7075 aluminium sheet belongs to Al-Zn-Mg-Cu super duralumin, which is a cold-treated forging alloy with high strength and hardness, far better than soft steel. Due to the fine grain structure inside 7075 aluminium alloy, it has excellent deep drilling performance, enhanced wear resistance of tools, good mechanical properties and anode reaction. At present, 7075 aluminum sheet is the preferred metal material under the requirement of lightweight conditions with lower density and higher hardness.

It is one of the most potential alloys for commercial use. And It is widely used in the manufacturing of shoe mould, high-hardness mould, high-end mobile phone shell, thick plate, heavy forging and golf components, precision parts and aircraft.

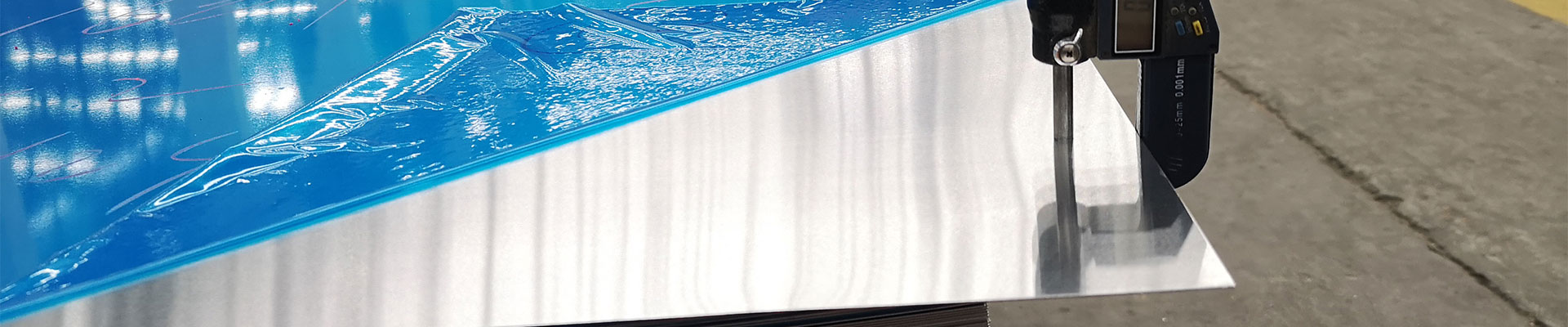

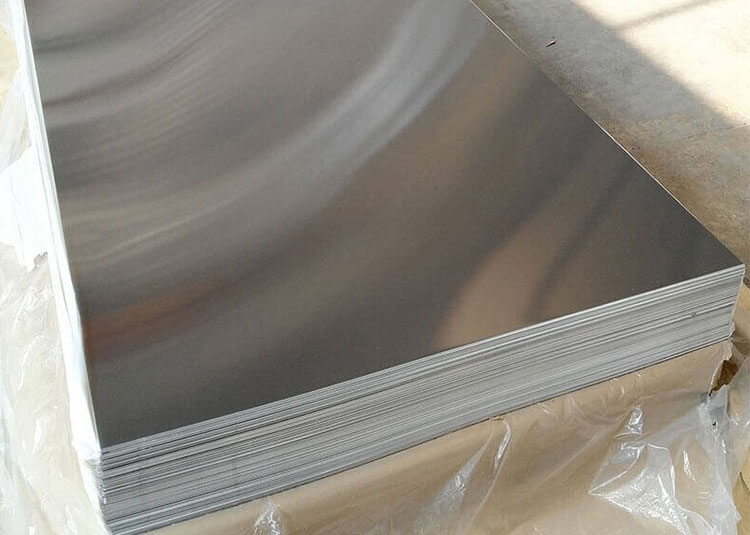

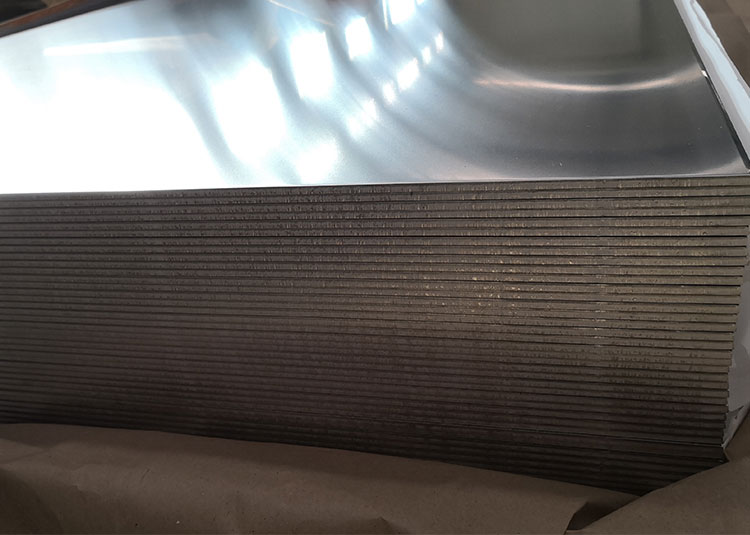

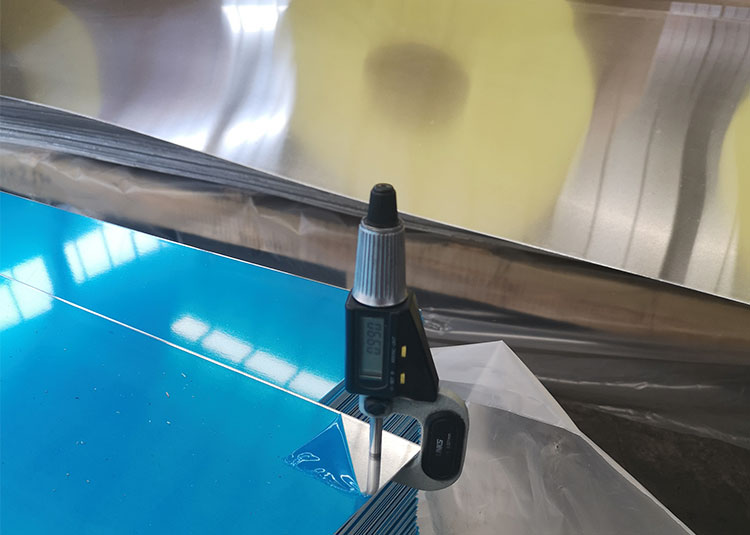

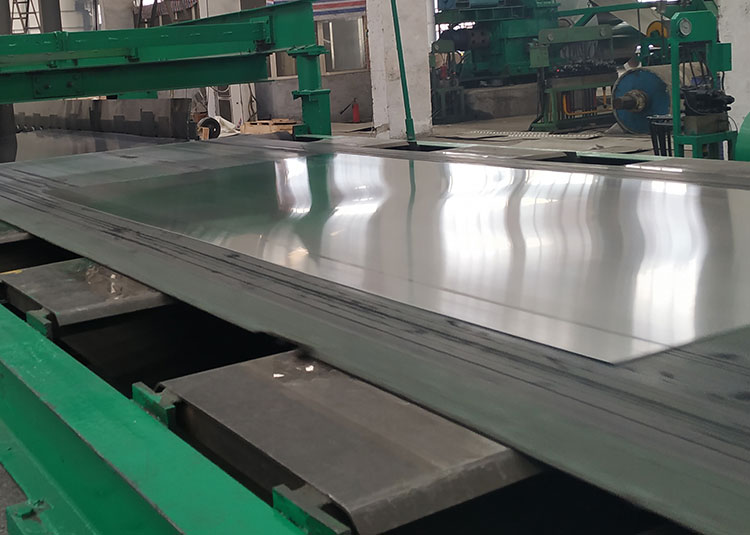

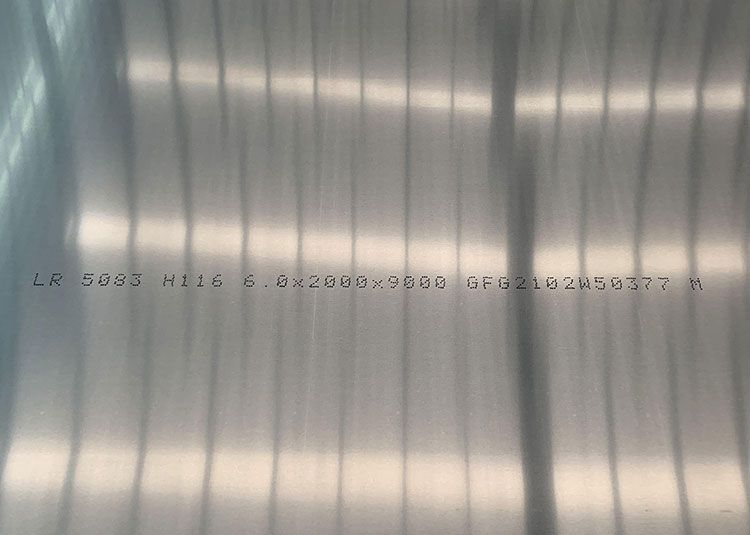

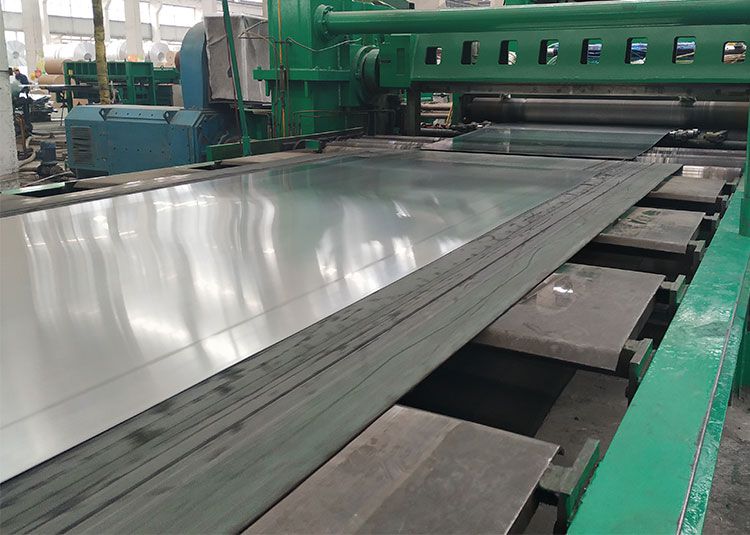

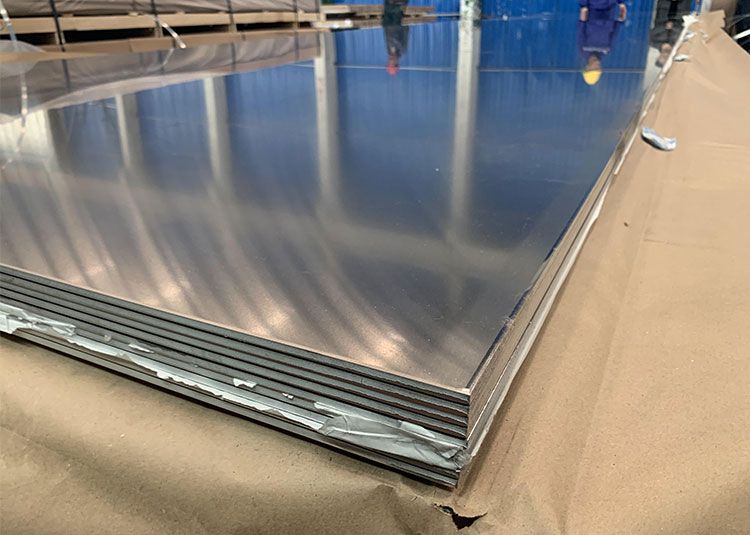

As a professional manufacturer and wholesaler of aluminium sheets, Haomei can provide 7075 aluminum sheet with various specifications, superior quality, competitive price and fast delivery. Haomei has a huge stock of common specifications, as well as the special sizes, can be customized.

Chemical Composition of 7075 Aluminium Sheet

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.20 | 0.05 | 0.15 | Remainder |

| Mg | Fe | Cu | Mn | Si | Cr | Ti | Zn | Others | Al |

| 2.1-2.9 | 0.50 | 1.2-2.0 | 0.30 | 0.40 | 0.18-0.28 | 0.20 | 5.1-6.1 | 0.05 | Remains |

The Features of 7075 Aluminum Sheet

1. High Intensity. 7075 aluminium sheet is stronger than mild steel. After solution treatment, the plasticity is good, with high strength below 150℃ and excellent low-temperature strength.

2. Strong Stress Corrosion. The stress corrosion performance of 7075 aluminum sheet is better than that of 7A04, especially in the temper of 7075-t651.

3. Good Heat Treatment Strengthen in Effect. Zn is the main alloy element in 7075 aluminium sheet. Mg is added to the alloy containing 3%-7.5% Zn so that the heat treatment strengthening effect of 7075 aluminium alloy is far better than that of Al-Zn binary alloy.

4. Other features. The plasticity under annealing and hardening conditions is slightly lower than 2A12 in the same state but slightly better than 7A04, etc.