Mirror Reflective 1100 H14 24 Aluminum

Mirror Reflective 1100 H14 24 Aluminum: The Unsung Hero of Shine and Functionality

When you think of reflective surfaces, perhaps a disco ball, sleek mirrors, or the stylish finish on your car comes to mind. But tucked away in the world of industrial materials is a superstar that’s just as reflective—but with a whole lot more to offer. Enter Mirror Reflective 1100 H14 24 Aluminum. It's the perfect blend of functionality and style, and it deserves a spotlight.

1100 H14 24 aluminum, specifically when targeted for mirror-like reflectivity, presents unique challenges in our manufacturing process. Achieving a truly specular surface requires meticulous control throughout the production chain. While 1100's inherent softness makes it relatively easy to work with and achieve a smooth finish, maintaining consistency across large sheets is crucial. Even minor variations in rolling pressure, annealing temperature, or surface cleaning can lead to inconsistencies in reflectivity, affecting the final product's quality and potentially causing rejection by customers with stringent aesthetic requirements. We've found that optimizing our electropolishing parameters is particularly vital; subtle changes in electrolyte composition and current density significantly impact the final surface finish and its ability to reflect light uniformly.

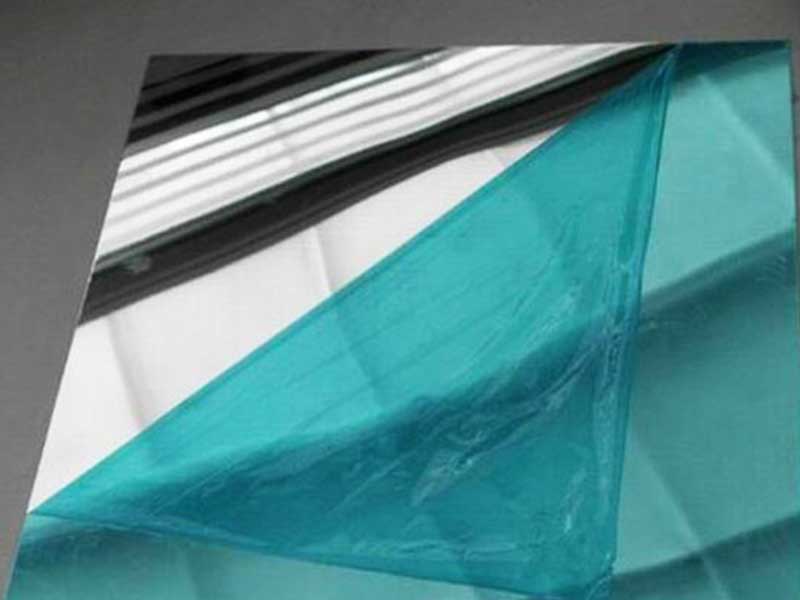

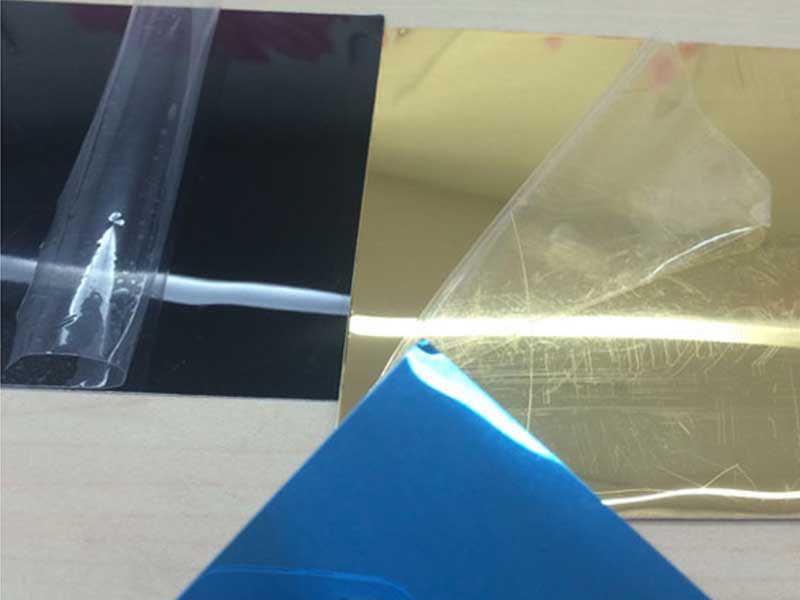

Beyond the manufacturing process, the 1100 H14 24 designation itself speaks to the material's limitations in terms of durability for certain applications. Its softer nature means it's more susceptible to scratching and marring during handling and transportation. We often see returns or complaints linked to surface damage incurred after the sheets leave our facility. Consequently, we've implemented improved packaging and handling procedures to minimize this risk. Furthermore, while its high reflectivity is a selling point, we educate our clients on the need for appropriate protective coatings in environments prone to corrosion or abrasion to maintain the mirror-like finish and extend the lifespan of the aluminum sheet.

What Makes It Reflective?

At a glance, the shiny surface calls for attention. The 1100 H14 designation refers to the chemical composition and tempering of the aluminum itself. In simple terms, the "1100" signifies that this alloy is at least 99% aluminum, while "H14" indicates it's been work-hardened and is part of the strain-hardened series. The result is a material that's not only lightweight but boasts excellent corrosion resistance and formability—attributes that will have any engineer nodding in approval.

So, why the mirror finish? This reflective quality predominantly stems from the surface treatment. Through applications like anodizing or specialized polishing, the aluminum transforms into a sleek mirror-like surface. Not only does it look stunning, but it packs serious functionality, too: higher reflectivity means better energy efficiency and visual impact.

Applications: Who Doesn’t Love Flexibility?

One of the most dazzling features of Mirror Reflective 1100 H14 24 Aluminum is undoubtedly its versatility. Here are a few striking applications—pun intended—that showcase its adaptability:

1. Architectural Wonders

Many modern building designs are leaning towards envelopes that dazzle. Whether it’s stunning façades or high-end interiors, architects and designers are using mirror-finish aluminum to create spaces that feel bigger and brighter. Think sleek office buildings reflecting their surroundings or commercial interiors that maximize natural light. It’s all about that aesthetics meeting function vibe!

2. Transportation Trends

In the aviation and automotive industries, reducing weight while maintaining performance is crucial. Mirror Reflective 1100 H14 24 Aluminum fits right in. Designers often incorporate this material due to its lightweight but sturdy properties. Places like heated cabin interiors and light fixtures hold our favorite reflective aluminum to create stylish, lightweight solutions that meet stringent industry standards.

3. Signage & Displays

For retail and advertising, capturing attention instantly is key. This aluminum brings a level of sophistication and vibrancy to signage that’s hard to beat. Its reflective properties help in enhancing visibility, making businesses look more prominent in a crowded marketplace. Plus, signage made from this material possesses the ability to withstand the elements without fading or corrosion, ensuring your message remains as bright and shinny as ever.

4. Lighting Applications

Reflective surfaces are also optimal for various lighting fixtures. Imagine brighter, more energy-efficient LED installations or recessed downlights utilizing this mirror finish to amplify light. The aluminum’s reflective quality can make every luminaire a lot more effective in light dispersion, ideal for both residential and commercial spaces.

A Chestnut with Layers

Let’s also talk about the eco-friendly aspect. Aluminum is profoundly recyclable; using Mirror Reflective 1100 H14 24 not only looks good but does good for the planet. In an age where companies are striving towards slowing climate change and adopting sustainable practices, reflecting this ethos in your choice of materials is savvy.

The Takeaway

In an ocean of options, Mirror Reflective 1100 H14 24 Aluminum stands out—even without much of a promotional tilt providing awareness for its merits. It’s not just the reflective surface that makes it captivating but the numerous applications and sustainability factor that transport it into the spotlight.

So, whether you're an engineer wanting to create a lightweight structure, an architect aiming for sleek, reflective looks, or even a business owner reshaping your storefront visibility, consider giving this unsung hero a chance in your next project. You might just be amazed at how effective—yet effortlessly stylish—this aluminum can actually be! Shine on, my friend!

https://www.al-alloy.com/a/mirror-reflective-1100-h14-24-aluminum.html