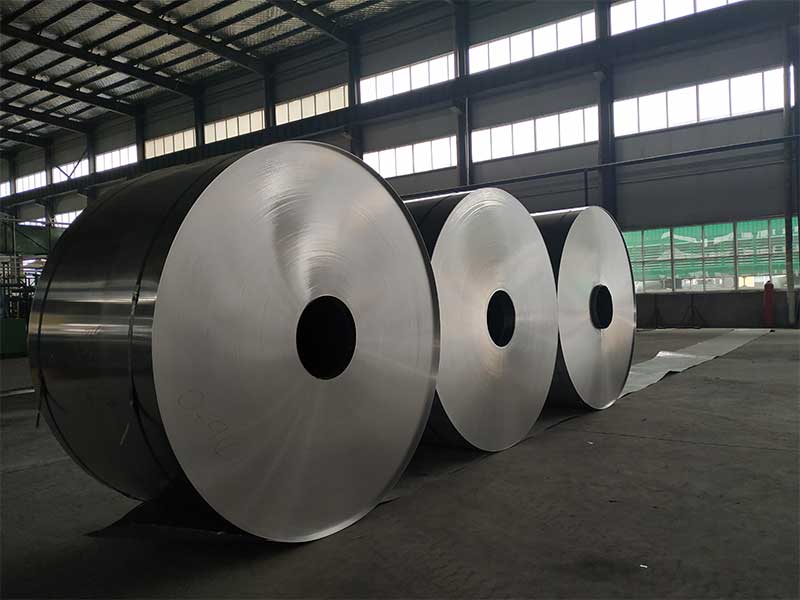

Aluminum coil AA 1050 1060 A3003 Temper H12

Aluminum coils have gained immense popularity across various industries due to their lightweight, durable, and corrosion-resistant properties. Among these, the AA 1050, 1060, and A3003 aluminum coils in temper H12 stand out for their unique features and broad applications.

Features of AA 1050, 1060, and A3003 Aluminum Coil

-

High Purity and Excellent Corrosion Resistance: One of the primary features of the AA 1050 and 1060 aluminum coils is their high aluminum content, exceeding 99%. This high purity results in exceptional corrosion resistance, making these aluminum coils ideal for applications exposed to the elements, such as chemical and food processing industries.

-

Formability and Workability: The temper H12 indicates that these aluminum coils have been strain-hardened and partially annealed, providing a moderate level of strength with good ductility. As a result, they can be easily bent, formed, and rolled into various shapes, which is essential for applications requiring intricate designs.

-

Thermal and Electrical Conductivity: Aluminum coils made from the 1050, 1060, and A3003 series are known for their remarkable thermal and electrical conductivity. This makes them suitable for heat exchangers and electrical components, enhancing their functionality in thermal management systems.

-

Lightweight Yet Strong: These aluminum coils offer an excellent strength-to-weight ratio, providing effective structural support without the excess weight. This feature is invaluable in industries such as automotive and aerospace, where reducing vehicle weight is a key focus to improve fuel efficiency.

-

Versatile Surface Finish: The ability to achieve a high-quality surface finish with AA 1050, 1060, and A3003 aluminum coils means they can easily be used as aesthetic elements in design. The polished or anodized finishes give those applications an appealing look, making them popular in architectural applications.

Applications of Aluminum Coil AA 1050, 1060, and A3003 in Temper H12

The aluminum coil series AA 1050, 1060, and A3003 in temper H12 are utilized across various industries, showcasing their versatility:

-

HVAC Systems: Due to their excellent thermal conductivity and ability to resist corrosion, these aluminum coils are widely used in heating, ventilation, and air conditioning (HVAC) applications. They are commonly employed in air ducts, heat exchangers, and radiators, providing efficient heating and cooling solutions.

-

Food and Beverage Packaging: The high levels of purity and corrosion resistance in these aluminum coils make them suitable for food storage and packaging. These coatings ensure hygiene and protection are maintained throughout the supply chain, preserving the freshness of food products.

-

Automotive Applications: The lightweight nature of these aluminum coils contributes to the automotive industry’s efforts to manufacture vehicles that consume less fuel. From body panels and interior components to cooling applications, the AA 1050, 1060, and A3003 coils provide durability and strength.

-

Electrical Applications: Given their exceptional electrical conductivity, these aluminum coils are also employed in producing wiring and electrical components. They ensure lower resistivity and enhance overall efficiency in electrical engineering designs.

-

Architectural Applications: Due to their aesthetic appeal and ability to withstand environmental factors, these aluminum coils are used in building cladding, roofing, and decorative interior applications. The ability to finish the surface to a high degree makes these materials a favored choice among architects and designers.

https://www.al-alloy.com/a/aluminum-coil-aa-1050-1060-a3003-temper-h12.html