4x8 aluminum sheets

4x8 Aluminum Sheets: The Versatile Backbone of Modern Fabrication

When it comes to materials that combine strength, lightweight properties, and versatility, few can rival aluminum. Among its many forms, the 4x8 aluminum sheet stands out as a standard-size powerhouse in fabrication and manufacturing industries. This dimension—not just a random choice but a thoughtfully utilized size—bridges practicality and efficiency, making projects smoother and more cost-effective.

The Features that Define 4x8 Aluminum Sheets

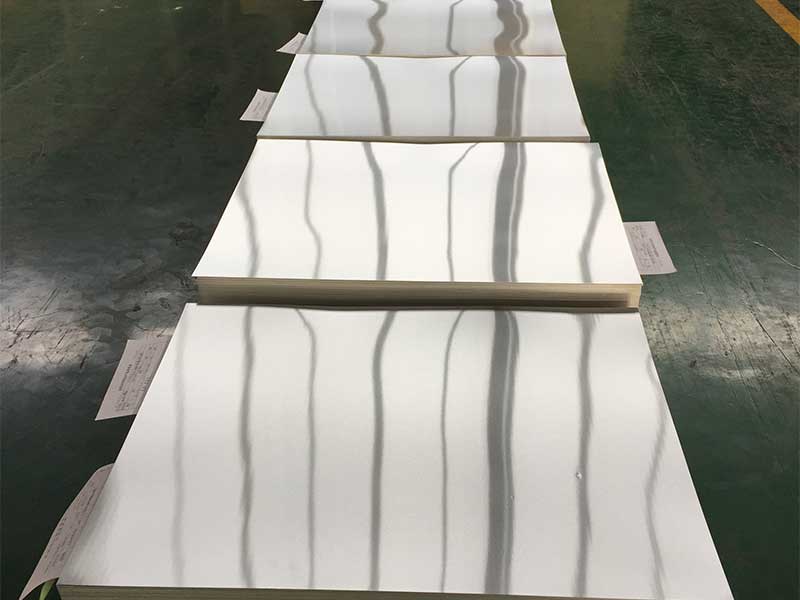

1. Standardized, Convenient Size: The 4x8 size, equivalent to 4 feet by 8 feet (48 by 96 inches), mirrors the dimensions commonly used for plywood and other sheet materials, allowing easy integration in mixed-material projects. This uniform measure ensures ease in handling, transportation, and compatibility with existing machinery like CNC routers, shears, and brakes designed around these dimensions.

2. Lightweight Yet Strong: Aluminum, inherently lighter than steel, reduces overall project weight. This is especially beneficial in industries aiming to decrease fuel consumption or structural load without compromising durability. Despite its lightness, 4x8 aluminum sheets still offer an excellent strength-to-weight ratio, lending themselves perfectly to both structural and aesthetic roles.

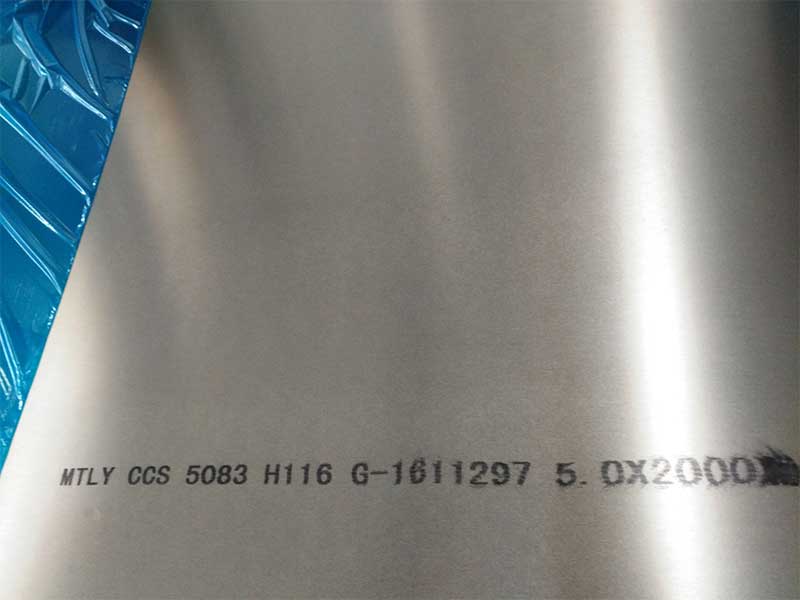

3. Excellent Corrosion Resistance: With natural oxide layering acting as a shield, aluminum sheets remain resistant to rust and corrosion. When anodized, these sheets gain enhanced durability and surface hardness. For outdoor usage or environments exposed to moisture and chemicals, 4x8 aluminum sheets provide a long-lasting option.

4. High Workability: The malleability of aluminum means these sheets can be easily cut, welded, bent, or formed into complex shapes. Their compatibility with various finishing methods (polishing, painting, powder coating) also ensures that builders and designers can achieve desired aesthetics without sacrificing performance.

Diverse Applications Powered by 4x8 Aluminum Sheets

A. Architectural and Construction Genius The 4x8 form mirrors traditional construction material sizes, making aluminium sheets a prime candidate for cladding, roofing, partition walls, and curtain walls. Their corrosion resistance means building facades stand the test of time with minimal maintenance. Also, aluminum's reflectivity offers energy efficiency benefits by deflecting solar radiation.

B. Automotive and Aerospace Craftsmanship Automobile and aircraft manufacturers leverage 4x8 aluminum sheets to design lightweight frames, panels, and casings, enhancing fuel efficiency and performance. The ease of machining standard-sized sheets accelerates prototyping and production.

C. Signage and Display Innovations Because these 4x8 panels are easy to print on and finish, they have become a staple in signage, booths, and artistic displays. They hold paint well and can be made reflective or matte, hampering wear and preserving visibility under changing environmental conditions.

D. Industrial and Agricultural Machinery Protective covers, guards, and bases receive the benefit of aluminum’s resilient but lightweight nature, ensuring equipment longevity and easier maintenance—often utilizing sheets that are cut down from standard 4x8 sizes to custom dimensions.

A Material Size That Mirrors Versatility and Efficiency

What makes 4x8 aluminum sheets truly remarkable is less about the metal itself—everyone knows aluminum is —and more about the harmony between this material’s great properties and a size that roots itself in fabrication norms. By being standardized, it simplifies inventory, reduces waste, and matches well with global supply chains. By being aluminum, it preserves strength, corrosion resistance, and ease of adaptive manufacturing.

Working with 4x8 aluminum sheets daily, I've developed a keen appreciation for their versatility, but also a healthy respect for their quirks. The seemingly simple flatness belies a subtle warpage that's always a factor. We constantly battle bowing and twisting, especially in the summer heat, which necessitates careful handling and storage. Getting a truly flat sheet ready for processing is often a mini-project in itself, involving strategic shimming and careful straightening before we can even think about cutting or stamping. It's a constant reminder that even an industrial material like aluminum has its own personality, demanding respect for its physical properties. The seemingly minor variations between batches, even from the same supplier, often necessitate adjustments to our processes.

Beyond the practical challenges, I find a certain satisfaction in the precision required to work with these sheets. The seemingly endless possibilities of what can be created from a single 4x8 sheet — from intricate signage to sturdy automotive parts — is always inspiring. Seeing a perfectly cut and finished piece, free from imperfections and ready for its intended purpose, is immensely rewarding after wrestling with its inherent recalcitrance. It’s a testament to the combination of skilled craftsmanship and robust machinery working in harmony to transform a raw material into something valuable and functional. The simple geometry of the sheet belies the complex manufacturing processes involved, both in its creation and its transformation into countless finished products.

In essence, the 4x8 aluminum sheet is a perfect marriage of tradition and innovation, offering a dependable foundation that countless industries rely on for building the future.