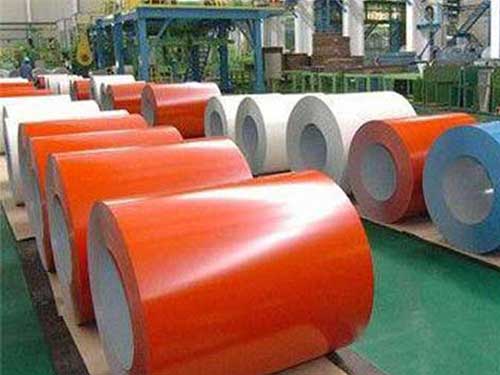

Prepainted 0.02mm-3mm Color Coated Aluminum Coil

Prepainted 0.02mm-3mm Color Coated Aluminum Coil: Enhancing Functionality and Aesthetic Versatility

In the world of building materials and industrial applications, coated aluminum coils have revolutionized how engineers and designers approach durability combined with aesthetics. Among these, the prepainted 0.02mm-3mm color coated aluminum coil stands out, offering a remarkable balance of function, finish, and flexibility.

Prepainted Color Coated Aluminum Coil

At its core, this product consists of an aluminum substrate — ranging in thickness from ultra-thin 0.02mm sheets to more robust 3mm plates — that undergoes a sophisticated coating process. Before painting, the surface is meticulously cleaned and treated, ensuring superior paint adhesion, longevity, and corrosion resistance. The color coating, often done using advanced PVDF (polyvinylidene fluoride), polyester, or fluorocarbon-based paints, imparts not only vibrant hues but also resilience to environmental factors such as UV rays, moisture, and pollutants.

Functions and Technical Features

-

Exceptional Corrosion Resistance: Thanks to multi-layer coating technology — including primers, finish coats, and back coats — the coil is shielded against oxidation and chemical damage. Even the ultra-thin 0.02mm sheets maintain integrity against rust and degradation, ideal for delicate, precision applications needing long life without sacrificing weight.

-

Enhanced Mechanical Strength with Lightness: Aluminum inherently combines strength with lightweight properties. Coated coils maintain this benefit, enabling producers to fabricate durable, enduring parts and panels without the weight penalty found in steel or other metals.

-

Precision Thickness Range & Even Coating: The availability of gauged thicknesses from 0.02mm to 3mm means manufacturers can select material tailored specifically to structural or aesthetic requirements. Uniform paint thickness control (~10-30 micrometers depending on paint system) ensures consistent color and gloss appearance without sacrificing performance.

-

Thermal Efficiency and Energy Saving: The reflective properties of coated aluminum panels can reflect infrared and visible light, reducing heat absorption. This makes them ideal for applications where energy efficiency and temperature management are vital, such as external cladding or appliances.

-

Ease of Fabrication and Formability: Whether it’s custom bending, roll forming, cutting, or punching, the prepainted aluminum coil chambers excellent formability characteristics without the risk of coating fracturing or delaminating if handled appropriately.

Applications: Bridging Engineering and Design Innovation

These coils find multifaceted applications across industries:

-

Architectural Cladding & Facades: Buildings gain visual flair with a range of color options in bold, matte, or metallic finishes. Architecturally, coated coils provide weather resistance, low maintenance, and design flexibility — ideal for curtain walls, canopies, and decorative panels.

-

Transportation Industry: Crafted elements for automotive and railway vehicles demand reduced weight and coated surfaces to withstand harsh environments and minimize upkeep.

-

Appliances & Consumer Goods: Exteriors of refrigerators, ovens, and other appliances benefit from the scratch-resistant and colorful coatings, giving products compelling looks while resisting industrial wear and tear.

-

Signage & Advertising: Brilliant, long-lasting coatings deliver attention-grabbing finishes suitable for outdoor advertising, billboards, signboards, and display kiosks, where durability and aesthetics cannot be compromised.

-

Solar Panel Frames & Components: Lightweight, weather-resistant materials enhance the viability and durability of solar pedestal mechanical hardware.

https://www.al-alloy.com/a/prepainted-002mm-3mm-color-coated-aluminum-coil.html