Single mirror aluminum plate

The Multifaceted World of Single Mirror Aluminum Plates: Functions and Applications

In today’s fast-paced world where functionality meets aesthetics, the single mirror aluminum plate has emerged as an indispensable materials choice across multiple industries. This brilliantly reflective material combines lightweight strength with a remarkably smooth finish, making it a favorite among architects, designers, and engineers alike.

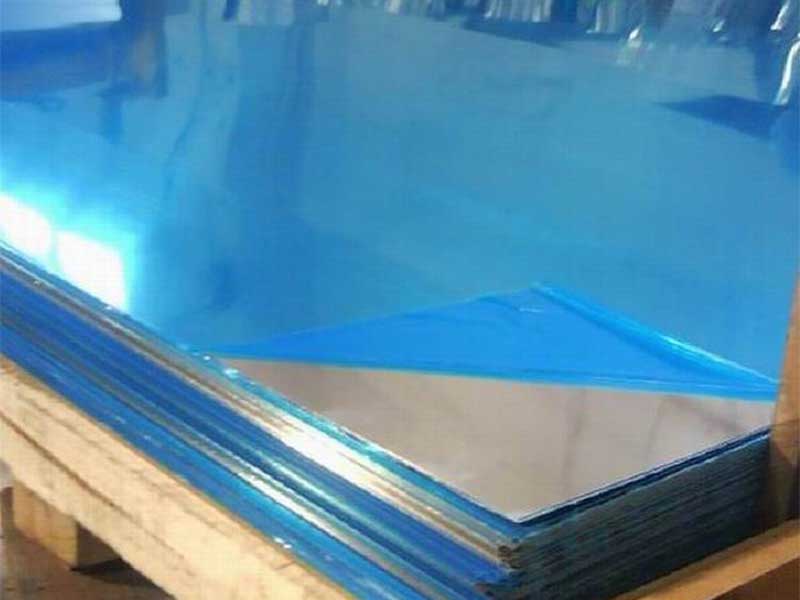

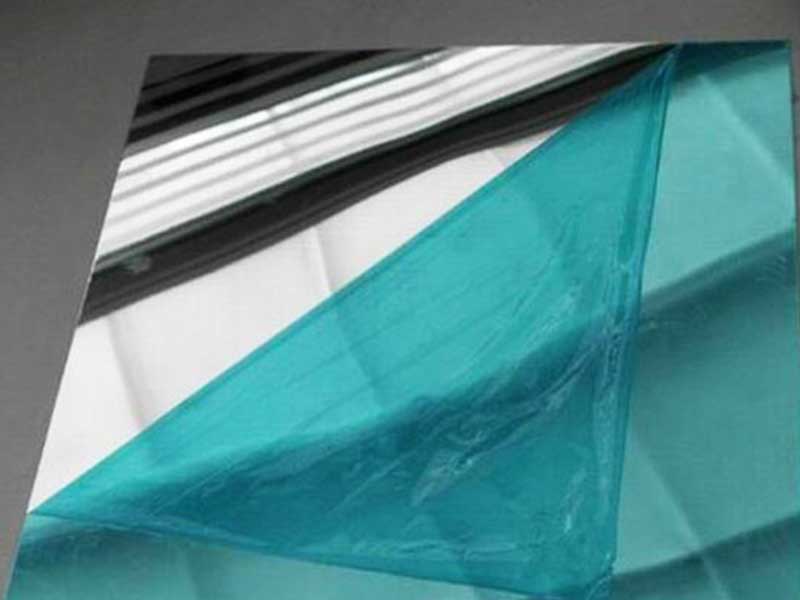

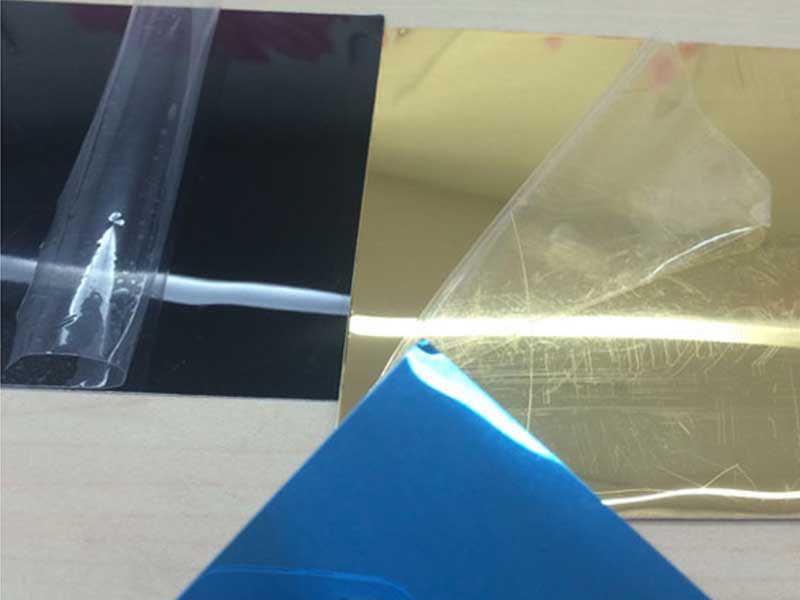

Working with single mirror aluminum plates presents unique challenges compared to handling sheets in bulk. The biggest concern is surface damage. Even minor scratches or fingerprints during handling, storage, or transportation can significantly impact the reflectivity and thus the value of the product. We've found that specialized handling techniques, including the use of protective films, specialized gloves, and even air-cushioned packaging, are crucial to prevent damage. Furthermore, the precise alignment and positioning of individual plates during applications like laser cutting or etching are critical for consistent results. A slight misalignment can render an entire plate unusable. Our process includes meticulous quality control checks at every stage, from incoming inspection to final packaging, to minimize losses due to surface defects.

Beyond surface integrity, controlling the precise flatness of a single plate is paramount, especially for applications demanding high precision like optical instruments or specialized reflectors. Even slight warping or bowing can lead to significant distortions and compromise performance. We utilize specialized jigging and clamping systems during the fabrication process to minimize warping and ensure dimensional accuracy. Furthermore, the specific application of the plate is crucial; a plate intended for decorative purposes has different tolerance requirements compared to one designed for high-precision optical use. This necessitates a detailed of customer specifications and adapting our handling and quality control procedures accordingly.

Unveiling the Basic Industry Specs of a Single Mirror Aluminum Plate

At the heart of its capabilities is its composition—usually composed of high-grade aluminum with a flawless treatment process that optimizes reflectivity while minimizing weight. Generally fabricated to exhibit a thickness ranging from 0.5 mm to 4 mm, a mirror aluminum sheet effectively captures and reflects up to 87% of light, offering stunning visual appeal. The aluminum’s light weight—typically despite its strength—pairs with its durable finish, making it ideal for many indoor and outdoor applications.

Architectural Marvels

One of the standout applications of single mirror aluminum plates is the architecture and interiors sector. These metal sheets are increasingly used in modern buildings, office fit-outs, lobby designs, and reflective ceilings. By incorporating a single mirror aluminum plate, architects create an ambiance of openness and luminosity, making spaces appear larger and brighter. Furthermore, its UV-resistant properties and corrosion resistance ensure a longevity that organic materials can’t promise, minimizing maintenance in iconic structures like shopping malls and public installations.

The Automotive Edge

In vehicle and fleet design, the sleek aesthetic provided by single mirror aluminum plates plays both a practical and postmodern visual role. Lightweight tailored fittings enhanced with mirror aluminum optimize performance efficiency by reducing the vehicle's overall weight while simultaneously maintaining structural integrity. An aesthetically pleasing automobile not only elevates consumer value but also reflects an era of green automotive innovations focused on sustainability without compromising design brilliance.

Retail Sector Amplification

Store displays thrive on impeccable visuals, and the single mirror aluminum plate serves as a premier option for enhancing merchandise presentation. Mirrors strategically constructed from this powerful material amplify color vibrancy and make items shine, ultimately decreasing inventory turnovers. Retailers talent in its imaginative applications—such as showcased fabrics, sides of shelves, and branded stands—taking full advantage of the visual trickery and attraction potential inherent in reflective surfaces.

Technology Innovations

The tech industry is transcending boundaries in utilizing mirror aluminum plates within screen fabrication and housing for electronic devices. Precision glass-clad metal components maximize optical visibility and aesthetics, rightly complementing the modern gadgets of today. This reflective surface finds its applications across lighting industries as well, helping us create compact setups while staying energy efficient—a testament to how single mirror aluminum contributes significantly to designs not purely reliant on functionality.

The Takeaway

A closer examination of single mirror aluminum plates reveals their multifunctional attributes, adaptability, and aesthetic appeal across an array of industries. From enhancing building façades to making a fashion statement in automotive designs, or revamping retail experiences, their benefits are profound and diverse. Perhaps most importantly, as the fields of design, automation, and retail move further into holographyc enhancement with a conscious effort toward sustainability, the relevance of single mirror aluminum plates cannot be overdeclared.

Investigating this remarkable material enables manufacturers to appreciate how synergy between aesthetic application and technological advancements allows the dual promise of design elevated alongside standard endurance.

As you explore or consider your next project, think about the wonders of a single mirror aluminum plate—the brilliant reflective quality and diverse functionalities eagerly await providing your ideas with complements or enhancements unsurpassed in today's fabricational ingenuity.

https://www.al-alloy.com/a/single-mirror-aluminum-plate.html