Alloy aluminum plate 5083 h116 8011 h14 a1100 sheet

Aluminum alloy plates and sheets have been indispensable in various industries due to their inherently remarkable properties, versatile applications, and engineering capabilities. Among them, the 5083 H116, 8011 H14, and A1100 alloy sheets is know as premium aluminum products, each offering unique traits to meet a broad spectrum of needs.

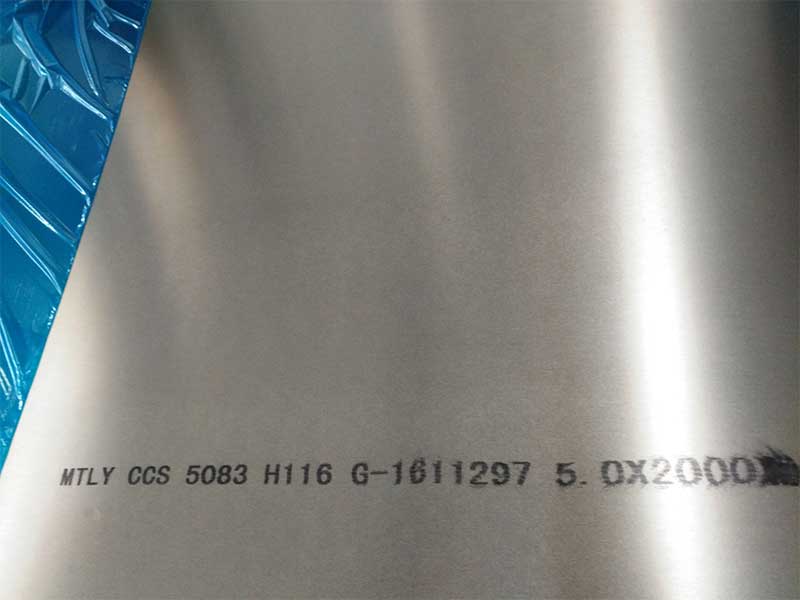

Alloy Aluminum 5083 H116: Maritime Resilience

The 5083 aluminum alloy is frequently lauded in marine applications for its unyielding strength, exceptional resistance to corrosion, and excellent welding capability. Technically, this alloy features a chemical composition mainly based on magnesium and is fortified with manganese, which scintillates not only durability but also the ability to withstand extreme environmental conditions.

Working with 5083-H116, 8011-H14, and 1100 sheet aluminum alloys daily reveals distinct processing characteristics. The 5083-H116, a high-strength magnesium alloy, presents a tougher challenge during forming operations. Its higher strength means more robust tooling is required to avoid cracking or deformation, especially in deep drawing applications. We've seen increased scrap rates on this alloy when inexperienced operators attempt aggressive bending or stamping without proper lubrication and tooling design. Conversely, 8011-H14, a softer aluminum alloy, is surprisingly forgiving, ideal for applications requiring deep drawing or complex shapes. Its excellent formability reduces tooling wear and the chance of defects, yet its lower strength limits its suitability for high-stress components. Careful consideration of the intended application is paramount in choosing between these two.

The 1100 sheet, a pure aluminum alloy, sits at the other end of the spectrum. Its exceptional ductility and corrosion resistance make it a favorite for chemical processing equipment and decorative applications where ease of forming and weldability are prioritized. However, its low strength necessitates careful consideration of its structural limitations. A common mistake is underestimating its susceptibility to deformation under load, especially in larger sheets. We've seen instances where seemingly minor imperfections in handling 1100 sheet resulted in significant warping or buckling. Therefore,

Characteristics:

- Corrosion Resistance: Essential in shipbuilding and coastal constructions.

- Yield Strength: Offers a synergistic approach to durability, with yield strength values significantly above 220 MPa.

- Weldability: 5083 displays excellent weldability that allows robust fabrication techniques often required in constructing hulls.

Applications:

- Marine Applications: Perfect for hulls, decks, and superstructures in vessel construction.

- Transportation: Favors chassis components of vehicles that require high strength-to-weight ratios.

- Industrial Applications: Frequently employed in cryogenic tanks and pressure vessels.

Alloy 8011 H14: Engaging Versatility

Aluminum alloy 8011 H14 represents imagination in its simplest form, creating functional interactivity with modest thicknesses often comparable only to heavier materials. This designation emphasizes the alloy’s mix of aluminum along with trace impurities, focusing primarily on cans, flexible packaging, and housing transistors especially fitting for applications requiring a balance of flexibility and rigidity.

Characteristics:

- Formability and Flexibility: Features superior liability for bends; useful in intricate designs.

- Surface Finish: Known for having a high-quality surface, delivering aesthetic properties desirable for consumer applications.

- thermal conductivity: Aesthetic and behavior impacting attributes notably extend into electronics applications.

Applications:

- Food Packaging: Used extensively from aluminum foils to household food containers, it excels in barrier properties keeping products fresh.

- Construction Materials: Finding its mark on roofing applications and other panels requiring a lightweight yet tough alternative.

Alloy A1100: beguiling, Lite Elegance

When weight matters, the lightweight elegance of A1100 should be your focal point. Known for its wrought state with extensive forming possibilities, A1100 aluminum plates often serve as an aerospace material that does not compromise the essentials of durability and strength.

Characteristics:

- Excellent Corrosion Resistance: Comprising pure aluminum alloy helps prevent oxide film weakening.

- Good Fabrication and exceeding Minimizing capabilities: Allows detailed craftsmanship without compromising structure.

- Ductility and Throws Trade-offs Transition ripping shaping satisfies both craftsmanship and structural integrity.

Applications:

- Food and Chemical Handling: Malik0ng receptacles such as tanks, containers holding various food processing revolutions.

- Heat Ex exchangers: Used within cooling and heating offerings given itsthurwork nets498core duty usage moderate distance and durability extended endurance without embracing consequences.

The Touch Points of Design Innovation and Optimal Performance

The aluminum sheet 5083 H116, 8011 H14, and A1100 plates don’t simply fulfill demand; they synergistically redefine it. With applications ranging in fields from aerospace to big aquatics, their design mentality demonstrates how raw materials can propel industries to new heights.

When designers understand the nuances becoming dissect specific needs such as weld strength, pliable films retaining risk factors such supporting elements accrual, they harness intrinsic values born from technical file everywhere thousands of forms meant generate sustainance directed craftsmanship. Ultimately, champions of imagination become reliant perched strength translating sculpts metals competencies navigating an increasingly demanding market crowned Metals forging Empires.

https://www.al-alloy.com/a/alloy-aluminum-plate-5083-h116-8011-h14-a1100-sheet.html