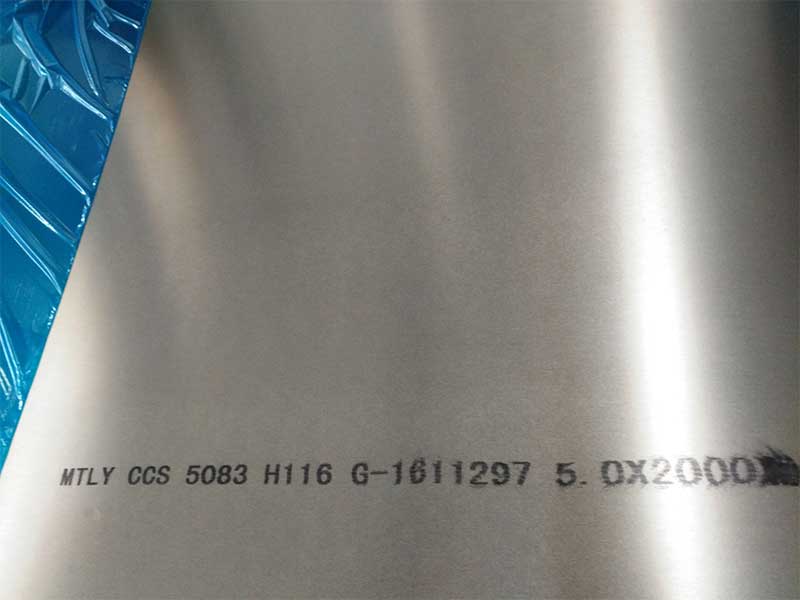

5083 aluminium plate for boat building

The Unsung Hero of Maritime Craftsmanship: 5083 Aluminium Plate in Boat Building

As boat builders and marine engineers strive for the perfect balance between performance, durability, and aesthetics, the materials they choose play a crucial role in the resulting vessel's integrity and longevity. Among a myriad of options, 5083 aluminium plate has emerged as a front-runner, often overshadowed by its more fashionable counterparts. However, when you dive into its features and applications, it's clear that 5083 aluminium plate deserves recognition as a cornerstone material in modern boatbuilding.

Working with 5083 aluminum plate in boat building presents a unique set of challenges and rewards. From a purely technical standpoint, its excellent corrosion resistance, especially in marine environments, is a huge advantage. We often see a preference for 5083 in applications requiring high strength and weldability, crucial for complex hull structures and deck components. However, the material’s inherent workability can sometimes be tricky. Getting consistent, high-quality welds requires skilled welders and precise control over parameters to avoid issues like porosity or cracking. Furthermore, the cost is a factor; while its longevity justifies the initial expense, it remains more expensive than some alternatives, demanding careful material selection to optimize both performance and budget.

Personally, I find the satisfaction in seeing a finished boat built with 5083 truly rewarding. Knowing that our plate contributes to the vessel's durability and safety, especially in harsh conditions, is immensely fulfilling. I’ve witnessed firsthand the difference between using properly prepared 5083 and substandard materials; the superior corrosion resistance is clear over time. It’s a reminder of the importance of meticulous quality control throughout the production process – from careful alloying and casting to ensuring consistently accurate plate dimensions. We’re not just producing aluminum; we're contributing to the reliability and longevity of vessels that will navigate the world's oceans.

The Features That Set 5083 Aluminium Plate Apart

1. Exceptional Corrosion Resistance One of the standout features of 5083 aluminium alloy is its exceptional corrosion resistance, particularly in marine environments. When subjected to saltwater, traditional steel and even some grades of aluminium can succumb to the dreaded rust and corrosion over time, relegating your once-sturdy vessel to a life of repairs and maintenance. In contrast, 5083 offers outstanding stability in the face of these challenges, providing long-lasting protection that gives boat builders the confidence to create vessels that can weather the storm—literally.

2. Superior Strength-to-Weight Ratio A luxury yacht requires a delicate balance of aesthetics and performance—weight distribution playing a pivotal role. The combination of exceptional strength and lightweight properties in 5083 aluminium plate makes it ideal for constructing various components—ranging from hulls to bulkheads. With less weight to carry, boats can achieve greater speeds while benefiting from improved fuel efficiency. It’s a win-win situation for boat builders and enthusiasts alike.

3. Excellent Weldability and Formability One aspect that sets 5083 apart from other aluminium alloys is its weldability. In boat building, the ability to form complex shapes and seamless joints without sacrificing structural integrity is paramount. 5083 displays excellent heat treatment characteristics, ensuring that weld integrity remains intact and that any subsequent treatments n’t counter productively affect the material.

4. Aesthetic Versatility Beyond its technical properties, 5083 aluminium can be anodized, polished, or finished to achieve stunning artistic effects, perfectly sailing the line between function and beauty. As boats are often seen not just as tools for transportation but as valuable pieces of art hovering over the water, 5083 aluminium plate serves as an ideal canvas upon which designers can express their ingenuity.

Common Applications in Boat Building

1. Hulls and Decks Given its robustness and lightness, many boat builders opt for 5083 aluminium plates when constructing hulls and decks. It can withstand the rigorous pressures of waves and storms while allowing for innovative designs and streamlined aesthetics, ultimately extending the vessel's lifespan.

2. Internal Structures Many boats utilize 5083 aluminum plate for internal structural components, including partitions, frames, and bulkheads. Its resistance to blasting and warping under extreme conditions makes it a reliable choice for charter and commercial vessels, where safety and integrity are paramount.

3. Recreational Powerboats and Yachts For recreational boat builders, 5083 aluminium plates lend themselves to a wealth of designs—everything from smooth-faced aesthetic yachts to robust fishing boats. The corrosion-resistant qualities ensure that weekend warriors don’t ruin a fishing trip due to unexpected breakdowns.

4. Transport and Carrier Vessels Within the commercial sector, profit margins often hinge on cargo capacity and speed. 5083 ensures that transport vessels achieve these goals without heavy maintenance. As demands grow for larger and faster journeying craft, 5083’s lightweight facets streamline dynamics while cutting operating costs.

https://www.al-alloy.com/a/5083-aluminium-plate-for-boat-building.html