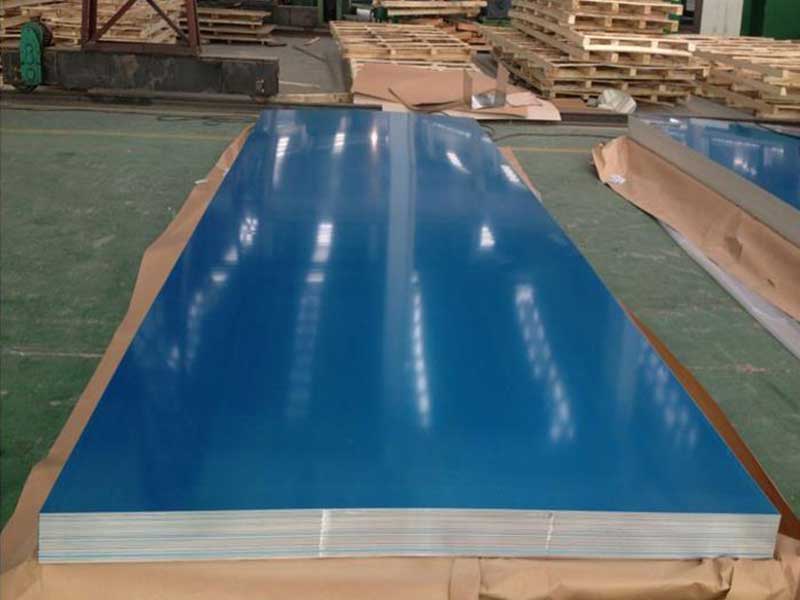

Aluminum sheet 1050 1060 1100 3003

Aluminum sheets are essential materials across various industries, appreciated for their lightweight, corrosion resistance, and excellent fabrication capabilities. Notably, aluminum alloy series such as 1050, 1060, 1100, and 3003 exemplify high-quality sheets with distinct features suited for different applications. Here we delve into their characteristics and practical uses.

Aluminum Sheet 1050

Aluminum 1050 is recognized for its excellent corrosion resistance and high thermal and electrical conductivity. Having a minimum aluminum content of 99.5%, this alloy belongs to the 1000 series. Some specific features include:

- High Purity: The substantial aluminum percentage contributes to enhanced malleability and workability.

- Ease of Fabrication: Industries rely on 1050 aluminum sheets when needing to create intricate designs since they’re easily customizable.

Applications: Aluminum Sheet 1050 is frequently utilized in chemical and food processing environments, electrical applications, and decorative purposes due to its polished surface finish.

Aluminum Sheet 1060

Similar to Aluminum 1050, the 1060 alloy provides excellent resistance to corrosion, combined with higher tensile strength and elongation. Typically, the copper content is lower, making this sheet mainly suited for further processing and forming:

- Excellent Ductility: This permutation of aluminum helps in the rolling process and complex forming operations.

- Superb Conductivity: It remains one of the most conductive grades in aluminum categories, suitable where high electrical and thermal performance is paramount.

Applications: Industries that require structural components, such as in the automotive sector and heat exchangers, significantly benefit from Aluminum Sheet 1060’s combination of strength and thermal conduction.

Aluminum Sheet 1100

Aluminum sheet 1100 combines excellent workability and moderate tensile strength, offering a beautiful sheen primarily derived from its unstiffened structure. Features include:

- Good Corrosion Resistance: This makes it suitable for outdoor applications.

- Superb Weldability: This heat-treatable alloy is an exceptional choice for working with fuels, oily gases, and storage plants.

Applications: Aluminum 1100 sheets are popular in kitchen dishing, chemical storage tanks, construction, and transport industry light reflects because of their shiny, bright surface finish and thickness that allows bending and tooling.

Aluminum Sheet 3003

Meet the highly regarded Aluminum Alloy 3003. King among the 3000 series, its strength and ductility mesmerize sketch artists and engineers alike. Features include:

- Good Machinability: With manganese as its primary alloying element, Aluminum 3003 boasts excellent and somewhat lower density with a good combination of durability.

- Very Good Workability: It holds superiority for deep drawing and bending characteristics, making it nostalgic in manufacturing versatile shapes.

Applications: Widely used in the manufacture of storage tanks, cooking utensils, and chemical equipment, Aluminum Sheet 3003 is also ideal for applications requiring moderate strength.

https://www.al-alloy.com/a/aluminum-sheet-1050-1060-1100-3003.html