Anodized Aluminum Sheet AA1200, A1060, A1050

Anodized Aluminum Sheet AA1200, A1060, A1050: Features and Applications

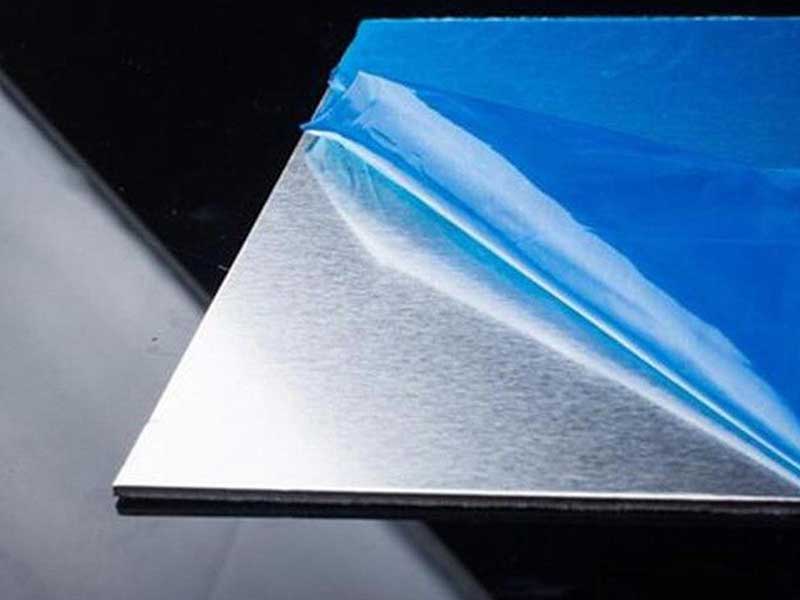

Anodized aluminum sheets have become increasingly popular in various industries due to their enhanced properties and aesthetic appeal. Among the most commonly used alloys in anodized aluminum sheets are AA1200, A1060, and A1050. Each alloy offers unique characteristics tailored for specific applications, making them indispensable in the modern manufacturing landscape.

Features of Anodized Aluminum Sheets

-

Corrosion Resistance: One of the primary reasons for anodizing aluminum is its remarkable corrosion resistance. The anodizing process creates a thick layer of oxidized aluminum on the surface, which protects it against environmental factors that can lead to wear and rust. This property is particularly advantageous in outdoor applications or in industries such as automotive, architecture, and marine.

-

Durability and Strength: Anodized aluminum sheets retain the inherent strength of aluminum while enhancing its surface hardness. The anodization process increases hardness significantly, offering resistance to scratches and mechanical trauma. Aluminum alloys like AA1200, A1060, and A1050 are capable of withstanding various physical stresses, making them ideal for components that require long-term durability.

-

Lightweight Nature: Aluminum is renowned for being light compared to other metals, which reduces transportation and material handling costs. This property is particularly crucial in manufacturing applications such as aerospace and automotive industries, where weight reduction can significantly improve efficiency and performance.

-

Aesthetic Appeal: Anodized surfaces can be dyed in various colors, enabling manufacturers to achieve specific aesthetic treatments. The ability to produce an aluminum sheet that meets design specifications while retaining a durable finish is essential for decorative applications in architectural facades, signage, and household goods.

Anodized Aluminum Alloys: AA1200, A1060, and A1050

AA1200 Aluminum This alloy, part of the 1200 series, is highly valued for its excellent corrosion resistance and formability. The anodized AA1200 sheets are ideal for applications requiring superior reflectivity and aesthetic finish, such as in lighting fixtures and ceiling tiles.

A1060 Aluminum Known for its high purity, A1060 aluminum also benefits from a favorable anodizing quality, enhancing its surface properties. Its applications include electrical and chemical industries, where outstanding conductivity is required alongside protection against corrosion.

A1050 Aluminum This alloy offers excellent workability and is characterized by a balance between thermal and electrical conductivity. Anodized A1050 sheets suit applications in food processing and industrial environments, ensuring hygiene and durability in machinery.

Applications of Anodized Aluminum Sheets

-

Architectural Elements: Anodized aluminum sheets are prevalent in construction and architecture. Facade systems, window frames, and ornamental elements benefit from the aesthetic versatility and protection against environmental factors.

-

Automotive Industry: Lightweight and corrosion-resistant aluminum sheets are essential in automotive manufacturing. They help in weight savings, improving fuel efficiency while enhancing component durability.

-

Electrical Applications: Anodized aluminum shows excellent electrical characteristics, making it suitable for electrical housings and conductors. High-purity alloys like A1060 welcome their residence in electrical outlets and conductors due to their conduction capabilities.

-

Consumer Goods: Various consumer goods, such as kitchen appliances, sporting equipment, and electronics, utilize anodized aluminum sheets to ensure a vibrant finish while maintaining structural integrity.

https://www.al-alloy.com/a/anodized-aluminum-sheet-aa1200-a1060-a1050.html