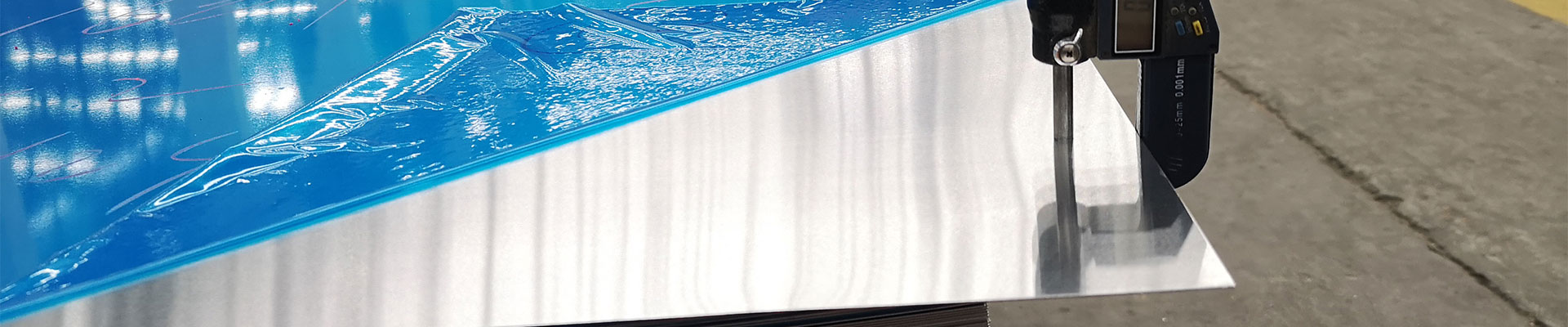

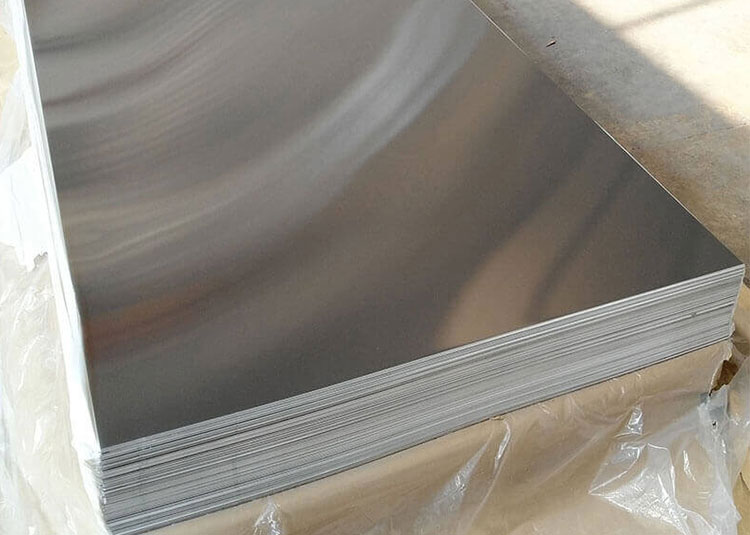

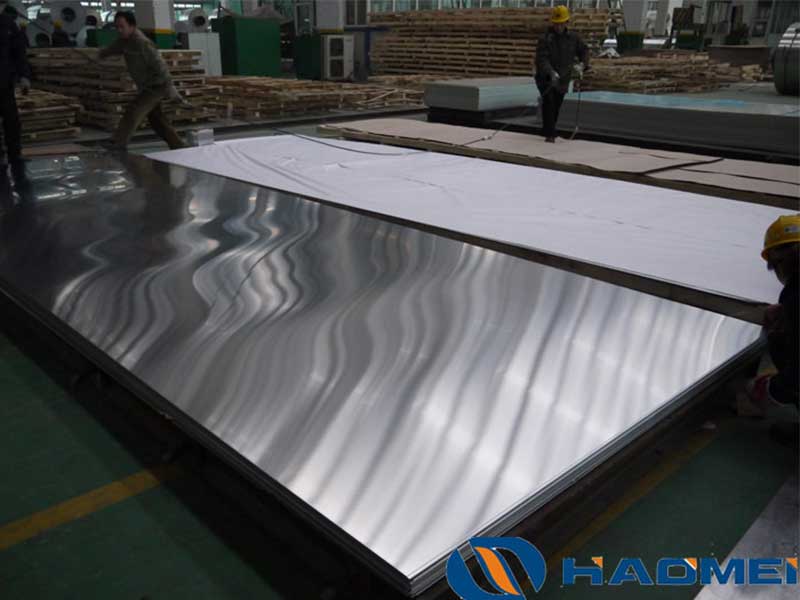

2024 Aluminum sheet is an excellent candidate for most processing techniques. It is a high strength, heat treatable alloy that offers fair corrosion resistance and a high strength to weight ratio. This is a lightweight material with a semi-smooth surface and a dull mill finish. Commonly machined to end user specifications, common applications include aircrafts, marine, motor sports, gears, computer parts, and other commercial grade parts.

Mechanical Performance of 2024 Aluminium sheet with different heat treatments

2024-O

2024-O without heated. Tensile strength 30,000-32,000 psi (207-220 MPa), Yield strength not to exceed 14,000 psi (96 MPa). Elongation 10-12%.

2024-T3

2024-T3, ultimate Tensile strength 58,000-62,000 psi (400-427 MPa), Yield strength 39,000-40,000 psi (269-276 MPa). Elongation 10-15%.

2024-T351

2024-T351, ultimate Tensile strength 68,000 psi (470 MPa), Yield strength 41,000 psi (280 MPa). Elongation 19%.

Typical Applications

2024 alloy, a high-strength hard aluminium, can be heat treated and strengthened, in the quenched and just quenched state plasticity is medium, spot welding good, with gas welding has the tendency to form intergranular cracks, the alloy in the quenching and cold hardening of its machinability is still good after annealing machinability is low, corrosion resistance is not high. It is mainly used for making various high load parts and components (but not including forgings for stamping) such as aircraft skeleton parts, skins, spacers, wing ribs, wing beams, rivets and other working parts below 150°C.