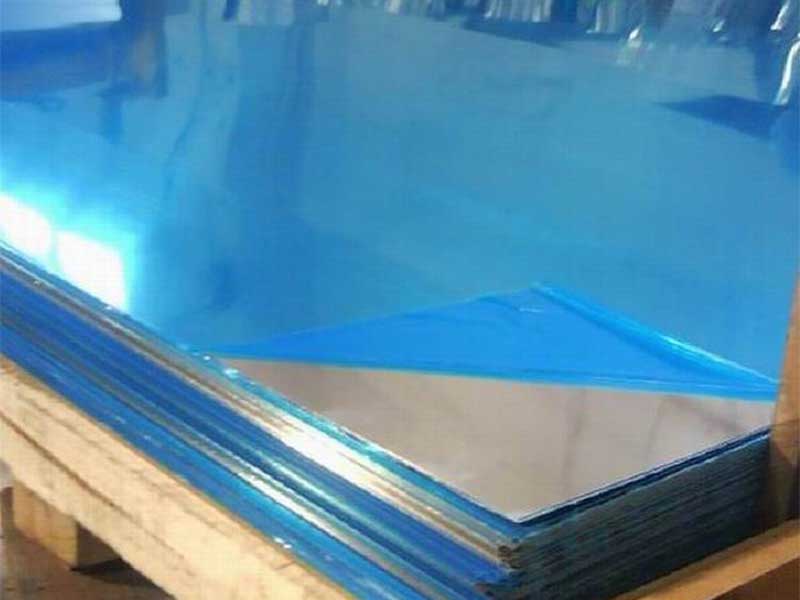

Mirror Finish Alloy Anodized Aluminum Sheet

Aluminum is known for its remarkable properties, including strength, lightweight, and resistance to corrosion. However, when combined with the state-of-the-art process of anodization and polished to a sleek mirror finish, it becomes even more versatile and visually appealing. A mirror finish alloy anodized aluminum sheet.

What is Alloy Anodized Aluminum?

Alloy anodized aluminum sheets are made from specific aluminum alloys, with addition elements enhanced to provide superior mechanical properties and performance. Anodization is an electrochemical process that hardens the surface of aluminum by creating a durable oxide layer. This treatment increases corrosion resistance while also enhancing the metal's aesthetic look.

Characteristics of Mirror Finish Aluminum

-

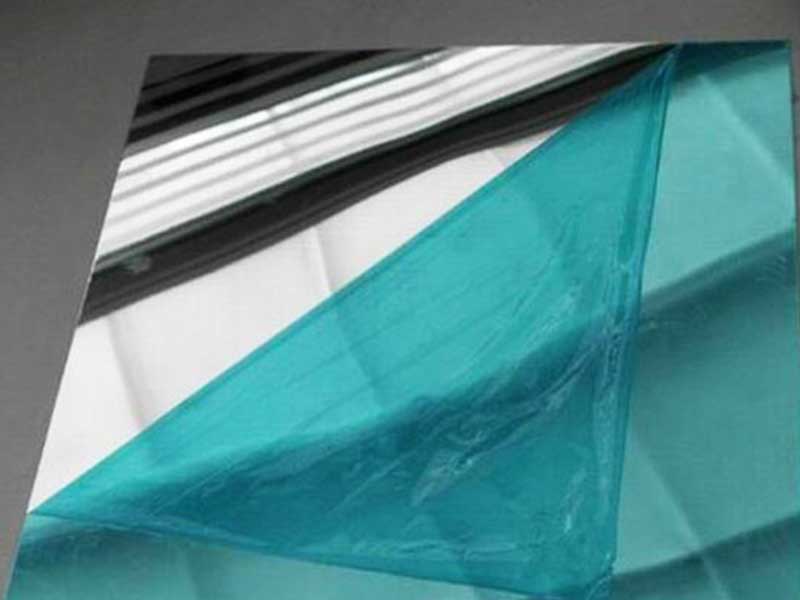

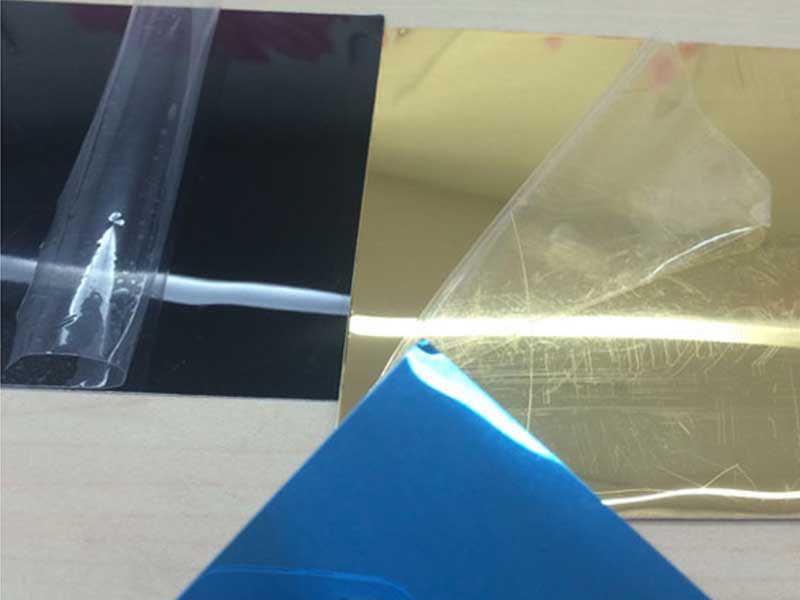

Aesthetic Appeal: The mirror finish of anodized aluminum sheets gives them an elegant, contemporary look that reflects surroundings beautifully, making them suitable for various design elements.

-

Durability: Anodized aluminum naturally withstands the wear and tear of everyday use. The anodization process hardens the surface, making it resistant to scratching and denting, which ensures longevity.

-

Corrosion Resistance: One of the primary benefits of anodized aluminum is its resistance to oxidation and corrosion. The anodized layer protects the aluminum, making it suitable even for the most challenging environments.

-

Easy Maintenance: The mirror finish is also easy to clean, requiring minimal maintenance. A simple wipe down with a soft cloth and mild detergent is sufficient to keep it looking splendid.

Applications of Mirror Finish Alloy Anodized Aluminum Sheets

Mirror finish alloy anodized aluminum sheets have become popular choices across various fields due to their unique properties:

-

Architectural Use: These sheets are often found in modern architecture, allowing designers to incorporate reflective elements into façades, ceilings, and interior designs, where they add a sense of spaciousness and sophistication.

-

Furniture Design: Their aesthetic quality lends itself well to contemporary furniture pieces. Mirror finish aluminum is resistant to wear and offers a sophisticated finish, adding an attractive custom look to tables, cabinets, and other furniture.

-

Electronics & Appliances: Since aluminum has excellent conductive properties, it is often utilized in the manufacturing of components for electronic devices. The mirror finish helps these devices beautifully blend into modern home settings.

-

Transport and RV Manufacturing: Lightweight yet satisfying decor criteria, widely used in trailers and mobile structures due to weight savings and enhancing exterior styling.

Choosing the Right Alloy

When selecting a mirror finish alloy anodized aluminum sheet, several factors should be taken into consideration:

-

Weight Requirements: Different alloys have different weights and strengths. It’s crucial to select a grade that meets the specific need of the application, considering both lifting capabilities and durability.

-

Thickness Needs: The thickness of the sheet will affect its performance, from 0.032 inches to thicker options for heavy-duty applications.

-

Intended Usage: Depending on the exposure conditions—interior or exterior use—the proper anodization level and mounting elements should be specified.

https://www.al-alloy.com/a/mirror-finish-alloy-anodized-aluminum-sheet.html