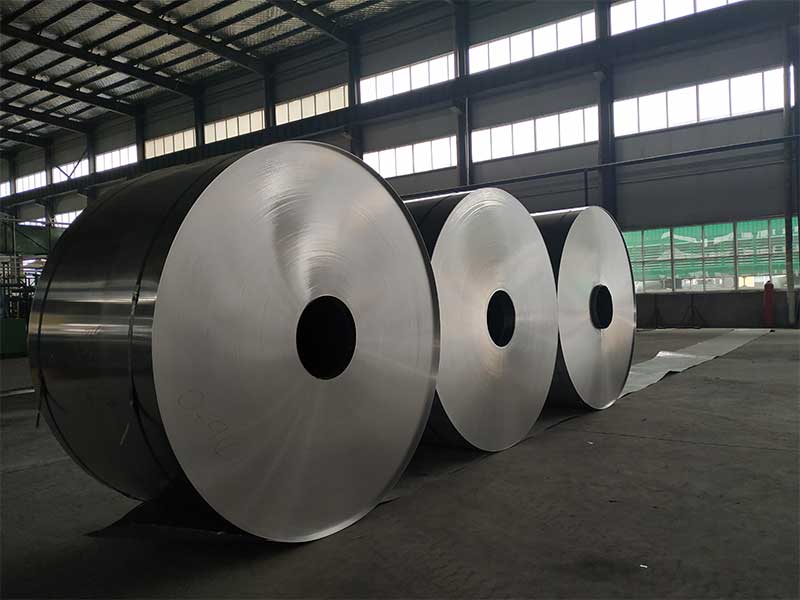

Mill finish cleaning aluminum coil

Aluminum coils are hailed for their versatility in various industries, ranging from automotive to construction. Among the numerous stages in their production, the stage of mill finish cleaning is one of the most crucial and intriguing. This process not only enhances the aesthetics of the coils but also plays a pivotal role in their overall quality and performance.

What is Mill Finish Cleaning?

Mill finish cleaning refers to the process of preparing aluminum coils immediately after manufacturing in the mill. Conceived originally to enhance surface quality by removing any oxidation, dust, and manufacturing residues, this stage of processing ensures that the aluminum coil emerges ready for diverse applications—from further processing to installation.

Mill finish cleaning of aluminum coil is a deceptively complex process, far more nuanced than a simple "wash and dry." We're not just dealing with dirt; we're contending with rolling oils, lubricants, and various processing residues that can profoundly impact the coil's subsequent applications. My experience shows that the subtle variations in the alloy composition – even within the same batch – necessitate adjustments to our cleaning parameters. A cleaning solution perfectly suited for 3003 alloy might leave streaks on 5052, highlighting the need for precise control and constant monitoring of chemical concentrations and temperature. Furthermore, the subtle differences between various cleaning systems – from alkaline to acidic baths, to electrolytic processes – mean we're always fine-tuning to optimize efficiency while maintaining the highest quality finish.

Beyond the chemical aspects, the mechanical handling of the coil during the cleaning process is equally critical. Improper tensioning during unwinding and rewinding can lead to scratches or surface imperfections that negate the benefits of a thorough chemical clean. We've experimented extensively with different rollers and guide systems, constantly searching for ways to minimize coil damage while maximizing throughput. The seemingly minor details – the type of brush used, the drying air pressure, even the ambient humidity – all play a role in the final product quality. It's this intricate interplay of chemistry, mechanics, and meticulous attention to detail that truly defines successful mill finish cleaning of aluminum coil, and separates a good coil from

The Functions of Mill Finish Cleaning

The primary function of mill finish cleaning is to ensure a clean and stable surface of aluminum that is ready for subsequent finishing processes, if needed. Here are several critical functions achieved through this process:

1. Oxide Removal

Aluminum, by its nature, is prone to oxide formation on its surface due to exposure to air and moisture. Using an appropriate cleaning solution helps dissolve layer of manganese oxide, rendering the coil pristine—a must-have for applications like mirror finsh products.

2. Preparation for Coating

One of the industries that benefit significantly from this process is the building sector where aluminum cladding is widespread. A clean mill finish ensures better adherence to paints and finishes, thereby extending longevity and durability.

3. Enhanced Visual Appearance

For aesthetic applications, such as in architectural details and decorative parapet elements, a spotless surface enhances the visual appeal. It allows for reflective finishing or polishing, accentuating the unique characteristics of aluminum.

Technical Insights into the Process

The technical details of mill finish cleaning involve several steps that play essential roles in varying stages of the finishing encapsulation.

Effective Cleaning Agents

During the process, various chemical cleaning agents, including alkaline-based solutions and specially formulated acid baths, are spurred into action. This chemical choice hinges on operational efficiency and safety—avoiding harmful substances while ensuring peak performance efficiency.

Temperature Control

Temperature regulation during the cleaning process is vital. Utilizing warm alkaline cleaners, often maintained several degrees higher than room temperature, improves reaction rates and ensures thorough cleaning without damaging the aluminum base.

Machinery and Technology Utilized

Pipeline technology, high-pressure water jets, and advanced drying methods significantly modernize the cleaning procedure. Such technologies not only minimize labor but also maximize efficiency, yielding an environmentally expedient and streamlined process.

Applications That Showcasing Mill Finish Aluminum Coils

The myriad applications of mill-finished aluminum coils span across sectors, showcasing the significance of cleaning in enhancing the utility of these materials:

-

Architecture & Construction: Aluminum is widely used in façades, roofing, windows, and interior designs, making mill finish cleaning indispensable for conflict-free integration.

-

HVAC Systems: Coil manufacturing used in heating and cooling applications relies on clean surfaces to ensure optimal functionality and energy efficiency.

-

Automotive Components: Motor covers and structural announcers benefit by presenting finished aluminum components that stay compliant with stringent quality norms.

-

Consumer Electronics: Clean, smooth surfaces provide consistent customer satisfaction in aesthetic delivery for cases and parts of household appliances.

https://www.al-alloy.com/a/mill-finish-cleaning-aluminum-coil.html