Colored Mirror Aluminum Sheet

Unveiling the Magic of Colored Mirror Aluminum Sheets: A Synthesis of Functionality and Aesthetics

The unique attributes of colored mirror aluminum sheets make them an exceptional choice for a wide gamut of applications. Injecting vibrancy and elegance while offering unrivaled practicality, these sheets serve various industries from architecture to manufacturing.

Aesthetics Meets Performance

Reflecting color on a durable substrate like aluminum adds a dimension of contemporary design while retaining structural integrity. The captivating finish is achieved through an advanced coating process that not only embellishes but ensures long-lasting durability. The surface finish properties help in captivating attention while brightening spaces, all while providing pivotal performance features such as corrosion resistance.

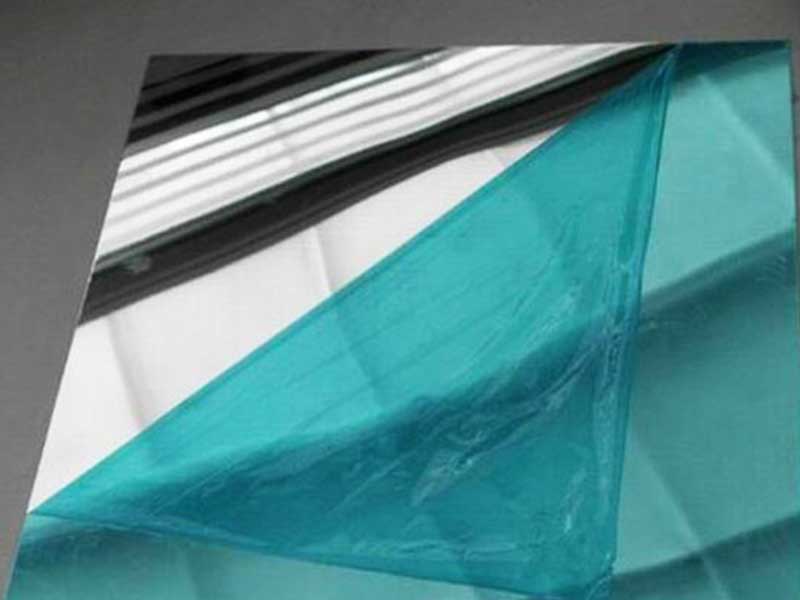

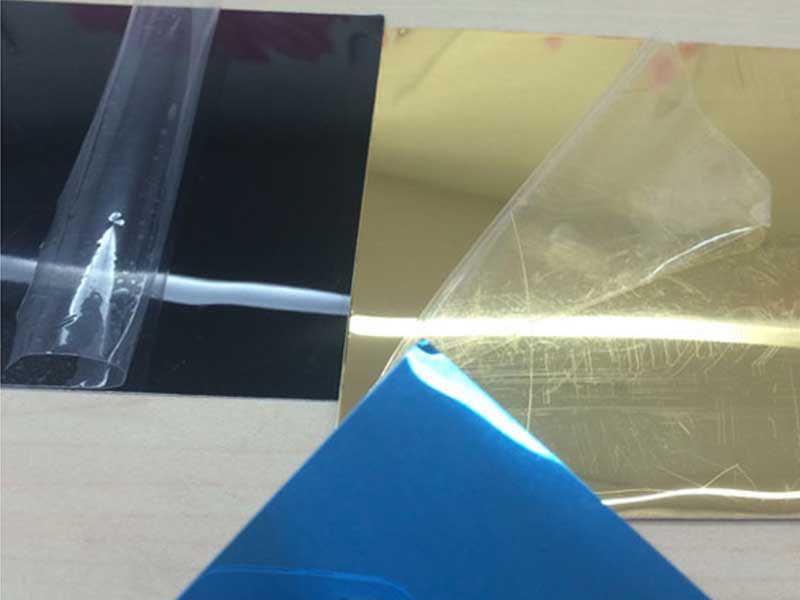

Colored mirror aluminum sheet presents unique challenges compared to standard mirror finishes. The color deposition process, whether through anodizing, PVD coating, or paint, significantly impacts the final reflectivity and durability. For example, while anodizing offers good corrosion resistance and a variety of colors, it can slightly reduce the initial reflectivity compared to a pure aluminum mirror. PVD coatings, on the other hand, boast superior durability and vibrant colors but are more expensive and require precise control of the deposition process to avoid inconsistencies in color and reflectivity across the sheet. We've seen instances where improper curing of paint-based colored mirrors leads to premature peeling or discoloration, highlighting the importance of rigorous quality control at each stage of production. the trade-offs between cost, reflectivity, color accuracy, and longevity is crucial for selecting the appropriate coating method for a specific application.

Beyond the manufacturing process, the application itself dictates the desired properties. A colored mirror used in a high-humidity environment, like a bathroom, necessitates superior corrosion resistance, likely favoring anodizing or a robust PVD coating. Conversely, a decorative application might prioritize vibrant color over ultimate durability, potentially making a painted finish acceptable despite its shorter lifespan. We've learned that thorough consultation with the client about intended use and environmental conditions is critical. This allows us to recommend the optimal coloring method and ultimately deliver a product that meets their expectations and performs reliably in its intended setting. Mismatched expectations in this area lead to significant

Technical Composition of Colored Mirror Aluminum Sheets

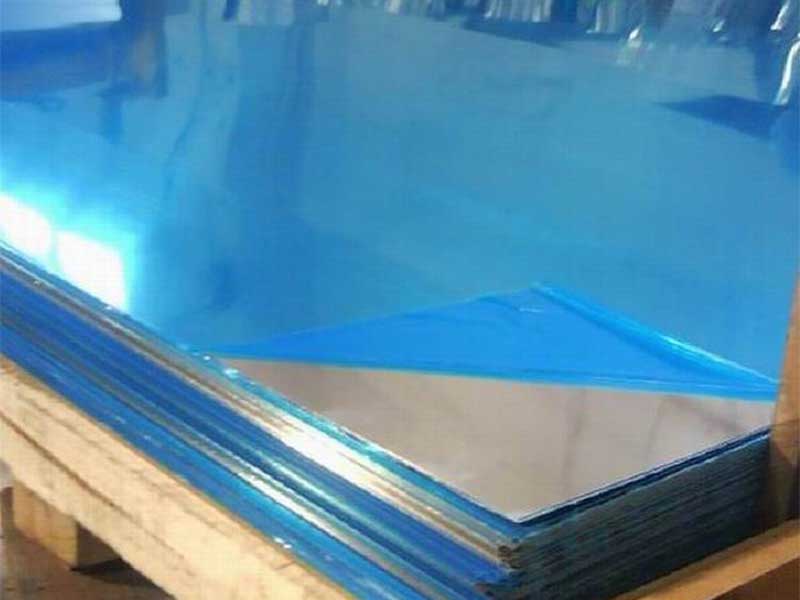

Colored mirror aluminum sheets are created from a segmented process involving:

-

Base Material: High-grade aluminum, paramount for strength to weight ratio. Generally, grades like 1050 and 1060 are utilized for their excellent workability and decorative properties.

-

Coating: A reflective polymeric or metallic paint is meticulously applied to develop colors, creating a pleasing mirror finish. It's commonly procured through technologies such as PVD (Physical Vapor Deposition) which allows a uniform and even distribution, enhancing the reflective properties of the aluminum.

-

Finish Options: Industry-standard finish types include high gloss, matte, and anodized finishes. High gloss reflects an elegant sheen, vital for display applications, while textured matte approaches possess qualities of subtlety, adding sophistication while reducing glare.

Functionality and Applications

Architectural Delight

The application of colored mirror aluminum sheets gains predominant traction in architectural projects. They are commonplace in:

-

Interior Design: Rooms adorned with colored mirror aluminum can give a feeling of spaciousness. Elegant aesthetics combined with reflective qualities can lighten up spaces through strategic placement.

-

Exterior Cladding & Facades: Buildings incorporate colored sheets to create eye-catching metallic skins that captivate onlookers while reflecting daily changes in natural lighting widely seen in modern urban designs.

Display Solutions

Retail environments leverage colored mirror aluminum sheets for engaging and dramatic displays:

-

Signage & Branding: One can easily spot reflective surfaces conjuring dynamism and belief in one’s brand—it becomes an eye-catcher invariably resulting in an influx of patronage based on appeal.

-

Exhibit Displays: Museums and trade shows utilize colorful sheets to create sculptures or backdrop environments that draw people in. Strength matched with aesthetic instincts places colored colored aluminum sheets as a cabinetry design standard.

Creative Arts and Industrial Uses

Colored mirror aluminum sheets even find their foothold in domains like automotive or consumer product designs where visuals play a crucial role. Their potential doesn’t end at mere appearance but contributes significantly toward weight reduction strategies resulting in enhanced scale efficiencies without compromising durability—opening avenues for:

- Equipment Housing: In tech environments, their lightweight yet superior structural attributes underpin functionality, best showcased in custom projects where utility can merge with innovative design elements.

https://www.al-alloy.com/a/colored-mirror-aluminum-sheet.html