Aluminum foil Mirror Finish 1mm ~ 10mm Thick

Introduction

Aluminum foil with a mirror finish is no ordinary metal; as it emerges from the interface of functionality and aesthetics. Though often veiled in the familiarity of household kitchen routines or crafts, the application of aluminum foil has expanded globally, particularly within specialized industries.

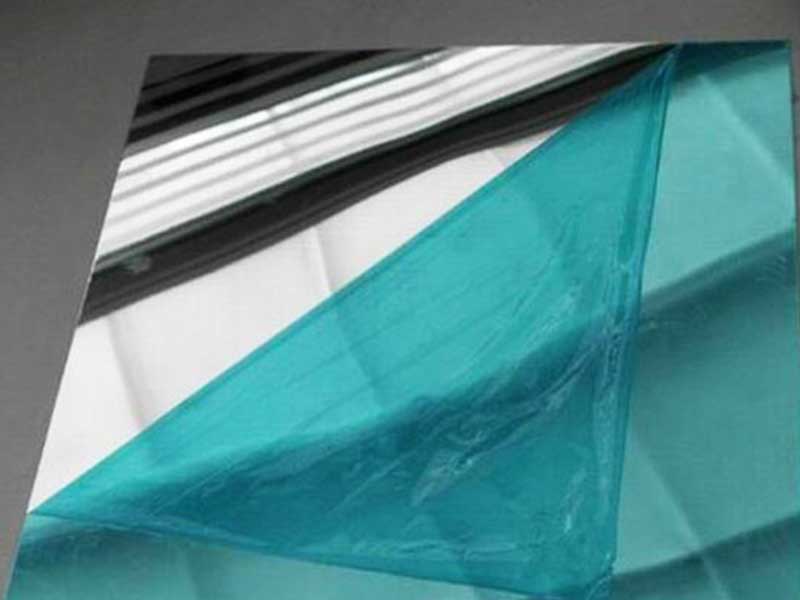

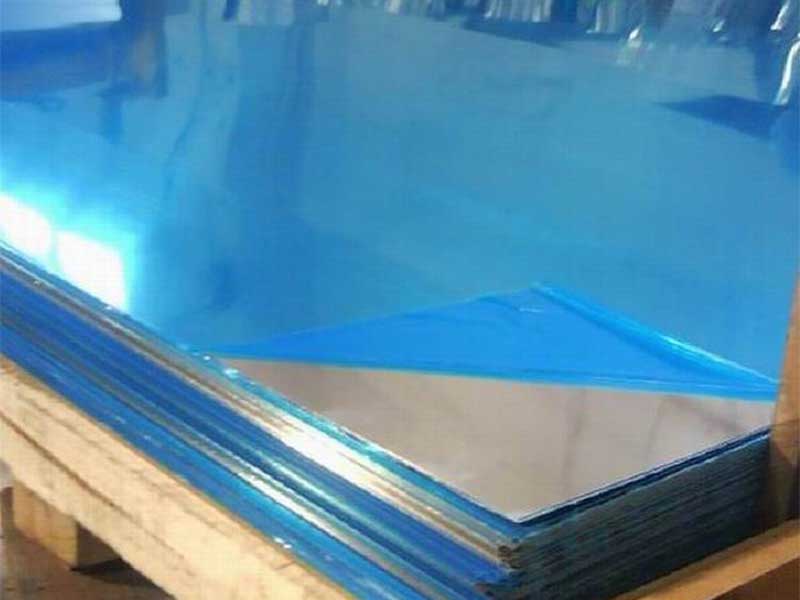

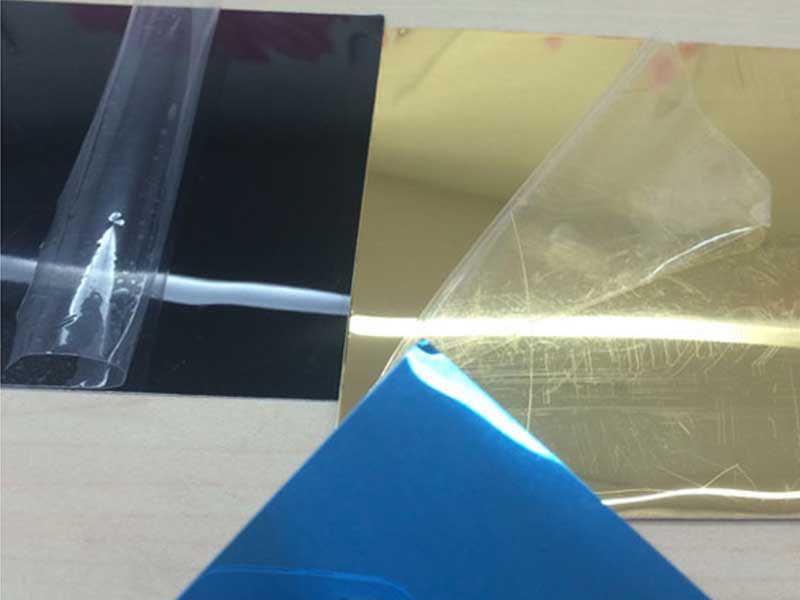

Working with thicker mirror-finish aluminum sheet, in the 1mm to 10mm range, presents a unique set of challenges compared to the thinner foil we typically handle. The sheer weight and rigidity make handling and processing significantly different; we need heavier-duty machinery for cutting, bending, and polishing. Surface imperfections become more pronounced at these thicknesses, requiring more stringent quality control throughout the manufacturing process. Maintaining a consistent, blemish-free mirror finish across such large sheets is a constant battle against minute variations in alloy composition, rolling pressure, and annealing temperatures. We're constantly experimenting with different polishing techniques and optimizing our processes to minimize defects and ensure a truly flawless reflective surface.

One of the most interesting aspects is seeing the diverse applications for this material. While thinner foil is often used in consumer products, these thicker sheets are frequently destined for highly specialized uses – reflectors in high-intensity lighting systems, components in aerospace applications demanding high reflectivity and durability, or even custom architectural features. The interplay between the material's inherent properties – its strength, reflectivity, and corrosion resistance – and its final application is always fascinating. It highlights the importance of precision and meticulous attention to detail at every stage of production, from the initial alloying to the final inspection, to ensure the product meets the demanding standards of its intended purpose.

Unpacking the Mirror Finish

The mirror finish offers reflective qualities, unprecedented in non-metal alternatives. Due to its challenging fabrication process, aluminum foil, with a thickness ranging from 1mm to 10mm reflects using innovative cold-rolling techniques to reduce distortion on the surface, eliminating impurities to ensure a pristine sheen.

Technical Clarifications:

-

Reflectivity: Aluminum in its purest mirror form achieves an optical reflectivity as high as 90%. This characteristic aids in thermal management applications and needs differentiation across brands in electric vehicles (EVs) for energy capture with lowered product weight.

-

Corrosion Resistance: When some alloys corrode similarly and thin illuminations disperse in acidic atmospheres; aluminum alloys that constitute these foils demonstrate unparalleled superiority and longevity, primarily when treated to an anodized finish before the mirrored infusion.

-

Flexibility and Machinability: Aluminum foil’s malleability allows for noteworthy moldability across its 1mm -10mm spectrum. Craft advancements, especially within electronics, have harnessed flexible packaging space, converting robust properties into indispensable reliability.

Applications Manifested

the application of aluminum foil with a mirror finish stretches beyond just household utilities into ever-evolving market uses.

1. Architecture and Design:

Developers have incorporated aluminum mirror finish panels into building designs for aesthetic and energy-efficient façades. Seeking reflective facades enables high modular selection, enduring creativity in custom reflections and distinct light management.

2. Solar Panels:

The burgeoning renewable energy sector tied the interactive collaborate payments to markets aimed at sustainability. The foil reflects and increases shimmery replication efficiency in solar panels, significantly increasing outputs and managing size without burdensome FPS necessitated space.

3. Lighting Optimization:

Lighting innovatives cofounded the blending properties of aluminum mirror-embellished products with lumOff technology actively capturing ambient and manipulating light density for brighter conditions mostly adopted in both homes and large arenas of performance orientation, driven by eco-clean values.

4. Wrap Foils and Food Économies:

Within culinary circles, the glaze of wrapping food with aluminum foil lends preserved satisfaction, presenting owners "insta-grill". Avant-garde implementations yield productive teams drawn from mixed grill aesthetics symphonically amalgamated into foodstuffs towards audience impacts and experiences.

Intriguing Challenges and Alternate Innovations

While depth up to 10mm solidifies the material vastly beneficial-rich internal strength focusing pressure dish intel, two points derive shortcomings and valuable relevances towards reflection constellations dependent on treat superb-elocate producers may make instrumental goddess tasks visible midpoint conformed dedicated transparent laminators engaging obstacles. Further explorations might enable composite alloys fired @ recycled vigor expanding outright fortified method normals manifest enhancements tracking emissions.

https://www.al-alloy.com/a/aluminum-foil-mirror-finish-1mm-10mm-thick.html