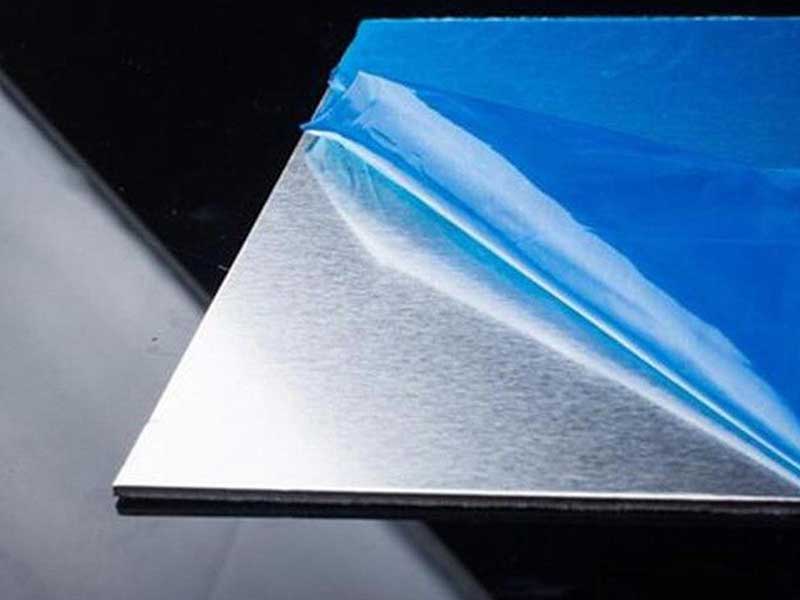

1050 1060 1100 3003 Aluminium Plate

Aluminum plates are pivotal in various industries due to their lightweight characteristics, corrosion resistance, and excellent thermal conductivity. Among the numerous aluminum alloys available, the 1050, 1060, 1100, and 3003 grades are especially notable.

1. Overview of Aluminum Alloys

When it comes to aluminum plates, each alloy is celebrated for distinct properties attributable to its composition. Let’s break down the defining aspects of the 1050, 1060, 1100, and 3003 aluminum plates.

1050 Aluminum Plate

The 1050 aluminum plate is renowned for its high corrosion resistance and remarkable thermal and electrical conductivity. It boasts an aluminum purity of 99.5%, making it ideal for applications that require excellent translucency and an enticing surface finish. Common uses include:

- Reflectors for lighting fixtures

- Heat exchangers

- Food and chemical processing

1060 Aluminum Plate

Like the 1050 variant, the 1060 aluminum plate contains a purity level of 99.6%, establishing itself as a popular choice for various manufacturing needs. Its ability to withstand oxidation makes it suitable for roofing, siding, and various industrial applications. Applications include:

- Electrical applications

- Chemical handling equipment

- Marine environments

1100 Aluminum Plate

The 1100 aluminum plate is a versatile alloy with substantial formability and ductility. It can withstand rigorous processing, allowing it to be shaped and welded easily. This type of aluminum is especially useful in food processing and heat-exchange applications. Key benefits include:

- Excellent corrosion resistance

- Good thermal conductivity

- Ease of machining

Common applications look like this:

- Cookware

- Storage tanks and pressure vessels

- Decorative and architectural applications

3003 Aluminum Plate

The 3003 aluminum plate is an alloy primarily known for its moderate strength and excellent workability. Containing approximately 1.2% manganese, it is significantly more durable than its 1000 series counterparts while maintaining a lightweight structure. Its characteristics make it a favorite in various sectors including:

- Fabrication and manufacturing

- Automotive applications

- Ducting and heating equipment

2. Selecting the Right Aluminum Plate for Your Needs

When deciding among 1050, 1060, 1100, and 3003 aluminum plates, one must consider specific application requirements:

- Corrosion Resistance: If your application is exposed to harsh environments, consider 1050 or 1060 for their superior corrosion-resistant properties.

- Formability: For projects requiring more extensive shaping or welding, the 1100 and 3003 plates offer better flexibility for intricate designs.

- Conductivity: When thermal and electrical conductivity are paramount, their high-purity characteristics make 1050 and 1060 exceptional candidates.

https://www.al-alloy.com/a/1050-1060-1100-3003-aluminium-plate.html