Anodized Aluminum Mirror sheet and coil

When you think about aluminum, your mind may drift to mundane structures like cans or plain tubing.

Shining Bright: The Anodizing Process

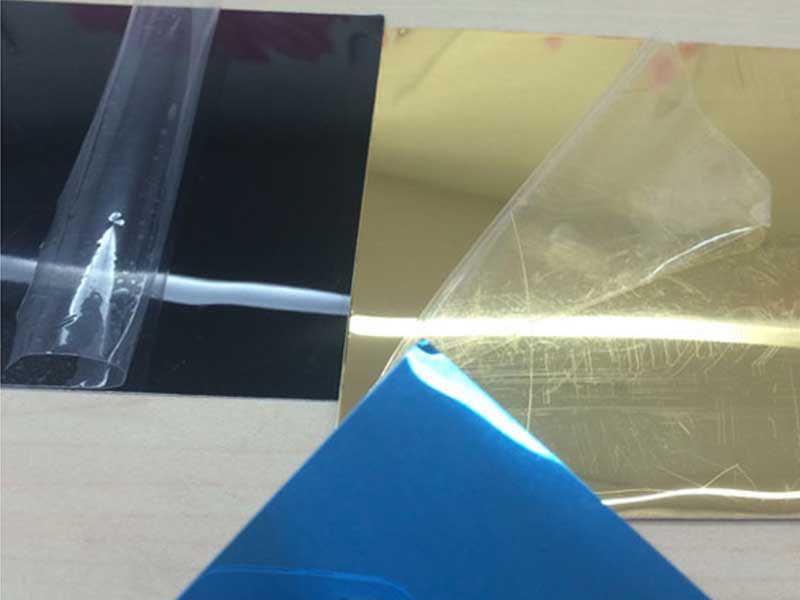

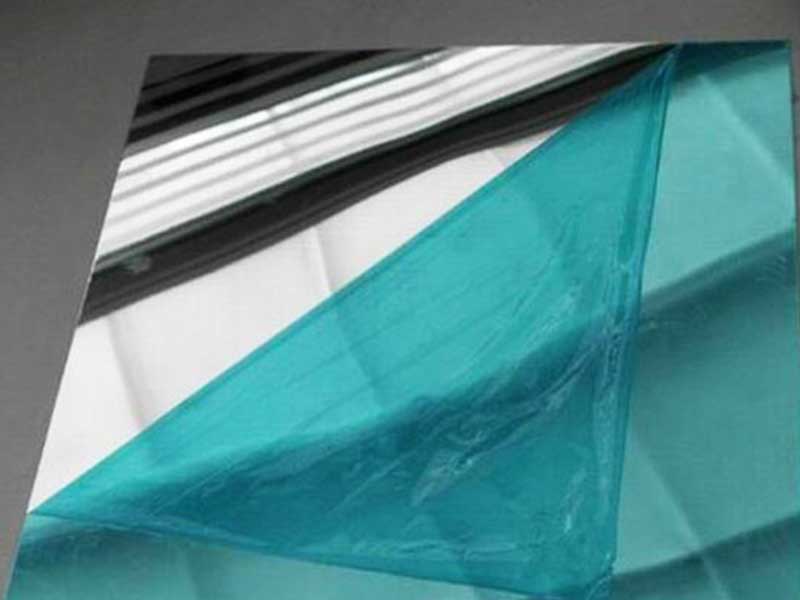

So what exactly is anodizing? Great question! Imagine bringing a piece of aluminum to life by giving it a sophisticated makeover. Anodizing involves coating bare aluminum with a protective oxide layer, giving it that dazzling mirror finish while significantly boosting its resistance to corrosion, scratches, and even harsh weather. Think of it as a superhero cape—a layer of protection while still managing to shine bright and perform at its best!

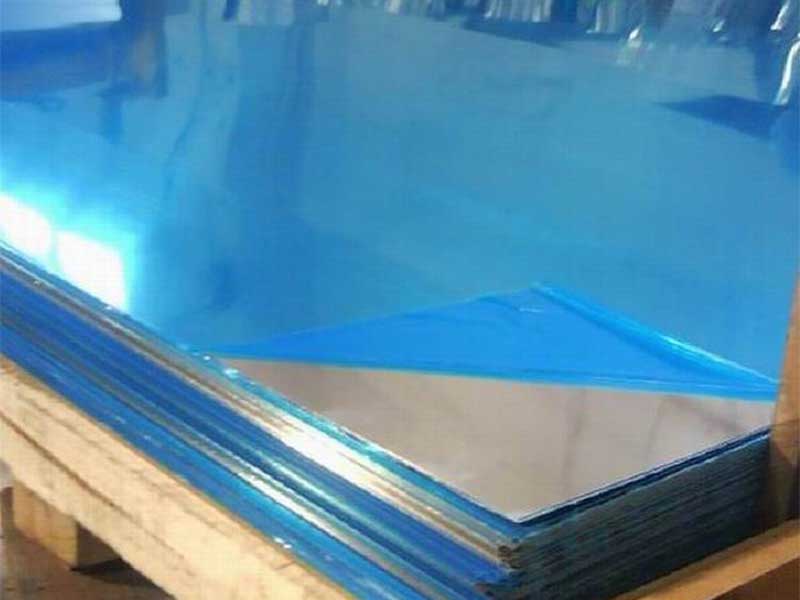

Working with anodized aluminum mirror sheet and coil daily, I've come to appreciate the intricate balance between aesthetics and durability it represents. The anodization process itself is fascinating – witnessing the transformation from a bright, easily scratched surface to a hard, corrosion-resistant finish is quite remarkable. We see a wide variety of applications come through, from high-end architectural cladding demanding flawless reflectivity to more industrial uses where resistance to harsh chemicals is paramount. The subtle variations in anodization depth and color – often unnoticed by the average customer – are a constant source of discussion and problem-solving among our team, ensuring we consistently meet the exacting specifications of each order. It's a complex material, and its nuances is critical to producing a high-quality product.

Personally, I find the interplay between the manufacturing process and the final product's performance endlessly engaging. A minor tweak in the anodizing bath's temperature or current can dramatically affect the final reflection and durability. Troubleshooting defects, like pinholes or uneven coloring, requires meticulous investigation and often involves collaborating with other departments. These challenges, however, are what make the job rewarding. Seeing our finished product, reflecting light perfectly and holding up against the elements for years to come, is a testament to the precision and dedication of everyone involved in the process, from the initial aluminum rolling to the final quality control check. It's more than just a sheet of metal; it's a reflection

This specialized surface technique not only enhances the esthetic appeal (cue appreciation for the beautiful reflective properties) but also heightens its durability. You won't find it easily dulled or scratched, standing the test of time in an array of conditions. How’s that for multitasking?

An Array of Applications

Anodized aluminum mirror sheets and coils boast versatility, showing up in more places than you might imagine:

-

Architectural Marvels: Need to make a building more eye-catching? Those staggering skyscrapers or shimmering malls typically employ anodized mirror finishes to create stunning reflections. This not only elevates the modern appearance but also contributes to energy efficiency by reflecting sunlight, keeping enhanced heat in mind.

-

Decorative Elements: The aesthetic charm isn’t limited to massive constructs! These mirror sheets find a place in interior decor—think stunning wall installations, elegant furniture pieces, and striking artistic installations. It’s like taking the sleek modern vibe to a whole new reflective level in your interior design projects.

-

Lighting Solutions: Those airy, bright light fixtures you've fallen in love with? They often utilize anodized aluminum in cheeky and clever ways to improve reflectivity and control light distribution, increasing not only visual class but also energy efficiency.

-

Electronics and Appliances: Keeping up with tech, the reflective nature of mirror aluminum is leveraged in various consumer electronics, from home appliances to high-end gadgets. Its lightweight body paired with striking appeal? Sign us up!

Beyond the Surface

Though the initial impression may be that mirroring fastidiously enhances visual surroundings, the sheer engineering behind anodized aluminum speaks volumes. Lightweight without sacrificing strength, its sustainability factor plays well with ecological-minded folks—aluminum can be recycled with tenacity. Having the perfect blend of attractiveness and functionality, it’s a product that deserves appreciation beyond its shining exterior.

Making the Right Choice

Before diving headfirst into the realm of mirror aluminum, think about what you really need. Whether you desire strength, aesthetic appeal, or versatility, anodized aluminum delivers reliably across the board. In short, consider your specific requirements and the benefits this metal regal would bring to the table, and you're set for success.

Wrapping Up

So there you have it—an in-depth look at anodized aluminum mirror sheets and coils from a lens replete with admiration for its functions and rich terrain of applications. Whether you’re decorating your home, designing innovative architectural facades, or even ramping up vehicle style, remember that behind every shiny surface lies a world of multifaceted utility waiting to dazzle you. Shine on, marvelous metal!

https://www.al-alloy.com/a/anodized-aluminum-mirror-sheet-and-coil.html