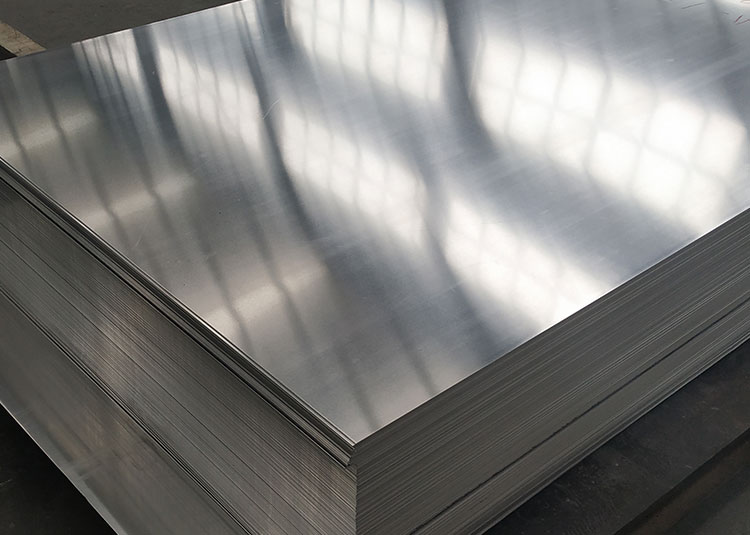

Aluminum sheet Thickness 1 Mm 2mm 3mm 4mm

Aluminum sheets in varying thicknesses—1mm, 2mm, 3mm, and 4mm—might not be the hottest topics trending on social media, but they’re the unsung heroes supporting countless everyday operations and projects.

The Basics: Why Thickness Matters

When we start talking about aluminum sheets, it’s all about striking a balance between weight, strength, and flexibility. The thickness plays a pivotal role in determining these factors, making it essential to know how they affect application:

Working with aluminum sheet in thicknesses of 1mm, 2mm, 3mm, and 4mm daily reveals fascinating differences in their handling and application. The 1mm sheet, while lightweight and easy to manipulate, requires careful handling to prevent bending or scratching during processing. Its thinner gauge makes it ideal for applications requiring flexibility and formability, like intricate parts in automotive or electronics manufacturing. However, its fragility means it's more susceptible to damage during shipping and requires more delicate tooling. Conversely, the 4mm sheet presents a different challenge; its thickness requires more powerful machinery for cutting and forming, and its weight impacts storage and transport logistics. It's the workhorse of the thicker gauges, often used in applications demanding high strength and durability.

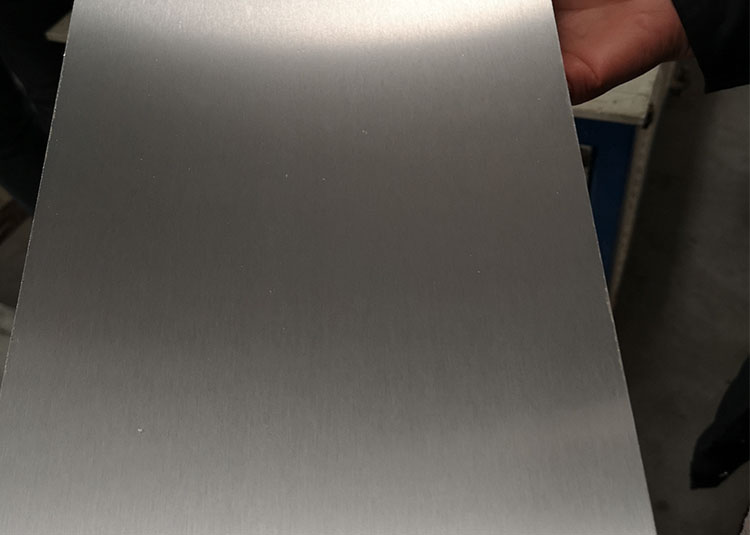

Personally, I've noticed a correlation between sheet thickness and the types of defects we encounter. Thinner sheets (1mm and 2mm) are prone to surface imperfections like scratches and minor inconsistencies in gauge, mostly due to the manufacturing process itself. Thicker sheets, while less susceptible to surface damage, can show internal defects like inclusions or porosity, which are harder to detect visually. these tendencies is crucial for optimizing our quality control procedures and predicting potential issues down the line. This involves choosing appropriate testing methods for each thickness and adjusting our machining parameters to mitigate the inherent challenges of each gauge.

-

1mm Aluminum Sheets: If you’re looking for lightweight material that still boasts excellent durability, 1mm thick sheets can be ideal. Typically used in architectural applications, electronic enclosures, or crafts where flexibility comes into play, these sheets offer easy handling and reflect a certain modern aesthetic.

-

2mm Aluminum Sheets: Stepping up in thickness, we find 2mm sheets that welcome a bit more robustness while still keeping it manageable. Vehicle grilles, protective covers, and light furniture still rely on the properties of aluminum and can use this thickness creatively. The combination of strength and lightness has earned trusting applications in the automotive industry.

-

3mm Aluminum Sheets: Here’s where it starts to get interesting, as 3mm sheets offer a perfect entry point for mid-level structural applications. Think structural components, brackets, and frames. The added thickness means better performance under stress while remaining a popular choice across manufacturing sectors.

-

4mm Aluminum Sheets: Last but not least, 4mm sheets shine in heavy-duty applications. These thicker sheets bestow a sense of sturdiness one craves in large-scale builds—ideal for things like cladding, demanding aerospace parts, and countless industrial machinery. This thickness takes partnership with steel to a whole new level without the urgent weight baggage.

Versatility is Key

What’s magical about aluminum? It’s not just the shiny finish or its corrosion-resistance—they come with versatility that slaps a grin on the face of many an engineer and designer! This metal is a robust champion in consumer goods, automotive repair, construction, energy, and even aerospace, showcasing an inequality of traits that other materials often struggle to parallel.

Technical Details Explained: Properties Galore

You might already sense that thickness does not exist in a bubble. Two other primary factors even the slightest metal nerd dreams of are alloy composition and temper. Seasons greetings from forces like corrosion resistance, formability, weldability, m and ease of machining are cells of aluminum’s charm. Several alloy options lean paradigms toward certain functionalities, making their strength compatible with demanding operations.

Do you require weldability in lighter aluminum parts? Choose an alloy from the 5000 series. Is precision and dimensional stability for an architectural masterpiece your goal? An alloy from the 6000 series will share along. Get familiarized and ensure your choices fit meet application requirements.

Everyday Applications: Real-World Riffs

Let’s bring this down to a practical baseline. Virtually, these total-purpose sheets can flit alongside numerous projects. In the DIY realm, they can become stunning wall décor or modern furniture accents. Simply bolting, separating sheets into unique geometric shapes for crafts can establish a distinctive personal touch. Gardens, anyone? Undertaking raised flower beds or lightweight trellises? Yup, aluminum sheets got your back!

In industrial settings, think substrates for power screens, manufacturing prints for LCD panels, or high-performance components in suspension systems. Even kitchen range hoods turn aluminum sheets into change as heavy-duty players in heat distribution.

https://www.al-alloy.com/a/aluminum-sheet-thickness-1-mm-2mm-3mm-4mm.html