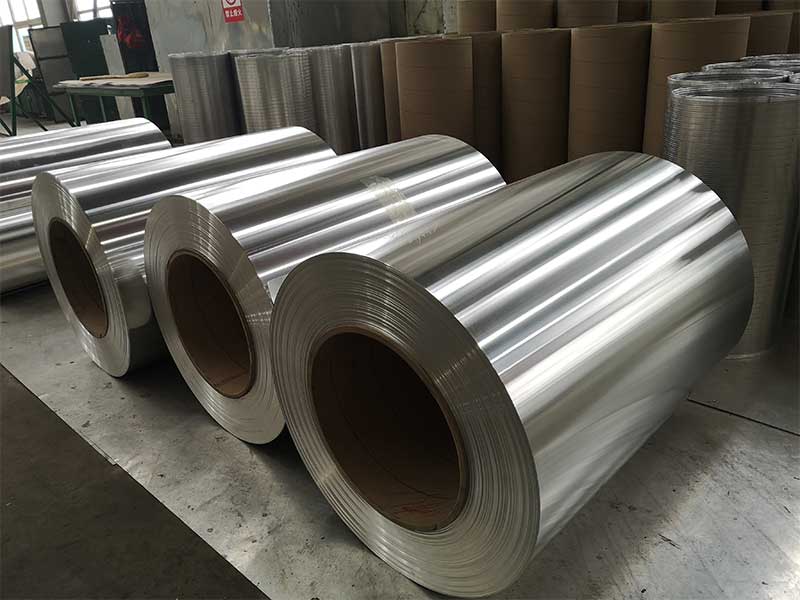

Anodized 1.5 2.0mm Aluminum Coil

As the demand for sustainable, durable, and visually appealing materials in construction and manufacturing surges, anodized aluminum coils are increasingly becoming the go-to choice. Among them, 1.5mm and 2.0mm anodized aluminum coils is know due to their unique combination of mechanical strength and aesthetic appeal.

1. Understanding Anodization

Anodization is an electrochemical process that enhances aluminum by creating a protective oxide layer on its surface. This coating not only protects the aluminum from corrosion and wear but also enables a range of color finishes, making it an excellent material for buildings, vehicle components, and decorative elements. Anodized aluminum coils in thicknesses of 1.5mm and 2.0mm offer lightweight, versatile options ideal for various applications.

2. Benefits of 1.5mm and 2.0mm Anodized Aluminum Coils

a. Enhanced Durability

The anodization process significantly increases the surface hardness of the aluminum coils. The resulting corrosion-resistant barrier ensures that both 1.5mm and 2.0mm coils can withstand harsher environments while maintaining long-term integrity. Architects and builders often appreciate this reliability, especially in commercial and industrial uses.

b. Lightweight Yet Strong

Despite their strength, anodized aluminum coils are lightweight. The 1.5mm thickness is particularly useful when designing structures that require minimal weight without compromising on support or stability. Conversely, the 2.0mm thickness provides enhanced mechanical strength for applications demanding greater load-bearing.

c. Aesthetic Appeal

One of the standout features of anodized aluminum coils is their stunning surface finish. The anodization can produce a variety of colors and textures, enhancing the visual appeal of any project. Whether solid colors, metallic finishes, or custom shades are desired, both 1.5mm and 2.0mm anodized coils can provide architects and designers with the aesthetic versatility they need.

d. Energy Efficiency

Anodized aluminum is excellent for reflecting heat and light, adding energy efficiency to buildings when used as facades or roofing. This characteristic reduces heat absorption, which in turn can lead to significant energy savings.

e. Environmental Sustainability

Purchasing anodized aluminum coils contributes to sustainable construction practices. Aluminum itself is recyclable, and the anodization process does not compromise its recyclability, making 1.5mm and 2.0mm coils an eco-friendly option for businesses looking to reduce their carbon footprint.

3. Applications of Anodized Aluminum Coils

The versatility of 1.5mm and 2.0mm anodized aluminum coils makes them suitable in numerous settings. Here are a few prominent applications:

- Architecture and Construction: Used in facades, window frames, and aluminum signage due to their durability and aesthetics.

- Military Equipment: These aluminum coils provide reliability in defense frameworks that require sturdy yet lightweight materials.

- Automotive and Aerospace: Anodized aluminum is employed in parts and components where weight saving is vital without sacrificing strength.

- Food Processing and Packaging: As anodized aluminum is resistant to corrosion and strictly antibacterial, it’s ideal for various surfaces including food processing equipment.

https://www.al-alloy.com/a/anodized-15-20mm-aluminum-coil.html