3A21 5005 5052 5083 2mm 2.5mm aluminum sheet

When it comes to aluminum sheets, choice of alloy and thickness play pivotal roles in determining the mechanical properties, aesthetic appeal, and applicability in various domains.

Alloy Characteristics and Features

3A21 Aluminum Sheet

As an alloy that belongs to the 3000 series, 3A21 aluminum offers an balance of strength and workability. Characterized by great corrosion resistance and good weldability, 3A21 aluminum is particularly notable for its lightweight nature combined with considerable toughness. The 2mm and 2.5mm sheets serve as ideal components for projects where moderate strength and weight optimization are critical, such as in manufacturing refrigerator panels, ductwork, and awning frames.

5005 Aluminum Sheet

Alloy 5005 is primarily pursued for its spectacular aesthetic appeal owing to the application of anodizing processes. The sheets' ability to produce vibrant and durable colors not only provides functionality but also enhances products' appearances, perfect for decorative uses. In 2mm and 2.5mm gauges, this alloy excels commercially in the fabrication of signage, architecture embellishments, and interior design elements where aesthetics do not undermine performance.

5052 Aluminum Sheet

Finding common usages in marine environments, the 5052 alloy stands out due to its stellar resistance to salty or corrosive waters alongside enhanced weldability. The matter-of-fact ductility translates well into 2mm and 2.5mm sheets swiftly molded into shapes required in manufacturing marine vessels, fuel tanks, and pressure vessels. Not only does it benefit aquatic applications, but its flexibility and resilience also cater exceptionally well to users in food and beverage industries, fabricating components that can endure increased stress during operation.

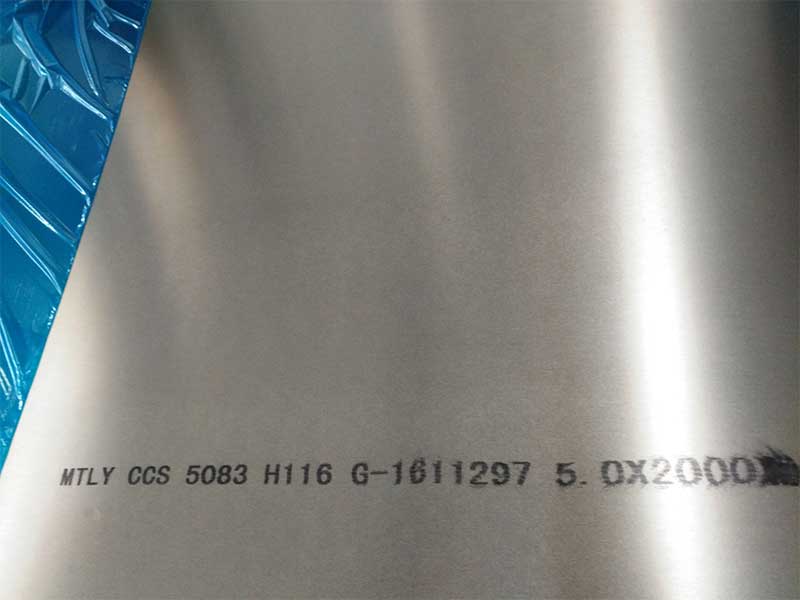

5083 Aluminum Sheet

Lastly, but equally , is the strength and robustness of alloy 5083. Considered one of the strongest effectively processed aluminum, the 5083 sheets boast superior performances in extreme conditions. The hallmark 2mm and 2.5mm thicknesses afford these plates to build structures within demanding environments—think aerospace and shipbuilding industries where uncompromising integrity is a non-negotiable.

Unique Applications Beyond the Obvious

Breaking further into the applications, a striking feature of these alloys in specific gauges is their manageable nature that nurtures both versatility and elegance—akin to multidimensional puzzle pieces capable of adapting to geometric transformations.

-

Heavy-Duty Cleanrooms: The 5083 alloy's superior corrosion resistance easily overcomes sanitation floors and surfaces tasked with housing cleanroom environments. Here stringent safety measures must coexist with abating microbiological environments.

-

Artistic Installations: 5005 undoubtedly masterworks in artistic metal displays; its ease of color manipulation interlocks strongly into architecture and modern interior designs resonating a season-free allure.

-

Lightweight transportation: Both 5052 and 3A21 provide aids machinery schools to develop fleet solutions rapidly unfurl through efficiency listening boldly through materials custom to vehicle frames—pragmatic and progressive ergonometrics.

Technical Dimensions Simplified

technical details does not always require matering jargon. The typical usage of sheets in 2mm and 2.5mm thickness allows for ease of portion sizing applications. They can be purchased in bigger volumes—tailored cut-sheets yielding ornately cutting per structural challenges and desired applications while shouldering issues of precision befitting individuals preferring iterative prototypes before final delivery configuration.

https://www.al-alloy.com/a/3a21-5005-5052-5083-2mm-25mm-aluminum-sheet.html