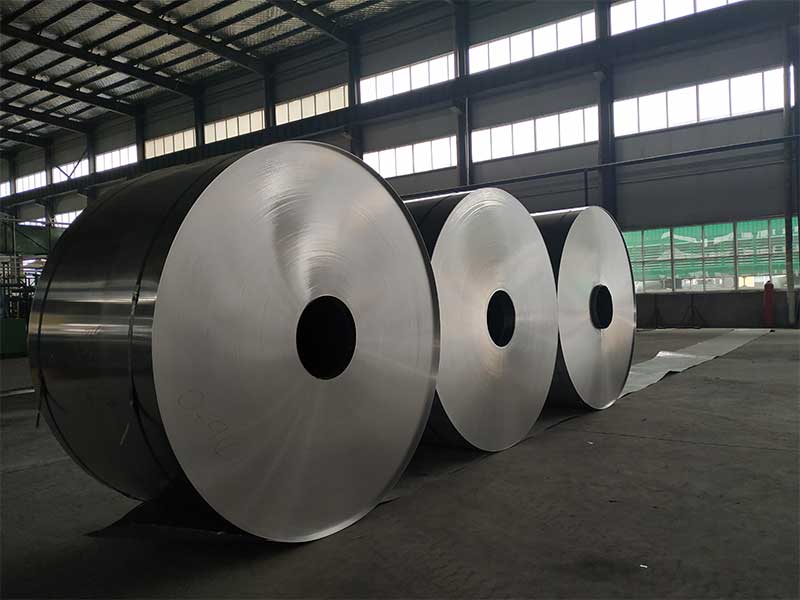

Prepainted 1050 Aluminum Coil Roll

Prepainted 1050 Aluminum Coil Roll: Features and Applications

In the world of modern manufacturing and construction, the choice of materials can make or break a project. Among the multitude of options available, the Prepainted 1050 Aluminum Coil Roll stands out, combining lightweight properties with remarkable durability and aesthetic appeal. this material and its applications opens doors to innovative solutions in various industries.

Working with prepainted 1050 aluminum coil rolls presents a unique set of challenges compared to bare aluminum. The 1050 alloy itself is relatively soft and easily scratched, requiring careful handling throughout the entire process, from initial unloading to final shipment. The added pre-painted layer further complicates things. We have to be extra vigilant about avoiding any surface damage during slitting, embossing, or any other downstream processes. The paint's adhesion and its resistance to various chemicals and environmental factors are crucial considerations, particularly in meeting customer specifications for outdoor applications. A seemingly minor defect, like a slight scratch or a pinhole, can lead to significant rework or even rejection of the entire roll, making quality control exceptionally stringent.

Personally, I find the color consistency and finish of the prepainted coils to be a fascinating aspect. We receive rolls in a wide array of colors and textures, each demanding specific processing parameters to avoid imperfections. the interplay between the paint formulation, the aluminum substrate, and the various processing steps is a continuous learning experience. It’s a constant balancing act between speed and precision, always striving for optimal output while minimizing waste and maintaining the highest possible quality. The satisfaction of seeing a flawless, brilliantly colored coil roll emerge from the line, ready for its final application, is a rewarding testament to the precision and teamwork involved in this process.

What is Prepainted 1050 Aluminum Coil Roll?

At its core, the 1050 aluminum alloy is renowned for its high corrosion resistance and excellent workability. It consists of over 99% pure aluminum, which contributes to its flexibility and resistance to oxidation. When this base material is prepainted, it is coated with a layer of high-quality paint, typically through a continuous coil coating process. This ensures that the final product not only retains the intrinsic benefits of aluminum but also boasts vibrant colors and enhanced surface protection.

Exceptional Features of Prepainted 1050 Aluminum Coil Roll

-

Corrosion Resistance: One of the defining characteristics of 1050 aluminum is its resistance to corrosive environments. This makes prepainted rolls ideal for applications in coastal areas or industries where exposure to oxidizing agents is common.

-

Lightweight Nature: With its low density, 1050 aluminum offers a solution that significantly reduces the overall weight of constructions without sacrificing strength or performance, contributing to fuel efficiency in transportation sectors.

-

Aesthetic Versatility: The prepainting process allows for a stunning variety of colors and finishes, making the coils a popular option for architectural facades and decorative elements. The paint also protects against UV rays, ensuring that colors remain unchanged for longer periods.

-

Thermal and Electrical Conductivity: Although commonly appreciated for its lightweight properties, the 1050 alloy also exhibits effective thermal and electrical conductivity. This duality makes it appealing for equipment requiring efficient heat dissipation, such as heat exchangers.

-

Ease of Fabrication: The formability of prepainted 1050 aluminum lends itself well to bending, cutting, and folding without compromising the integrity of the finish. This provides manufacturers with enhanced versatility to create intricate designs seamlessly.

Applications Across Industries

The breadth of usability for Prepainted 1050 Aluminum Coil Roll is , spanning multiple sectors, including:

-

Architectural: In constructing rain-handling systems, roofing, and decorative panels, the combination of rust resistance, aesthetics, and formability make prepainted coils a preferred choice for architects and builders striving for both function and allure.

-

Interior Decor: Inside, these coil rolls can be transformed into wall panels, ceilings, and decorative partitions due to their lower weight and stunning finishes, creating inviting spaces without undue structural stress.

-

Signage: The retail and business sectors benefit from prepainted 1050 aluminum signs, which can vary from sleek corporate branding to vibrant promotional materials, thanks to high-quality prints that withstand the harsh effects of sunlight.

-

Transportation: From vehicle body panels to personal watercraft, the lightweight feature of prepainted aluminum increases fuel efficiency and overall performance without compromising durability.

-

Air Conditioning and Refrigeration: In HVAC systems, the high conductivity properties allow for efficient performance in heating and cooling units, supporting cost-effective and energy-efficient temperature control solutions.

https://www.al-alloy.com/a/prepainted-1050-aluminum-coil-roll.html