5083 H112 10mm Aluminum Plate

In the realm of materials science, few substances can compare to aluminum, the lightweight yet robust metal that has transformed industries since its advent. Within this expansive world, one specific variant stands out for its unique balance of strength, corrosion resistance, and versatility: the 5083 H112 aluminum plate in a 10mm thickness. While many materials might fit particular roles in construction or manufacturing, this aluminum plate takes those responsibilities to the next level.

The Strength of the 5083 Alloy

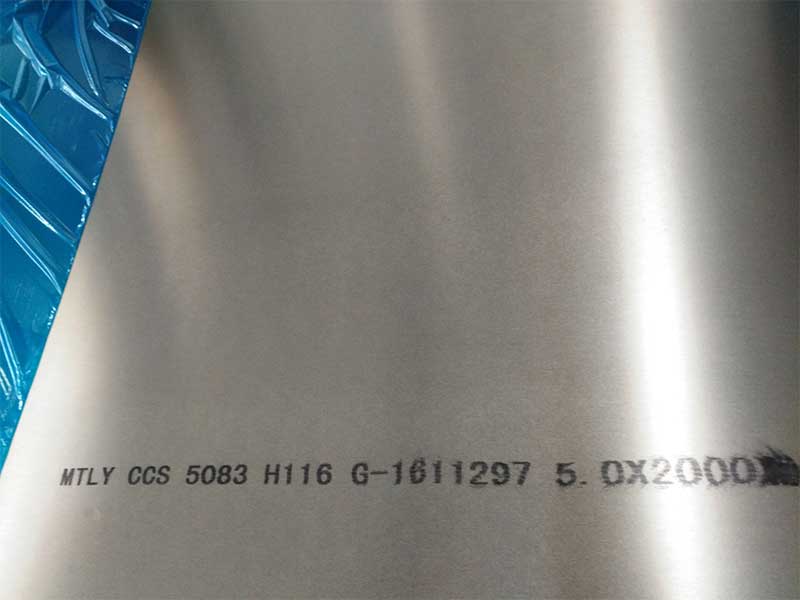

When we talk about the 5083 alloy — filled with around 4.0% magnesium and 0.4% manganese — it is essential to first understand its properties. The H112 temper specifically relates to its mechanical properties post-processing, designed to fortify the base characteristics of this robust aluminum product. This temper provides a level of tensile strength that exceeds expectations, making it resilient for demanding applications.

The 5083 H112 10mm aluminum plate isn't just another piece of metal; it's a carefully engineered solution, a testament to the sophisticated interplay between material science and application-specific requirements. Its unique character lies not just in its composition (a magnesium-based alloy offering excellent corrosion resistance) or its temper (H112, signifying a strain-hardened condition balancing strength and formability), but in the synergistic effect of these properties at a substantial 10mm thickness.

Many overlook the significance of the 10mm thickness. This isn't simply a matter of scaling up a thinner plate. At this gauge, the 5083 H112 demonstrates a distinct advantage in applications demanding high stiffness and impact resistance. While thinner gauges might suffice for lighter-duty applications, the 10mm plate provides a crucial level of structural integrity, minimizing deflection and ensuring long-term performance under considerable stress. This is critical in environments prone to vibration or dynamic loading, a factor often underestimated in design specifications.

Furthermore, the H112 temper offers a sweet spot. It's not as hard as some higher-numbered tempers, making it more readily formable – a crucial aspect for complex geometries. This allows for cost-effective fabrication, a significant advantage over using a harder temper that would necessitate more expensive machining or forming processes. The inherent strength, however,

Imagine building a marine vessel that must surmount the relentless forces of winds and waves. The integrity of the framework is paramount. Here, the 5083 H112 10mm aluminum plate shines due to its unbeatable strength-to-weight ratio allowing engineers and builders to achieve greater fuel efficiency while ensuring durability.

Corrosion Resistance: An Urban Sea Change

Perhaps most appealing about the 5083 aluminum plate is its exceptional resistance to corrosion — a vital quality for any material facing the unpredictable nature of marine environments. Often involved in projects such as shipbuilding and offshore structures, 5083 takes the vibrancy of seawater and transforms it into a non-negotiable safeguard. Especially relevant in a world where environmental conditions can jeopardize structural integrity, this alloy can weather the storm, figuratively and literally.

When employed in the manufacturing of hulls, superstructures, and various other marine applications, the inherent safety of 5083 H112 becomes evident. Vessels crafted from this alloy stay rigorous against operating pressures while reducing maintenance costs and prolonging lifespans, another notable underground advantage.

The Versatile Landscape of Aluminum Applications

But the potential of the 5083 H112 10mm plate is not confined to marine applications. In the industrial sphere, its demand is escalating. Use cases range from automotive parts to building constructions. For instance, some may argue that the automotive sector inspires innovation in lightweight components designed for fuel efficiency, such as engine mounts or structural elements in vehicles. Here too, the strength and reduced weight of 5083 provide a tactical advantage.

Furthermore, architects embrace this alloy for its intrinsic aesthetic. A smooth surface finish coupled with exceptional resilience leads to designs that are not only functional but alluring. For contemporary buildings adopting vast glass facades or avant-garde angles, aluminum fixtures made of 5083 deliver structural soundness, translating into architectural creativity.

An Eager Dimension

In engaging with the 5083 H112 10mm aluminum plate, one isn’t merely working with a hunk of metal; it embodies a careful balancing act of science and application. Suppliers and fabricators developing these materials play an essential role, serving as the touchpoint between innovation and reliability. Skilled craftsmanship is to exploiting its full potential, with professionals needing to understand not only technical specifications but also practical applications to leverage its advantages fully.

https://www.al-alloy.com/a/5083-h112-10mm-aluminum-plate.html