5083 thickness 0.5mm anodized Aluminium sheet

Aluminum might just be one of those materials that doesn't get enough love. Its magic often flies under the radar—especially when it comes to specific grades and alloys.

What Exactly Is It?

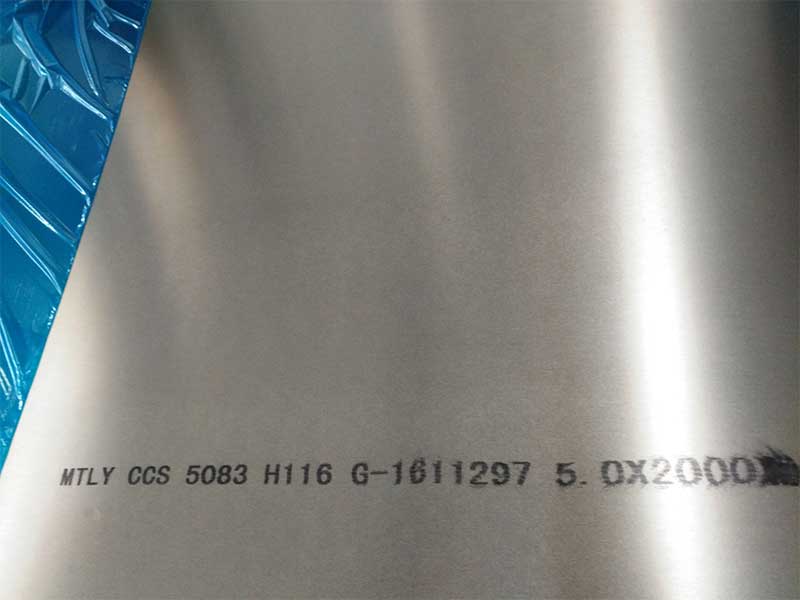

To start, aluminum sheets are flat, thin pieces of aluminum metal defined by their thickness. The 5083 grade, specifically, stands out in the aerospace and marine industries due to its exceptional strength and corrosion resistance. The 0.5mm thickness makes it downright versatile, allowing for applications where lightweight materials need to cut through the clutter of heavier, less manageable options.

Working with 5083 alloy in 0.5mm thickness, especially when anodized, presents unique challenges. Its inherent strength and weldability, desirable features of 5083, are somewhat compromised at this thin gauge. We often encounter issues with warping during the anodizing process due to the sheet's susceptibility to uneven heating and stress. Careful control of the anodizing parameters, including temperature and current density, is crucial to minimize this. Furthermore, the thinness makes handling and processing delicate; scratches and other surface imperfections are easily introduced during fabrication, impacting the final product's quality and potentially necessitating rejection. We've found that implementing specialized handling equipment and rigorous quality checks throughout the production line are essential to minimize these defects.

The anodization itself presents another layer of complexity on this thin material. While it provides excellent corrosion resistance, a too-thick anodize layer can lead to embrittlement and increased brittleness, making the sheet more prone to cracking or fracturing during bending or forming operations. Balancing corrosion protection with maintaining the sheet's mechanical properties is a constant balancing act, requiring precise control of the anodizing process and careful selection of post-treatment methods. We've had success in optimizing our process by implementing rigorous testing and adjusting parameters based on real-time feedback from thickness measurements and surface analysis to ensure a robust yet flexible final product.

But what’s the deal with the anodized bit? Anodization is actually a process that thickens the natural oxide layer on the aluminum’s surface. This isn’t just a superficial thing—it enhances durability and resistance to corrosion while giving off a sleek, shiny, aesthetic look. It's popular in a range of sizes, but cooling this beauty down to the precise thickness of 0.5mm opens up a treasure trove of possibilities.

Functionality & Applications

Okay, so we know it's lightweight. But what makes 5083 0.5mm anodized aluminum sheets function well in the real world? Here’s where the rubber meets the road—because it’s all about a symbiotic relationship between practicality and ingenuity.

-

Marine Applications: Given Aluminum 5083’s extraordinary resistance to seawater, you can find this superstar in boat hulls and shipbuilding. For those reasons— strength, weight, and durability—it’s often the go-to choice for vessels that demand lighter yet robust materials.

-

Aerospace Components: High strength-to-weight ratios mean engineers often turn to this aluminum grade for structural components in planes. The thin, 0.5mm profile means it can be extensively worked without becoming unwieldy. When weight reduction leads to fuel efficiency, aluminium gets the A+.

-

Architectural Designs: For architects aiming for a modern look, anodized aluminum sheets are a fantastic choice. They not only impart a contemporary flair but serve critical functional roles in exterior wall cladding or customizable presentation signs because they can take complex shapes with ease.

-

Industrial Applications: Equipment manufacturing—think small appliance housings or brackets—benefits significantly from its lightweight nature without sacrificing integrity. There’s a reason engineers often turn to this sheet for myriad industrial solutions.

-

Craftsmanship and Hobby Use: In the world of DIY and, craftspeople love the 5083 0.5mm anodized alum for model making and decorative items. A little sheet of shine can really enhance a project while ensuring stability and durability.

Why Choose 5083?

Choosing 5083 anodized aluminum means choosing reliability. Compared to other materials, its ability to sustain high environments far surpasses possibilities you’ll find embedded in traditional steel or plastic substitutes. While some might say metal is cold and impersonal, aluminum generations can and does prove soft, welcoming aesthetics with designs that usually come off dependent on intricate detail rather than thick industrial malaise.

Moreover, the payoff in sustainability hints at the greater good—aluminum is recyclable, making our steel-beating favorites even more earthy friendly. When care is taken to craft such alloys like the 5083, we give ourselves not only a functional object but a responsible choice for our planet.

https://www.al-alloy.com/a/5083-thickness-05mm-anodized-aluminium-sheet.html