, weldability, and machinability. For instance, 6061 aluminum plate offers a good balance of strength and workability, while 5052 is preferred for its superior corrosion resistance in marine environments. This knowledge guides our material selection and allows us to advise clients on the best

What Makes It Tick?

Aluminum in this thickness typically consists of alloys like 6061 or 5052, known for their balance of strength and corrosion resistance. Heat-treatable alloys like 6061 can be zipped through welding and bending processes without losing structural integrity. Plus, the natural oxide layer on aluminum provides a handy shield against rust, making the metal essentially maintenance-free indoors and out.

Functional Beauty in Applications

This metal shines quietly across many markets. Take automotive: 1/4 inch aluminum plates often form protective skid plates under vehicles, shielding critical parts from rocks and detritus. In marine environments, this plate takes up its fortitude on boat hulls and fishing equipment due to its lightweight but sturdy nature resisting saltwater corrosion.

For architects and interior designers, the quarter-inch plate doubles as custom cladding or decorative wall panels. It balances subtle metallic sheen with structural utility, keeping projects visually clean while mechanically sound. And why not workshops? From machinery parts to DIY tabletops, it’s big enough to build sturdy fixtures and light enough for typical shop hand tools.

Manufactured With Versatility in Mind

Speaking of shop tools, this thickness cleaves nicely with saws, responds well to milling, and can be precision laser cut for complex shapes. The machinability combined with decent thickness means designers don’t have to limit their creativity at the scrap pile. This also aligns well with pulse welding and anodizing, broadening finishing options—from functional corrosion resistance up to sleek metallic styling.

Aluminum in Perspective

Compared to steel plates of the same thickness, aluminum’s significant weight reduction—approximately one-third that of steel—brings mobility and ease of installation. Also, don’t underestimate thermal and electrical conductivity traits; this plate, while strong, can double as a heat sink basis in electronics or industrial process setups.