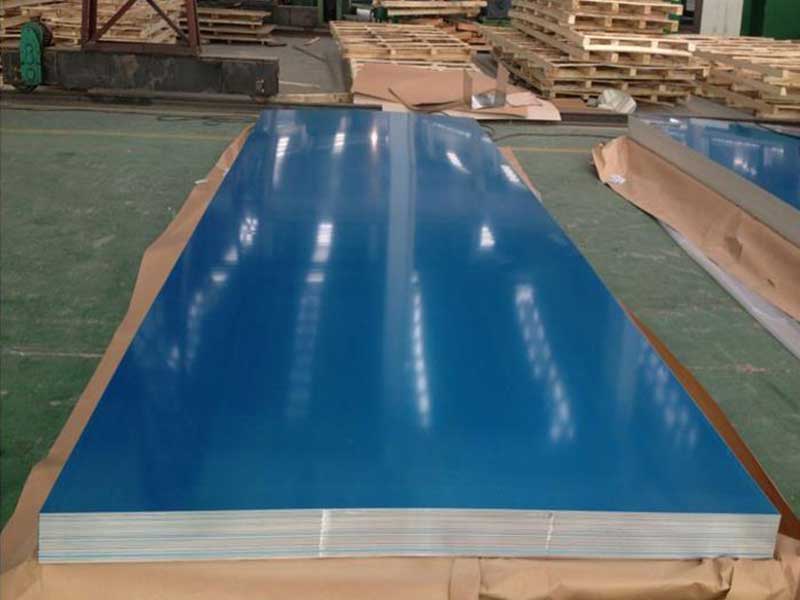

1050 H24 Aluminium Plate for Building

The Versatility of 1050 H24 Aluminum Plate in Building Applications

When it comes to building and construction materials, the choices available to architects and builders can be overwhelming. However, the increasing demand for lightweight yet durable materials has led many to explore the myriad applications of the 1050 H24 aluminum plate. Renowned for its remarkable physical properties and usability, this aluminum alloy has secured a coveted place in modern architecture and infrastructure.

1050 H24 aluminum plate, with its exceptional formability and corrosion resistance, is a popular choice for building applications, particularly in cladding and roofing. However, its relatively low strength compared to other aluminum alloys means careful consideration of structural design is crucial. In my experience, we often see issues stemming from inadequate support structures for larger panels, leading to sagging or buckling over time, especially in areas with significant wind load or thermal expansion. Proper installation techniques, including the use of appropriate fasteners and expansion joints, are paramount to prevent these problems and ensure the longevity of the building façade. We've also had instances where improper surface preparation before painting or coating led to premature corrosion, highlighting the importance of meticulous surface cleaning and pre-treatment.

Beyond the purely structural considerations, the inherent workability of 1050 H24 can be both a benefit and a challenge. Its softness makes it easier to fabricate, reducing manufacturing costs and allowing for intricate designs. However, this same softness makes it susceptible to scratching and denting during handling and transportation. We've implemented stricter quality control measures at our facility, including specialized packaging and improved handling techniques, to minimize damage. Moreover, educating construction crews about the material's properties and the importance of careful handling during installation is crucial to achieving a high-quality, long-lasting finished product. Investing in thorough training and providing clear installation guidelines are to maximizing the lifespan and aesthetic appeal of 10

Unique Characteristics of 1050 H24 Aluminum Plate

The 1050 H24 aluminum plate belongs to the 1xxx series of aluminum alloys with a minimum of 99.5% aluminum content. This purity confers several technical advantages:

-

Excellent Corrosion Resistance: One of the standout features of the 1050 H24 aluminum plate is its exceptional resistance to corrosion. This makes it an ideal choice for building exteriors exposed to various environmental challenges, including moisture, pollutants, and UV rays.

-

Light Weight But Sturdy: Weighing only roughly one-third of steel, the weight advantage of aluminum extends to a reduced load on structural supports. Incorporating 1050 H24 aluminum in building designs can ultimately lead to lower material costs and improved building performance while facilitating ease of installation.

-

Workability: This aluminum plate attains its H24 temper through a process of strain hardening followed by low-temperature annealing. This configuration provides optimal formability, making it easy to cut, weld, and customize to specific design requirements. It’s not merely that the material is lightweight; it’s also manageable, which increases the efficiency of construction projects.

-

Thermal and Electrical Conductivity: With decent thermal and electrical conductivity, 1050 H24 aluminum is beneficial in applications requiring heat exchange efficiency or an electrical conduit, a feature that often necessitates consideration in multifaceted building systems.

Applications of 1050 H24 Aluminum Plate

-

Roofing and Cladding: The corrosion resistance and light weight of 1050 H24 make it an excellent candidate for roofing materials and cladding applications. Builders can take advantage of its reflective surface to aid in thermal insulation, potentially decreasing energy costs in climate-controlled environments.

-

Partitions and Panels: The ease of customization allows for use in partition walls and decorative panels within interiors, creating aesthetic space dividers that maintain structural integrity but do not overload building frameworks.

-

Interior Fixtures: This aluminum alloy can be manufactured into a variety of shapes, making it ideal for custom fixtures in facilities like kitchens, hospitals, or any high-hygiene settings where infection control is paramount due to its cleanliness and non-toxicity.

-

Signage and Architectural Elements: The aesthetic versatility of 1050 H24 aluminum plates lends itself well to signage, façades, and other architectural elements. Its ability to maintain a clean and sleek appearance over time while being easy to manipulate encourages innovative designs.

Wink of Innovation: Sustainability Considerations

A distinctive aspect of the growing interest in 1050 H24 aluminum plates is their recyclability. Aluminum can be reused indefinitely without substantial loss of strength, presenting a compelling case for environmentally conscious projects. When utilized sustainably, 1050 H24 can reduce the carbon footprint of construction projects significantly.

https://www.al-alloy.com/a/1050-h24-aluminium-plate-for-building.html