Aluminum coil Mill Finish Aa 1100 1050 H18

Understanding Aluminum Coil Mill Finish: AA 1100 and 1050 H18

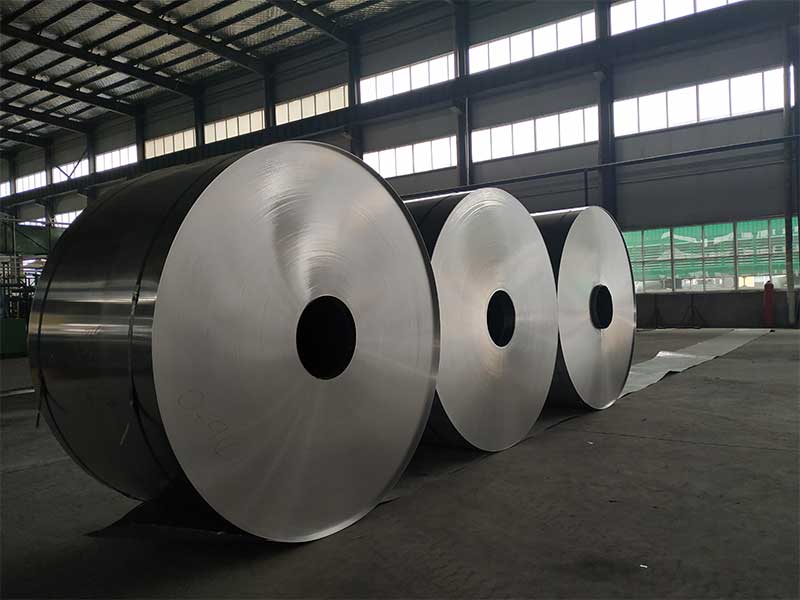

Introduction to Aluminum Coils

Aluminum coils are versatile materials widely used across various industries due to their lightweight, durability, and excellent corrosion resistance. Among the different grades of aluminum coils, AA 1100 and 1050, particularly in the H18 temper, are popular options for numerous applications. In this article, we'll delve into what aluminum coil mill finish means and explore the distinctive features of AA 1100 and 1050 H18.

What is a Mill Finish Aluminum Coil?

A mill finish aluminum coil refers to aluminum that has not undergone additional processing or treatment after being manufactured. This means the surface is in its raw state, exhibiting a natural metallic sheen finished according to conventional rolling processes. The mill finish is widely known for its smooth surface, which allows for easy application of coatings and paints, enhancing the surface finishing in subsequent use.

Features of AA 1100 and 1050 H18

- Composition and Characteristics:

- AA 1100: This alloy is primarily composed of 99% aluminum content, ensuring excellent corrosion resistance and high thermal conductivity. It is favored in chemical and food processing applications due to its commercial grade properties.

- AA 1050: Similar to the 1100 alloy, AA 1050 boasts around 99.5% aluminum. It is notably defined for its excellent formability and resistance to chemical attack, making it great for electrical applications.

- Temper H18:

- The "H" designation indicates the tempering process, where the metal is strain-hardened and aged to produce a specified mechanical property. The "18" signifies that the material is in hardened form, resulting in higher strength and optimized durability. This attribute is particularly valuable for manufacturers looking for materials that can withstand rigorous applications.

- Applications:

- Both AA 1100 and 1050 H18 coils are commonly used in various industries. Their properties make them suitable for items like heat exchangers, reflective surfaces, decorative trim, roofing sheets, and electrical appliances. The combination of strength, lightweight nature, and corrosion resistance allows these materials to thrive in multiple environments.

Benefits of Using Mill Finish Aluminum Coil AA 1100 and 1050 H18

-

Performance: The natural mill finish of aluminum coils accentuates their polished look while maintaining structural integrity. They perform excellently under heat and harsh weather conditions.

-

Affordability: Compared to processed finishes, mill finish aluminum coils come at a lower price point, making them budget-friendly for manufacturers.

-

Ease of Processing: The smooth surface allows for easy manipulation during fabrication, improving productivity and reducing machining costs.

https://www.al-alloy.com/a/aluminum-coil-mill-finish-aa-1100-1050-h18.html