1060, 3003,5052 mirror aluminum sheet

1060, 3003, 5052 Mirror Aluminum Sheet: A Comprehensive Guide to Features and Applications

Explore the vibrant world of mirror aluminum sheets—1060, 3003, and 5052. Dive into the unique characteristics and versatile applications of these alloys, how their distinct properties drive both aesthetic and functional advantages across industries.

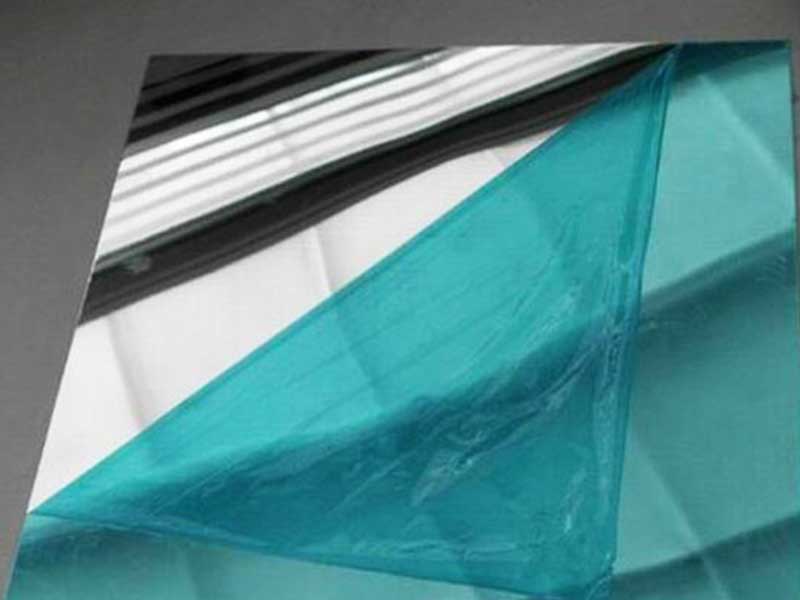

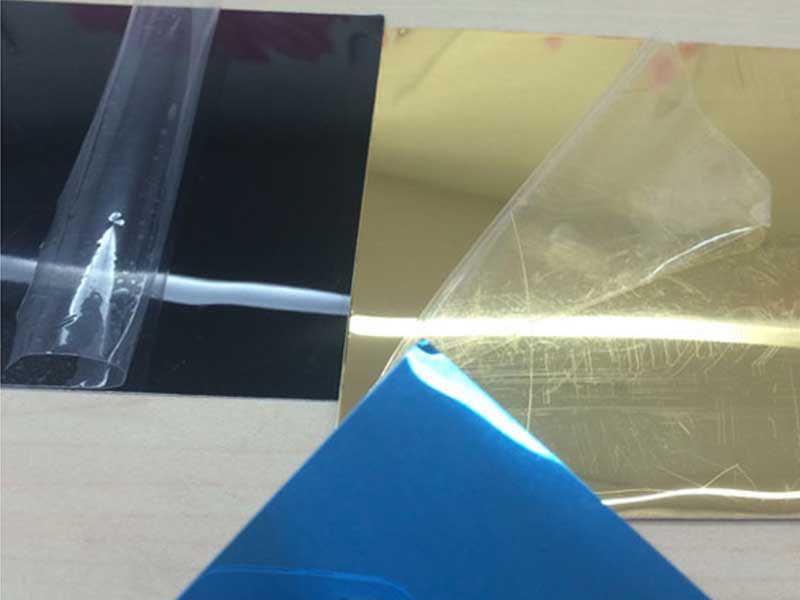

Working with 1060, 3003, and 5052 mirror aluminum sheet daily gives me a unique appreciation for the nuances of each alloy. 1060, being almost pure aluminum, is a dream to work with – incredibly soft and easily formable. Its high reflectivity is superb, making it ideal for applications demanding pristine mirroring. However, its softness is a double-edged sword; it scratches easily and is less resistant to wear and tear than its alloyed counterparts. We often see it used in decorative applications or where a high-polish finish is paramount but durability is less critical. 3003, with its manganese addition, offers a significant improvement in strength and workability compared to 1060, though its reflectivity isn't quite as brilliant. It’s a good compromise when you need some added durability without sacrificing too much on the mirror finish.

5052, on the other hand, is a whole different beast. Its magnesium alloying brings exceptional corrosion resistance, a crucial factor in many outdoor or marine applications where we see it frequently used. While it's harder to polish to the same dazzling shine as 1060, the resulting mirror finish is very durable. Personally, I find the slightly more challenging polishing process for 5052 rewarding; the final product’s resilience is a testament to the effort. The distinct properties of each alloy – softness, strength

Introduction

Aluminum is undeniably one of the most versatile metals used across various sectors due to its enduring strength, lightweight nature, and resistance to corrosion. Mirror aluminum sheets specifically is know not only for their practicality but also their dazzling aesthetics.

the Alloys

1. 1060 Aluminum Alloy Developed primarily for its excellent corrosion resistance and ductility, the 1060 alloy contains a minimum of 99.6% aluminum. Its inherent qualities include:

-

High Reflectivity: 1060 alloy takes the lead with unparalleled reflectance rates, making it the preferred choice for applications requiring illumination or reflection.

-

Ease of Fabrication: With good weldability and formability, it easily adapts to the needed shapes without sacrificing strength.

These attributes make it particularly suited for applications in the architectural and decorative arena, like ornamental designs, ceiling tiles, and LED lighting fixtures.

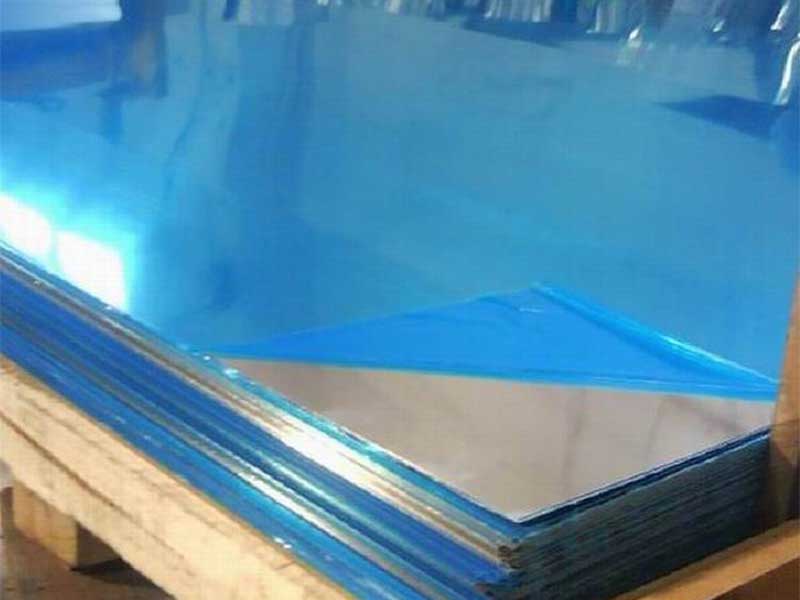

2. 3003 Aluminum Alloy The 3003 alloy contains manganese as its principal alloying element, granting it additional strength over the purely aluminum 1060. features include:

-

Workability: The alloy possesses excellent workability, allowing it to be easily formed, drawn, and welded without substantial loss of strength.

-

Resistance to Traditional Corrosion: It demonstrates robust corrosion resistance, which is prescient in the automotive-relevant applications and household appliances.

The 3003 mirror aluminum sheets take advantage of these properties, often used in kitchen backsplashes, truck bodies, and decorative wall panels that not only need strength but also aesthetic finish.

3. 5052 Aluminum Alloy A step higher in strength from 3003, the 5052 alloy is magnesium-based and champions commendable ductility. This offers unique benefits including:

-

Superior Formability: Highly pliable alloy with great bending capabilities lends itself well to complex geometries needed in design projects.

-

Enhanced Durability: Exhibiting excellent stress corrosion cracking resistance makes it indispensable in marine and automotive applications where load and durability formulates factors.

The integrative benefit of 5052 is particularly applicable in marine environments (e.g., boat hulls), transport sectors (like trailer siding and roofs), and lighthouses, where moisture is consistently prevalent.

Industrial Applications

Architectural Design Aesthetic preference does usher practical implementation. Mirrored aluminum sheets are emblazoned in modern architecture used as cladding, creating reflective facades that offset and manipulate surrounding light, often resulting in an enchanting pattern. Offset hydrocarbon emissions through virtuous building concepts translates through sleek designs into energy-efficient masterpieces.

Automotive and Marine Industries Lightweight metal parts derived from these alloys sport lower fuel consumption while maximizing strength—essential characteristics for modern transportation complexes. Particularly relevant, they clinch rigid strength while offering visual appeal during roadside showcases for cars or glossy features within ships framed within reflective hoods.

Signage and Displays The urban clamor finds vitality in jingling brand avatars glinting under loose mercurial finance balances. Be it retail signage or artistic installations which convince beholding eyes at first glance fitting mirroring alloy offerings alongside stringent durability standards.

Final Thoughts

The choice of aluminum alloys alters perspectives—embracing their signature features mapped against design directive pathways initiates a linguistic metaphor in engineering. 1060, 3003, and 5052 mirror aluminum sheets belong not just paraphernalia of materials mercantile. Invest in the high reflectivity of 1060, the dependable outlook of 3003, and the robust resilience of 5052 for your next project; transcend EF W T RT fields and orchestrate aesthetic youth while under trending modern industrial thoroughfares. Leading choices not only compound deliverable profitability but aproned noted context-bound results. Choose wisely in these thin layers of reflective light more slightly create shadowplay with clarity seen—a future re-injected by refined metalwards.

https://www.al-alloy.com/a/1060-30035052-mirror-aluminum-sheet.html