1050 ALUMIUNM COIL DESCRIPTION:

1050 aluminum alloy is a series of products, 1050 aluminum coil with high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity characteristics, but the intensity is low, not through the heat treatment strengthening, cutting is not good, acceptable contact welding, gas welding . According to the international nomenclature, the aluminum content must be above 99.5%. Because it does not contain other technical elements, so the production process is relatively simple, the price is relatively cheap, is currently the most commonly used in a series of conventional industries.

1050 ALUMINUM COIL CHEMICAL COMPOSITION:

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.15 | 99.5 |

1050 ALUMINUM COIL MECHANICAL PROPERTIES:

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation | ||||||||

| Thickness(mm) | (MPa) | (MPa) | (%) | |||||||||

| 1050-O/ 1050-H111 | 0.2-0.5 | 65-95 | Min20 | Min20 | ||||||||

| 0.5-1.5 | Min22 | |||||||||||

| 1.5-3.0 | Min26 | |||||||||||

| 3.0-6.0 | Min29 | |||||||||||

| 6.0-12.5 | Min35 | |||||||||||

| 12.5-80.0 | ||||||||||||

| 1050-H112 | 6.0-12.5 | Min75 | Min30 | Min20 | ||||||||

| 12.5-80.0 | Min70 | Min25 | ||||||||||

| 1050-H12 | 0.2-0.5 | 85-125 | Min65 | Min2 | ||||||||

| 0.5-1.5 | Min4 | |||||||||||

| 1.5-3.0 | Min5 | |||||||||||

| 3.0-6.0 | Min7 | |||||||||||

| 6.0-12.5 | Min9 | |||||||||||

| 12.5-40.0 | ||||||||||||

| 1050-H14 | 0.2-1.5 | 105-145 | Min85 | Min2 | ||||||||

| 1.5-3.0 | Min4 | |||||||||||

| 3.0-6.0 | Min5 | |||||||||||

| 6.0-12.5 | Min6 | |||||||||||

| 12.5-25 | ||||||||||||

| 1050-H16 | 0.2-0.5 | 120-160 | Min100 | Min1 | ||||||||

| 0.5-1.5 | Min2 | |||||||||||

| 1.5-4.0 | Min3 | |||||||||||

| 1050-H18 | 0.2-0.5 | Min135 | Min120 | Min1 | ||||||||

| 0.5-1.5 | Min140 | Min2 | ||||||||||

| 1.5-3.0 | Min2 | |||||||||||

| 1050-H19 | 0.2-0.5 | Min155 | Min140 | Min1 | ||||||||

| 0.5-1.5 | Min150 | Min130 | ||||||||||

| 1.5-3.0 | ||||||||||||

| 1050-H22 | 0.2-0.5 | 85-125 | Min55 | Min4 | ||||||||

| 0.5-1.5 | Min5 | |||||||||||

| 1.5-3.0 | Min6 | |||||||||||

| 3.0-6.0 | Min11 | |||||||||||

| 6.0-12.5 | Min12 | |||||||||||

| 1050-H24 | 0.2-0.5 | 105-145 | Min75 | Min3 | ||||||||

| 0.5-1.5 | Min4 | |||||||||||

| 1.5-3.0 | Min5 | |||||||||||

| 3.0-6.0 | Min8 | |||||||||||

| 6.0-12.5 | ||||||||||||

| 1050-H26 | 0.2-0.5 | 120-160 | Min90 | Min2 | ||||||||

| 0.5-1.5 | Min3 | |||||||||||

| 1.5-4.0 | Min4 | |||||||||||

| 1050-H28 | 0.2-0.5 | Min140 | Min110 | Min2 | ||||||||

| 0.5-1.5 | ||||||||||||

| 1.5-3.0 | Min3 | |||||||||||

1050 ALUMINUM COIL APPLICATION:

1050 aluminum coil has high ductility and high reflective finish. Besides, 1050 aluminum coil is non-heat treatment series is produced in extruded sections. It has excellent cold workability, braze-ability and solder-ability, and it is strengthened by cold working. However, 1050 aluminum coil has low mechanical strength compared to more significantly alloyed metals. All of these characteristics make 1050 aluminum coil well suited to chemical and electrolytic brightening but not in casting. Last but not least, moderate strength and good anodizing quality enables our products has a vast application.

RELEVANT GRADE OF 1050 ALUMINUM COIL

Relevant grade of 1050 Aluminum Coil | |

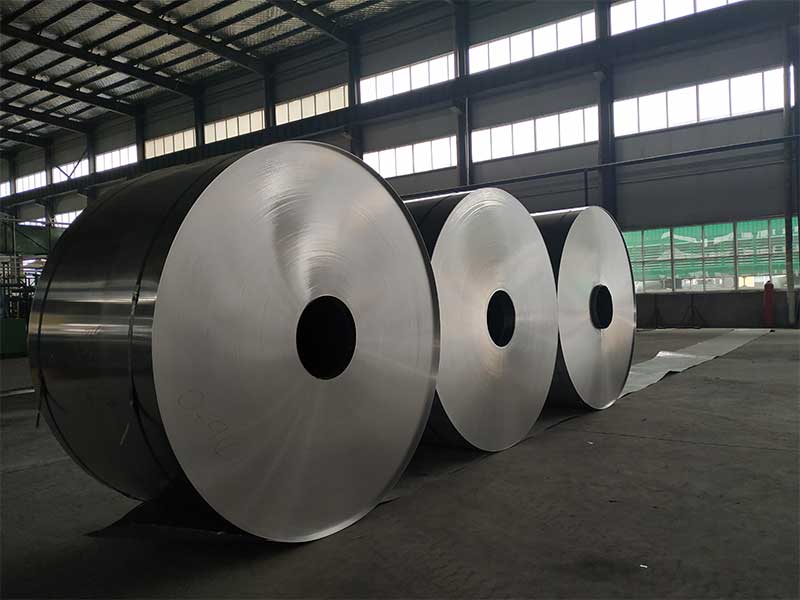

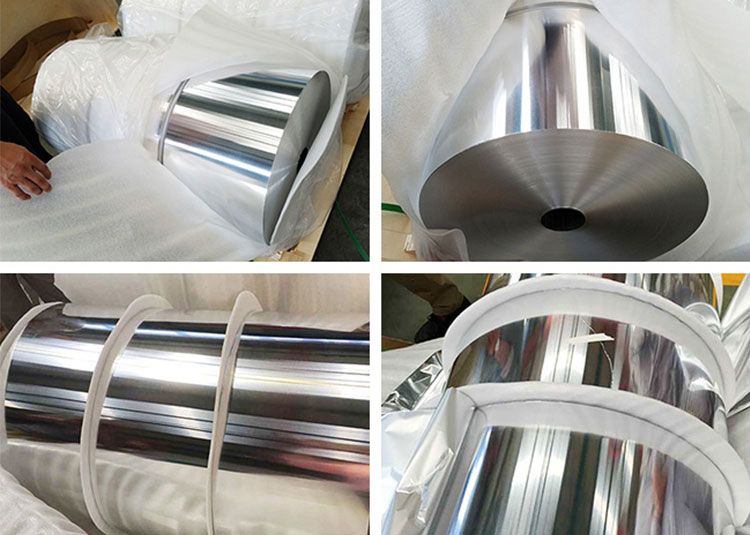

1050 ALUMINUM COIL PACKING:

1050 aluminum coil of Haomei Aluminum. meet the export standard. Plastic film and brown paper can be covered at customers’ need. What’s more, wooden case or wooden pallet is adopted to protect products from damage during the delivery. There are two kinds of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience. Generally speaking, there are 2 tons in one package, and loading 18-22 tons in 1×20′ container, and 20-24 tons in 1×40′ container.

As a China-based 1050 aluminum coil manufacturer and supplier, we at Haomei also produce aluminum foil, coated aluminum coil, aluminum plate, anodising aluminum sheet, embossed aluminum sheet, etc. For more detailed information, please continue browsing our website or feel free to contact us directly.