5083 5251 5052 5000 Series Aluminum Sheet

Innovating with Aluminum: the 5083, 5251, 5052, and 5000 Series Sheets

In the world of metallurgy and fabrication, aluminum perennial hookups weave into innumerable engineered applications. At the forefront of this innovation are the 5083, 5251, 5052, and 5000 series aluminum sheets, which is know for their mechanical properties, corrosion resistance, and versatility.

Working with 5083, 5251, 5052, and other 5000 series aluminum sheets daily reveals distinct processing nuances. 5083, with its higher magnesium content, boasts exceptional strength and weldability, making it a go-to for demanding applications like marine and transportation. However, its higher strength also means it requires more attention during forming operations; aggressive bending can lead to cracking if not handled carefully, necessitating precise tooling and slower speeds. Conversely, 5052 offers superior corrosion resistance, particularly in marine environments, but sacrifices some strength compared to 5083. We often see 5052 used in chemical processing equipment where corrosion is a paramount concern. these trade-offs – strength versus corrosion resistance – is critical for selecting the right alloy for a specific application.

The 5000 series as a whole presents challenges related to surface finish and work hardening. While generally easy to machine, improper tooling or excessive passes can lead to surface imperfections. Furthermore, the work hardening rate varies across alloys. 5251, for example, exhibits a moderate work hardening rate, requiring careful monitoring during forming to prevent premature failure. We've learned that investing in regular tooling maintenance and operator training on specific alloy characteristics is vital for maintaining consistent product quality and minimizing scrap. Ultimately, successful processing hinges on a deep of each alloy's unique mechanical

A Closer Look at the 5000 Series Aluminum

The 5000 series derivatives of aluminum—5083, 5251, and 5052—are often acknowledged for their potency and adaptability. As magnesium is the primary alloying element, these sheets boast excellent corrosion resistance and weldability. But here's where the flair lies: each alloy comprises distinctive strengths enabling them to rise above conventional materials.

- 5083 Aluminum Sheets – Durability Under Pressure

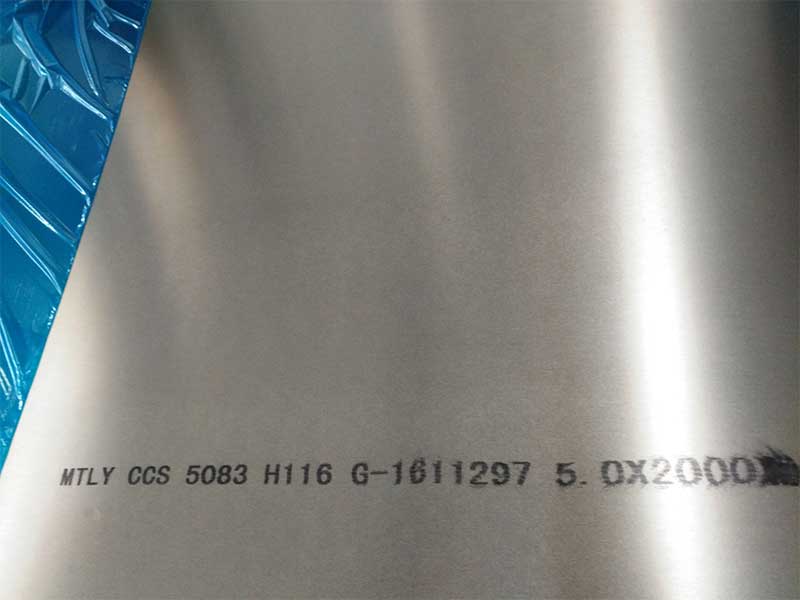

The 5083 aluminum sheet is renown for its robust performance in challenging marine environments. Its resistance to seawater corrosion makes it gain traction in shipbuilding, where every ounce of durability matters. In an engineering project, where additives may weaken integrity, the 5083 shines brightly by offering high strength and weldability. Combining these features allows manufacturers in the defense sector to explore innovative designs and enhance safety.

- 5251 Aluminum Sheets – The Roll of Flexibility

The 5251 aluminum sheet embodies flexibility paired with strength—it camps comfortably in scenarios that involve bending and shaping. For automotive applications, the aluminum bodywork receives a powerful ally in 5251 sheets, given their capacity to mold without losing structural integrity. They also deliver excellent resilience, making them ideal in the manufacture of pressured gas containers and similar applications. Where many materials crack under stress, the 5251 offers longevity and safety assurance.

- 5052 Aluminum Sheets – Power in Applying Lightweight Strength

The 5052 aluminum sheets represent superior formability and structural sturdiness—qualities quintessential for components in transportation, shipbuilding, and even food packaging sectors. As architects and designers choose materials that maintain integrity while minimizing weight, 5052 aluminum sheets present a commendable solution. Their remarkable workability allows engineers bargaining traits from softness: excellent finishing capabilities, thus enhancing the aesthetic potentials greatly.

- Distinct None Yet Inter-changeable

One of the unique angles to frame each alloy’s use springs from imposing their overlap. Even though 5083, 5251, and 5052 have distinct specialties, they also serve interchangeable roles in myriad applications. Whether substituting one another in production lines or combining materials for specific unique functions, architectural designs refreshingly witness the fluidity between these alloys. While this interchangeability might pose problems concerning mechanical performance, manufacturers often thrive on leveraging these differences to minimize costs without knocking down quality.

Real-World Implications and the Path Ahead

With increasing global demands aligning to heightened environmental protocols, industries are gradually diverting to aluminum solutions due to their recyclable characteristics without compromise on strength. Large-scale construction, automotive, marine building, and HVAC systems indulge happily with these metabolic advancements.

Looking ahead, the growth portfolio for the 5083, 5251, and 5052 aluminum sheets appears fertile. The burgeoning electric vehicle market and advancements in renewable energy exemplify how established metals evolve in unison with innovative technologies.

As we embrace the digital prism guiding engineers and fabricators of evolving industries, the whimsy behind these aluminum sheets caters flexibility to the production landscape that turns attributes once tradable into opportunities for enrichment.

https://www.al-alloy.com/a/5083-5251-5052-5000-series-aluminum-sheet.html