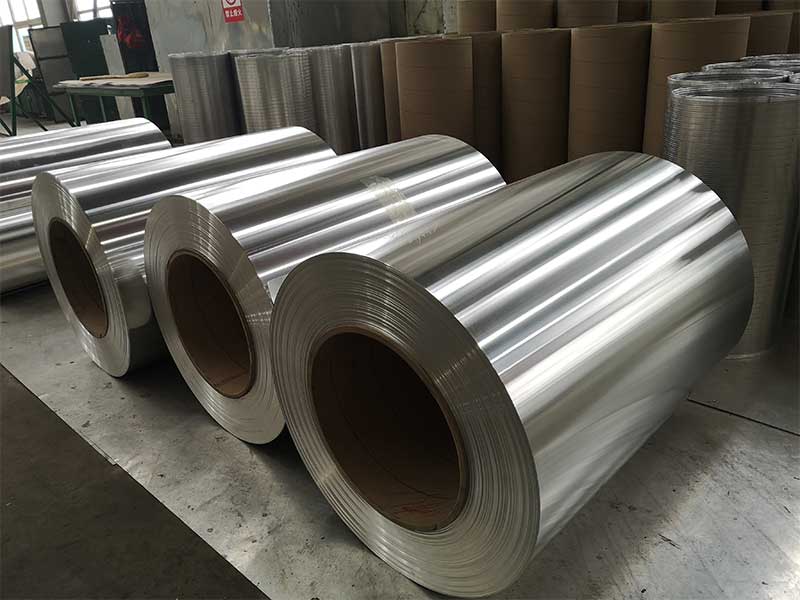

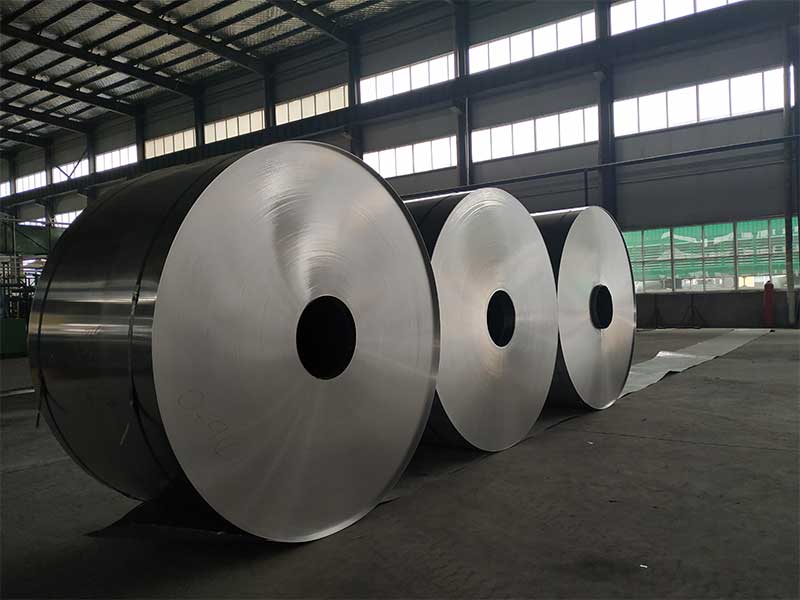

Thin aluminum coil

In a world where light-weight materials are increasingly pivotal to the optimization of designs, thin aluminum coil emerges not just as a material but as a revolutionary tool in various industries. Often overshadowed by bulkier metals, this slender champion boasts an array of unique features that position it as an essential component across numerous applications.

The Unique Features of Thin Aluminum Coil

-

Lightweight and Flexibility: Thin aluminum coils offer an appealing alternative to traditional metals, maintaining high strength while drastically reducing weight. This characteristic makes them easy to manipulate and transport, enhancing their adoption in industries such as aerospace and automotive.

-

Superior Corrosion Resistance: Aluminum coils naturally form a protective oxide layer when exposed to air. This means that even the thinnest of these coils can withstand environmental stressors, making them ideal for outdoor applications. The corrosion resistance also assures longevity in products, reducing maintenance costs in the long run.

-

High Thermal Conductivity: An underrated feature, the thermal conductivity of thin aluminum coil renders it highly effective in heat exchange applications. This makes it a favored choice in HVAC systems and electronics where efficient cooling is paramount.

-

Ductility and Malleability: The ability to be easily shaped into various forms without fracturing gives thin aluminum coils an edge in innovative manufacturing. Whether through stamping, bending, or slitting, manufacturers can create intricate designs that meet specific criteria.

-

Electrical Conductivity: While often overlooked, the electrical conductivity of aluminum allows for unique applications in electrical-related design. The lightweight yet effective nature of thin coils is suited for power lines and other electrical components.

Diverse Applications across Industries

Thin aluminum coils have graced multiple sectors, providing tailor-made solutions that frequently exceed the performance of other materials.

-

Aerospace Industry: In an industry where weight is critical for fuel efficiency, thin aluminum coils are utilized in the manufacturing of aircraft skin, interiors, and components to minimize overall mass while maintaining structural integrity.

-

Automotive Manufacturing: The shift toward electric fleets necessitates lightweight materials to enhance the efficiency of energy use. Thin aluminum coils find applications in battery housing and structural elements, helping manufacturers build vehicles that are both strong and light.

-

Construction and Architectural Designs: Architects and builders leverage thin aluminum coils for modern designs that incorporate aesthetic qualities along with resilience. They’re often used for roofing, cladding, and even facades, highlighting not only sustainability but also energy efficiency.

-

Electronics: In household devices, thin aluminum coils play a crucial role in heat dissipation and electrical conduction. By forming heat sinks or structural frameworks, manufacturers ensure their products perform optimally without overheating.

-

Packaging Industry: The robust, yet lightweight qualities of thin aluminum coils also extend into the packaging realm. Beverage cans, food containers, and even certain types of insulation materials utilize these coils, benefiting from their protective qualities and sustainability.