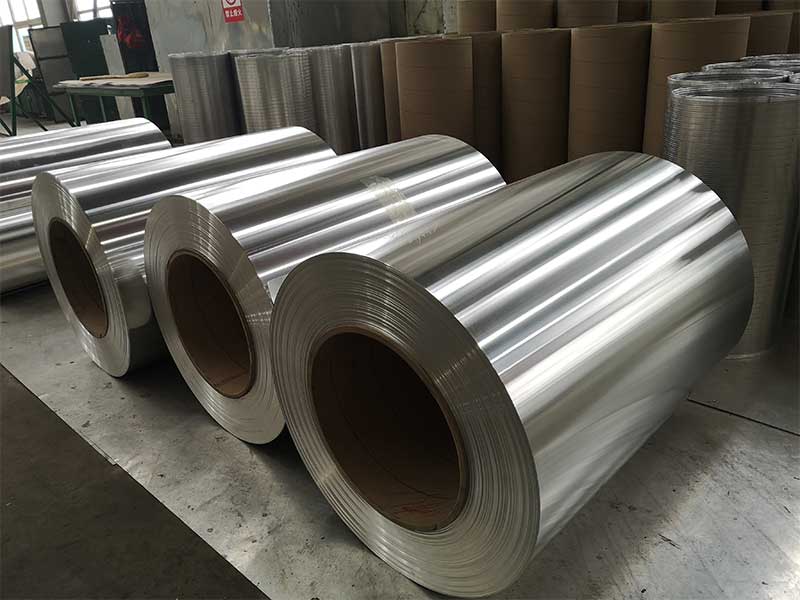

5052 5754 7075 6061 Alloy Roll Aluminum Coil

Exploring the Versatility of Aluminum Coil Alloys: 5052, 5754, 7075, and 6061

Aluminum coils are a staple in various industries due to their lightweight yet strong properties. Among the vast array of aluminum alloys, 5052, 5754, 7075, and 6061 stand out for their unique characteristics and wide-ranging applications. This article delves into each alloy, showcasing their properties, uses, and why they are the go-to choice for engineers and manufacturers alike.

1. 5052 Aluminum Alloy Coil

5052 aluminum alloy is well-known for its excellent corrosion resistance, formability, and weldability. With a medium strength compared to other alloy types, it is often used in marine and automotive applications. The Features of 5052 aluminum coil include:

- Corrosion Resistance: Ideal for environments exposed to saltwater and chemicals.

- Formability: Easily shaped and bent, making it great for complex applications such as the construction of tanks, pressure vessels, and HVAC applications.

- Weldability: Its ability to be easily welded means it is a popular choice in structural applications.

2. 5754 Aluminum Alloy Coil

5754 aluminum alloy is recognized for its toughness and ability to resist fatigue, which makes it invaluable in the construction and automotive sectors. Key highlights include:

- Good Weldability and Formability: Similar to the 5052, 5754 can be processed into sheets and coils that are easy to work with, making it a preferred material for shipbuilding and structural applications.

- Enhanced Strength: With higher strength than 5052, the 5754 grade is ideal for heavy-duty applications, such as chassis components and vehicle body structures.

- Corrosion Resistance: Its durability against marine environments and chemicals helps maintain the integrity of structures over time.

3. 7075 Aluminum Alloy Coil

7075 aluminum alloy is a high-strength option in the aluminum alloy family and is often utilized for aerospace applications due to its superior mechanical properties.

- High Strength-to-Weight Ratio: This alloy provides the structural integrity required for airplane frames and automotive tools while keeping manufacturing lightweight.

- Heat Treatment: 7075 can be heat treated to optimize its strengths, making it perfect for demanding applications.

- Applications: Commonly used in military and aerospace applications, as well as bike frames, where performance and weight savings are critical.

4. 6061 Aluminum Alloy Coil

6061 aluminum alloy is one of the most popular alloys in the world, known for its versatility and good mechanical properties. It is a favorite among engineers for many applications:

- Versatility: Thanks to its good corrosion resistance, weldability, and ease of machining, it can be found in everything from architectural applications to automotive and marine components.

- Lightweight and Strong: Ideal for structural components that require enhanced mechanical properties without adding excessive weight.

- Customizability: Available in various forms including sheets, extruded plates, and coils, allowing for flexibility in design and application.

https://www.al-alloy.com/a/5052-5754-7075-6061-alloy-roll-aluminum-coil.html