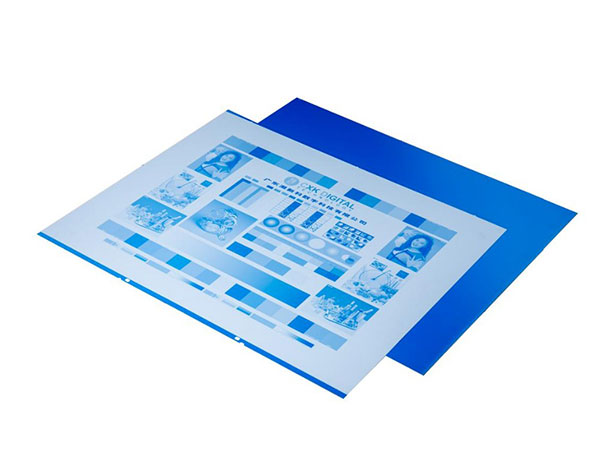

Waterless Processless Thermal Negative CTP Plate

Waterless Processless Thermal Negative CTP Plate: Revolutionizing Modern Printing

In the fast-evolving world of printing technology, the Waterless Processless Thermal Negative CTP Plate stands out as a true game-changer. Combining advanced thermal imaging with an eco-friendly, simplified workflow, this innovative plate redefines efficiency, quality, and sustainability within commercial and package printing sectors. But what exactly makes this CTP plate extraordinary? Let's explore its unique functionalities and versatile applications from a fresh vantage point.

the Technology: Why Waterless and Processless Matter

Traditional CTP (Computer-To-Plate) systems generally rely on multiple chemical processes to develop and etch the plates after imaging. This conventionamentally necessitates water, developer chemicals, gum solutions, and waste management infrastructures. In stark contrast:

- Waterless means zero water is required during plate processing. No water rollers or dampening process are involved.

- Processless indicates that the plate emerges from the CTP imaging device fully ready for press-taking, eliminating time-consuming, environmentally harmful chemical development steps.

This convergence enhances sustainability and throughput while drastically cutting costs and operator complexity.

Thermal Activation: Core Function Behind Outstanding Print Quality

At the heart of this CTP plate is the thermal negative-working coating which, when exposed to focused thermal laser light, undergoes precise physical transformations:

- A laser diode within the CTP imager reaches temperatures around 830 nm wavelength tailored for thermal sensitivity.

- The imaging layer’s polymeric compounds react by peeling selectively from the underlying aluminum base.

- The negative-working mechanism means that the areas exposed to laser light become the non-printing (receptive to wash-away) zones, leaving pristine tonal depth in the unexposed contract regions that represent artwork on the plate surface.

The thermal approach ensures high resolution, superior dot fidelity, and uniform tonal reproduction. Since the waterless plate uses a silicone rubber layer instead of common water-based disabilities for ink-water balance, it achieves steeper ink-to-area contrast with elusive minimal dot gain.

Unique Advantages Over Conventional Plates

- Eco-friendly Operation: No processing chemistry means negligible harmful effluents, dramatically reducing waste and environmental footprint.

- Fast Turnaround: Direct workflow from exposure to printing cuts prepress cycle time by up to 50%.

- Increased Press Stability: The silicone coating eliminates emulsifier variability, granting constant ink interaction that translates to sharp, consistent print runs exceeding 150,000 impressions.

- Less Operator Labor: Simplifies printer platen care and cleanup—no dampener adjustments enhance ease-of-use even for less experienced staff.

Commercial Printing

The precision and clarity delivered enhance beauty brochures, catalogs, and magazine silhouettes for premium advertising campaigns requiring detail sharpness and minute textual articulations.

Packaging

Integrating waterless thermal processless plates allows swift adaptation during flexible packaging print events, reducing material change downtime while delivering rich printed materials commands valuable shelf presence.

Newspaper and Periodicals

Despite general shift trends online, signed artworks in short newspaper cycles benefit largely from IM plate longevity in producing sustained editions with vivid headline and image legibility.

A Spin from Industry Implementation Insights

Organizations adopting the Waterless Processless Thermal Negative CTP plate notice remarkable ROI not only via cost controls (chemical-media assays involve enterprise-level charges) but through reduced maintenance Rs and enlarged machine scheduling freedom.

Moreover, its professor-sought minimal toxicity residues establish compliance relevance in markets with strict VOC and solvent discharge protocols.

Final Thoughts

Championing further ecological responsibility and coding ultimate productivity gravitates global printers toward Waterless Processless Thermal Negative CTP Plates. Offering unprecedented fusion qualities in surface science image energetics, they comfortably eliminate baseline bottlenecks traditionally ingrained in plate making while amplifying output excellence.

https://www.al-alloy.com/a/waterless-processless-thermal-negative-ctp-plate.html