Marine Grade 5052-h32 5083 5086 10mm Thick Aluminium Sheet

Marine Grade 5052-H32, 5083, 5086 10mm Thick Aluminium Sheet: The Unsung Hero of the Seas

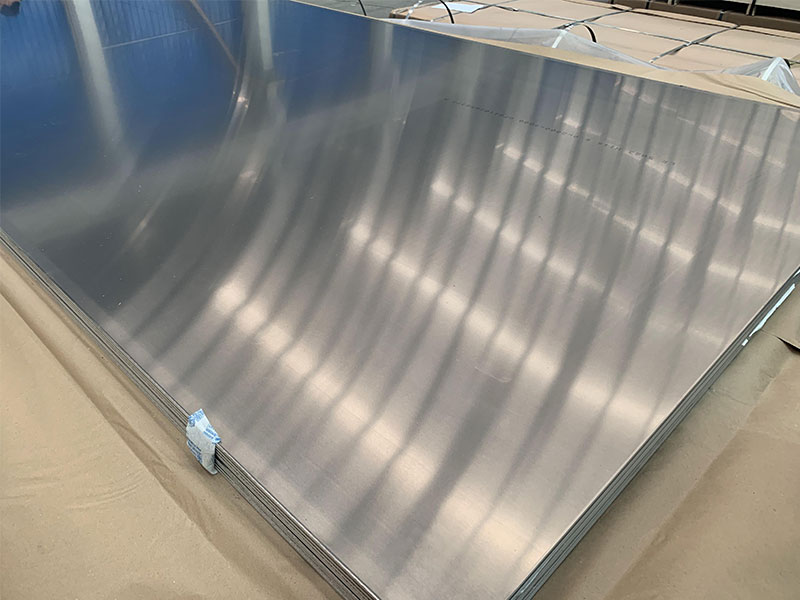

When you think of boats and ships cruising through choppy waters or docked at sun-drenched marinas, your mind might jump to sleek designs or powerful engines. But hidden behind the scenes—and under those shiny paint jobs—are some sturdy workhorses: marine grade aluminum sheets. In particular, the alloys 5052-H32, 5083, and 5086, especially around 10mm thick, are quietly making waves for their ability to stand up to harsh marine environments.

Why Marine Grade Aluminium?

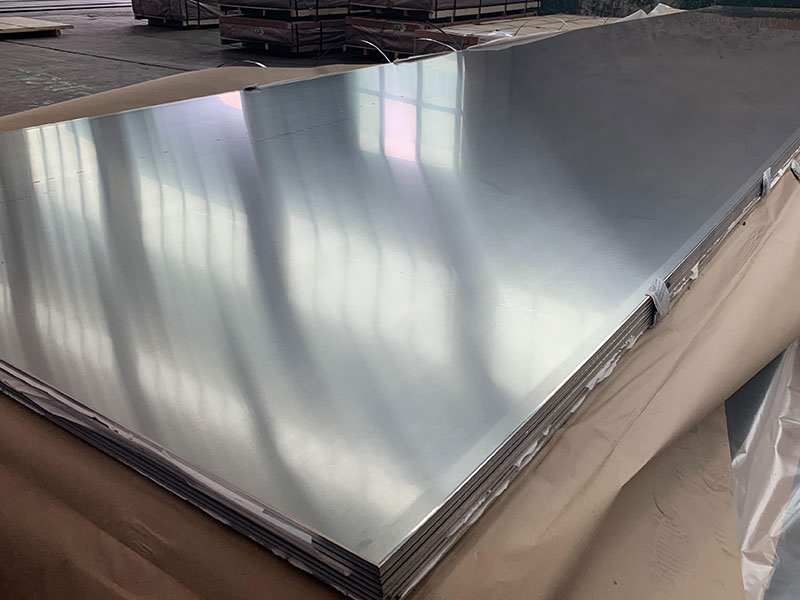

Before we zoom into the specific alloys, it’s worth appreciating what “marine grade” really means. It’s not just a marketing phrase. Marine grade aluminum is specially engineered to deal with sea water, salt sprays, and constant humidity—things that quickly turn ordinary metals rusty and weak. The key: these alloys are high in magnesium and others, offering incredible resistance to corrosion, especially the nasty kind wrought by salt water.

Breaking Down the Players: 5052-H32, 5083, and 5086

-

5052-H32 Think of 5052 as the versatile team player. The H32 temper means it’s cold-worked for extra strength while retaining excellent ductility. One of the standout features of 5052 is its amazing resistance to saltwater and marine atmospheres due to its magnesium content (about 2.5%). That’s why you’ll find 5052-H32 in pontoons, fuel tanks, and boat hulls that need a solid balance between formability and toughness.

-

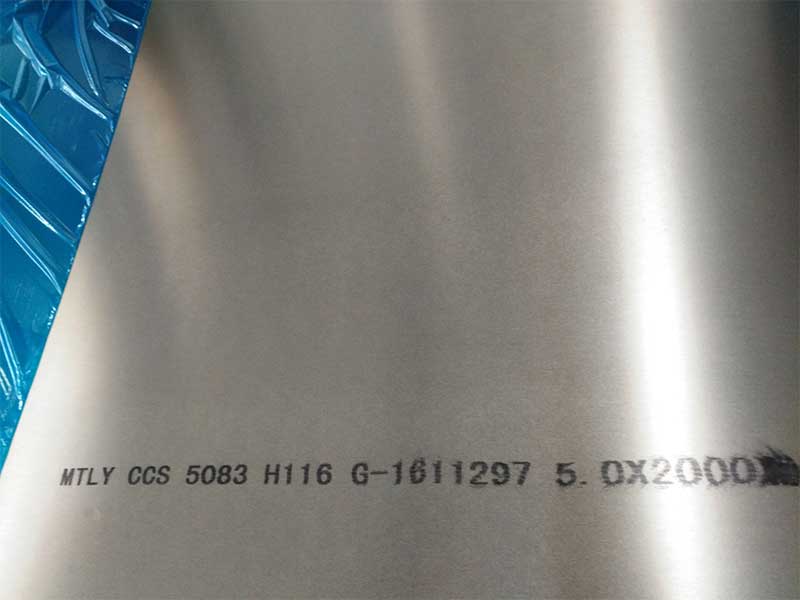

5083 Step up for higher demands, and 5083 shines. With a magnesium boost of around 4-4.9% plus small portions of manganese and chromium, 5083 offers rugged strength combined with top-tier corrosion resistance even under heavy welding conditions. It’s a favorite for shipping vessels and hulls requiring extra toughness against impacts and attacks from corrosive sea environments.

-

5086 Close cousin to 5083, alloy 5086 adds just a hint of maneuverability for fabricators while maintaining a solid armor against salt corrosion. It offers exceptional fatigue strength and weldability, making it the trusted choice in meticulous applications like superyachts, military boats, or offshore platforms where endurance is everything.

Thickness Matters: Why 10mm?

Choosing a 10mm thick aluminium sheet aligns well with projects needing deepest assurance against dents, seawater pressure, and structural challenges without overly bumping up weight. 10mm is thick enough to provide robustness but still manageable when it comes to machining or welding. For the marine industry, where every kilogram counts onboard, this balance translates directly into performance and durability.

Real World Applications: Function Meets Form

These 10mm thick marine grade aluminium sheets find themselves in:

- Hull Construction: Providing the main shell of boats that take everything from storm waves to rogue debris in stride.

- Decking and Superstructures: Tough on corrosion, but still lightweight, ensuring ships stay top-heavy free.

- Fuel Tanks & Storage Compartments: Thanks to non-toxic qualities and corrosion resistance, these sheets make safe, long-lasting enclosures.

- Marine Fittings & Equipment: Everything from ladders to davits, benefiting from high mechanical strength combined with resistance to salt and UV exposure.

Wrapping Up: Metal That Keeps Your Boat Sailing Smoothly

The magic of marine grade 5052-H32, 5083, and 5086 aluminium sheets at 10mm thickness is that they balance the sailor’s dream—strength, corrosion resistance, formability, and light weight—all in one neat package. They quietly protect vessels, offering a safeguard that, most times, only engineers and experienced boat-builders truly appreciate. So next time you spot that gleaming boat at the harbor, remember those solid metal sheets working below the surface to keep adventures afloat.

https://www.al-alloy.com/a/marine-grade-5052-h32-5083-5086-10mm-thick-aluminium-sheet.html