Aluminum 1050 h14

When we think of aluminum, we often picture shiny cans or foil sitting tight in our kitchen cabinets. But did you know there’s a special grade of aluminum that stands elegantly in places you might never consider? Enter Aluminum 1050-H14, a lightweight powerhouse quietly behind the scenes.

The Lowdown on Aluminum 1050-H14

At a glance, you might wonder why 1050-H14 gets so much credibility in the world of metal. The truth is, it’s all about its composition and treatment. This alloy is 99.5% pure aluminum, adding to its chemistry some properties thanks to the H14 tempering, which indicates strain-hardened but not heat-treated. To break it down: it’s stronger than pure aluminum, features excellent corrosion resistance, and offers exceptional formability. That’s a gold star for any potential application!

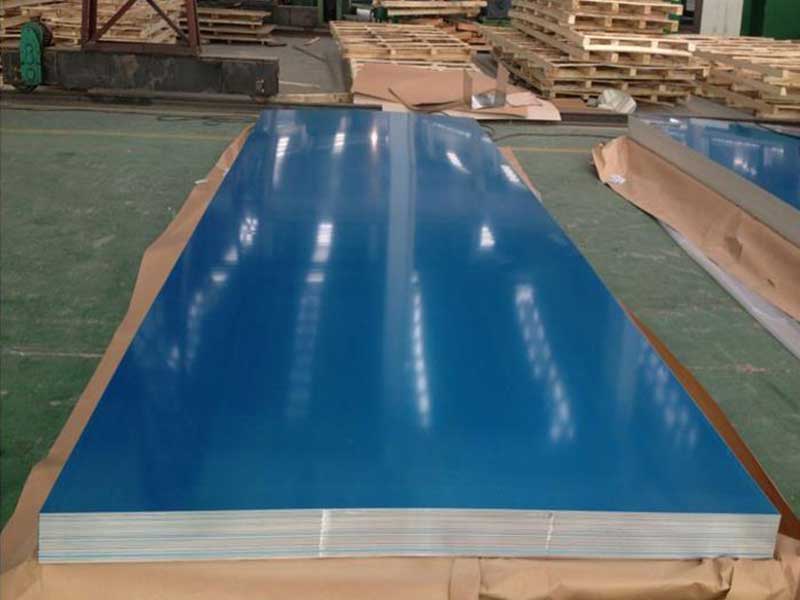

Aluminum 1050 H14 is a workhorse in our sheet production line, prized for its excellent formability and relatively high corrosion resistance. We often see it used in applications requiring deep drawing or complex shapes, like food and beverage containers or architectural components where seamless aesthetics are crucial. However, its softness, a direct consequence of its high purity, presents unique challenges. Scratches and surface imperfections are easily induced during handling and processing, necessitating careful attention to tooling and handling procedures throughout the manufacturing process. We've found that even minor variations in lubrication during stamping operations can significantly impact the final product's quality, leading to increased scrap rates if not carefully managed. Optimizing die design to minimize friction and employing appropriate surface protection measures are essential to maximize yield and maintain consistent product quality.

While its softness is a constraint, it’s also a advantage. The ease of forming translates directly to reduced energy consumption during fabrication, a crucial factor in today's environmentally conscious manufacturing landscape. Our experience shows that using 1050 H14 often leads to faster production cycles compared to harder alloys, especially in high-volume applications. We've also noted that the inherent reflectivity of this alloy is a beneficial feature for applications requiring specific light reflection properties. However, this same reflectivity can make detecting subtle surface defects more difficult during quality control inspections, highlighting the need for thorough and sophisticated inspection techniques. Ultimately, the specific

Lightweight Yet Durable

One of Aluminum 1050-H14's standout traits is its remarkable weight-to-strength ratio. In practical terms, this means that while you’re reducing payload, you're not sacrificing structural integrity. Think about industries reliant on lightweight components: automotive and aerospace are prime examples. Engineers can shape and incorporate this alloy without overshadowing the performance they aim for.

Easy Workability Meets Precision

For manufacturers, creating parts from 1050-H14 is as breezy as can be—think cookie dough as an analogy. It hardens without a fuss and shapes easily, making it fantastic for various production techniques like welding and machining. This flexibility extends to creating intricate designs, precisely where beauty meets functionality. If you're in the business of bespoke products or architectural structures, you will find its ability to fulfill precise requirements incredibly beneficial.

Unbeatable Corrosion Resistance

Let’s not overlook one of 1050-H14's critical advantages: corrosion resistance. This feature comes boldly into play for usages that involve exposure to harsh weather, moisture, or corrosive substances. Whether it's in chemical plants or outdoor signage, products made from this alloy can laugh in the face of oxidation. Durable and dependable, you won’t see this component pressuring your maintenance department with pesky rust and reparations.

Real-Life Applications

Still wondering where Aluminum 1050-H14 makes its debut in real life? From the engine compartments in your car to food processing plants, it’s indispensable. As we touch upon hobbyist hobbies, DIY enthusiasts should know that it’s excellent for crafting projects, be it for functional tools or minimalist art pieces! Moreover, the aerospace sector employs this material in airframes due to its excellent properties, making it a favorite for improving fuel efficiency without foregoing safety.

Think commercial buildings, too. With its amazing reflective properties, you might find it framing brilliant ideas in modern architecture—think sleek facades that offset energy consumption while showcasing handsome aesthetics.

Exciting Future Ahead

Looking ahead, the world craves sustainable solutions. With an ever-growing spotlight on conducting business twofold—championing both performance and eco-friendliness—Aluminum 1050-H14 is set to keep gaining momentum. Its recyclability and energy efficiency mean usage across green technology—an alliance in contributing to planetary defense.

In summation, while Aluminum 1050-H14 may not grab the headlines, it undoubtedly illustrates how a humble component can radiate functionalities and applications with equal fervor. As you gear up for your next project or simply take a sip from an aluminum can, pay homage to the beauties of everyday elements superbly working behind the scenes. Aluminum 1050-H14 may be unexpected, but relying on its possibilities is certainly a delightful surprise! Who knew aluminum could pack so much punch?