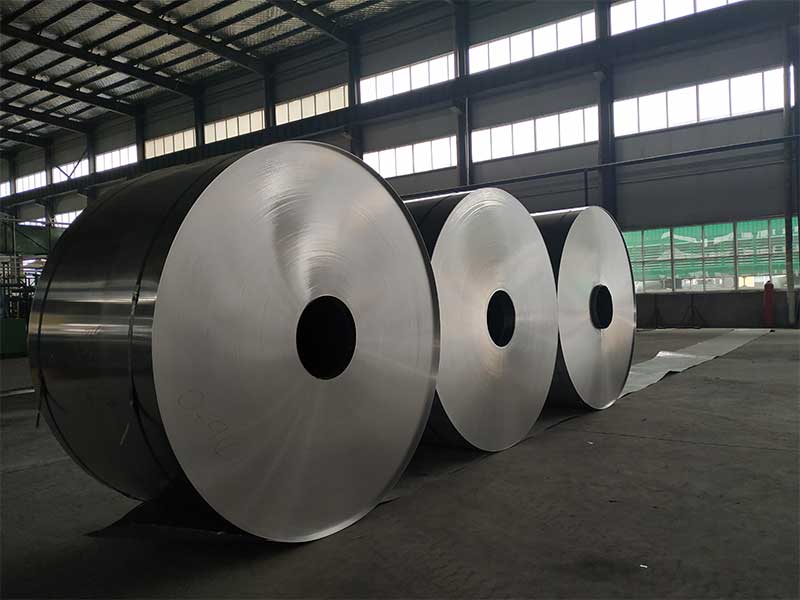

1050 H14 coating aluminium coil

In the realm of construction and manufacturing, aluminum coils have gained a significant foothold due to their various advantageous properties. Among these, the 1050 H14 coating aluminum coil stands out as a reliable product, combining excellent performance with versatility. This article explores the defining features and applications of 1050 H14 coating aluminum coils, making it an essential read for engineers, manufacturers, and anyone interested in aluminum solutions.

What is 1050 H14 Aluminum?

The designation 1050 H14 aluminum refers to a specific alloy composed predominantly of aluminum (≥99.5% purity) and is categorized under the 1000 series of aluminum. The "H14" temper indicates that the alloy has been cold rolled to enhance its strength. This temper level ensures that while the alloy maintains good ductility, it also has substantial metallic strength, making it ideal for various applications where durability may be key.

Features of 1050 H14 Coating Aluminum Coil

-

Corrosion Resistance One of the most coveted features of 1050 H14 coating aluminum coils is their impressive resistance to corrosion. The coil is often coated to enhance its longevity, preventing weathering and degradation inevitable in more exposed environments.

-

Lightweight and Strong Aluminum is renowned for its excellent strength-to-weight ratio, making the 1050 H14 coating aluminum coil a preferred choice among manufacturers. This trait not only lightens the load in industrial applications but also saves on shipping and operational costs.

-

Excellent Thermal Conductivity Despite being lightweight, the alloy boasts impressive thermal properties, making it suitable for heat exchangers and insulation applications.

-

Versatile Mill Finish Delivery in a mill finish allows for highly aesthetic implementations. It can be easily coated, painted, or otherwise treated to accommodate aesthetically pleasing finishes for diverse applications.

-

Ease of Fabrication The 1050 H14 coating aluminum coil is easy to work with, promoting flawless fabricating processes and tight tolerances, allowing manufacturers to achieve the required specifications without significant waste.

Applications of 1050 H14 Coating Aluminum Coils

-

Building and Construction 1050 H14 aluminum coils are widely used in the construction sector for roofing and siding materials. The corrosion resistance of the coated coils allows for urban building applications where exposure to the elements is a concern.

-

Electrical Conductivity With excellent thermal and electrical conductivity properties, these aluminum coils are commonly utilized in electrical wiring and transformer shell applications, catering to the growing need for sustainable energy solutions.

-

Home Appliances Given its aesthetic appeal and surface treatment capabilities, manufacturers use 1050 H14 coating aluminum coils in fabricating home appliances such as refrigerators and air conditioning units.

-

Transportation The automotive and aerospace industries gain from adopting this aluminum alloy due to its lightweight nature, enhancing fuel efficiency in vehicles while ensuring superior performance standards when tackling extreme environments.

-

Industrial Products These coils are also leveraged in producing containers and chemical vessels, where durability and resistance to chemical reactions are essential.

https://www.al-alloy.com/a/1050-h14-coating-aluminium-coil.html