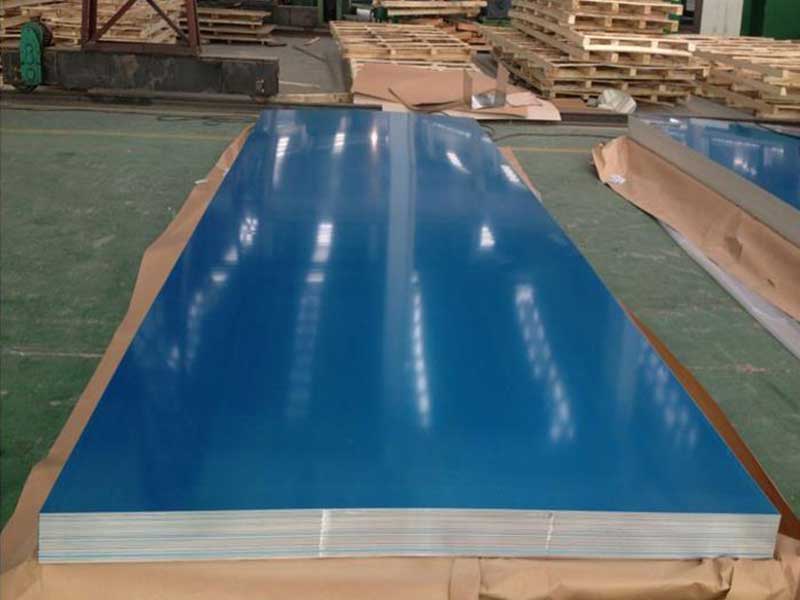

Anodized aluminum sheet Mill Finish 1050 1100 3003 5052

Anodized aluminum sheets have become indispensable materials across various industries thanks to their unique blend of durability, aesthetic appeal, and lightweight characteristics.

What is Anodized Aluminum?

Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum surfaces. This intervention significantly improves corrosion resistance, surface hardness, and aesthetic qualities. Mill finish aluminum sheets retain the natural textures and appearances, offering an industrial look while being ready for further processing.

The Features of Anodized Aluminum Sheets

-

Corrosion Resistance: One of the standout features of anodized aluminum sheets is their exceptional resistance to corrosion. This characteristic makes them suitable for various environments, especially those that expose materials to moisture and chemical interactions.

-

Durability: Anodized aluminum has a hard exterior, which means it can withstand wear and tear. The robustness of Mill Finish 1050, 1100, 3003, and 5052 variants ensures that they can be utilized in demanding applications without degrading quickly.

-

Lightweight: Aluminum is inherently lightweight compared to other metals, making these sheets easy to handle and transport. Mill Finish variants, when anodized, maintain this low weight feature while providing enhanced durability.

-

Aesthetic Options: The anodizing process allows for a variety of finishes, including satin, matte, and glossy. This level of customization makes it easy to integrate these sheets into design-oriented applications where appearance is just as essential as performance.

-

Versatility: Different grades of aluminum offer specific advantages. For instance, while 1050 and 1100 are ideal for applications that require excellent workability and corrosion resistance, 3003 provides enhanced strength and machinability, while 5052 sheets are favored for their incredible formability and weldability.

Applications of Anodized Aluminum Sheets

Anodized aluminum sheets — particularly Mill Finish variants 1050, 1100, 3003, and 5052 — find use in a vast array of industries:

-

Architecture and Construction: Ideal for facades, roofing, and reinforcement in construction projects, these sheets offer aesthetic appeal and durability that are essential for outdoor applications.

-

Automobiles: The lightweight and strong specifications of aluminum sheets make them a preferred choice in car manufacturing, especially in body structures and aesthetic trims.

-

Consumer Goods: From appliances to electronic housings, anodized aluminum sheets are prevalent in products designed for everyday use, providing both aesthetic flexibility and durability.

-

Aerospace: The aerospace industry relies heavily on anodized aluminum sheets due to their weight-to-strength ratio. operational components utilize the 5052 variety for its remarkable toughness without adding unnecessary weight.

-

Marine Applications: The corrosion resistance of anodized aluminum is a boon for marine vessels. Using 3003 and 5052 variants minimizes maintenance costs, extending the lifespan of components exposed to harsh marine environments.

https://www.al-alloy.com/a/anodized-aluminum-sheet-mill-finish-1050-1100-3003-5052.html