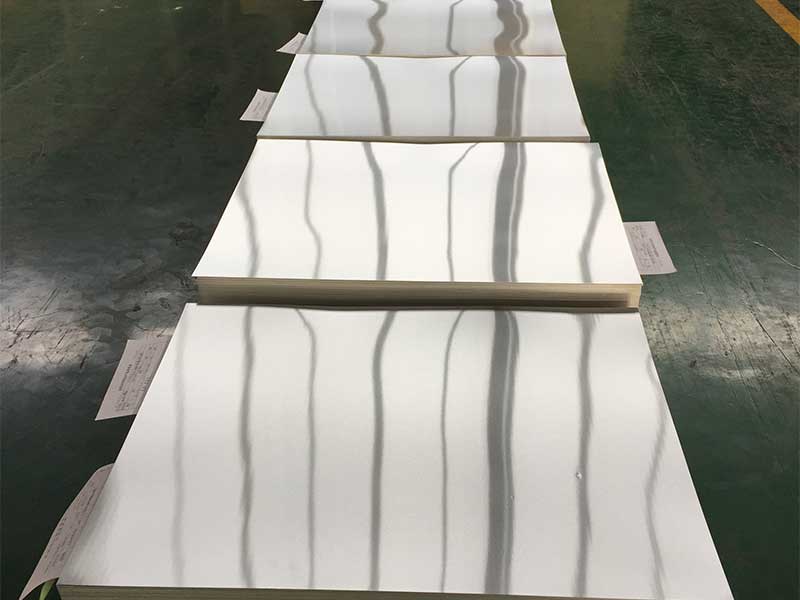

1100 aluminum sheet metal

In the world of metal fabrication, 1100 aluminum sheet metal emerges as a standout performer, offering a unique combination of physical characteristics and functional capabilities. Requiring a deeper of this marvel often leads us down a path filled with technical intricacies and diverse applications that benefit numerous industries.

What is 1100 Aluminum?

In the 1000 series of aluminum, 1100 aluminum sheet metal consists of a minimum of 99.0% aluminum content, providing it with exceptional malleability and high corrosion resistance. Known for its excellent workability and thermal properties, 1100 aluminum also displays significant formability as it can easily be drawn or rolled into sheets without a loss in material integrity.

1100 aluminum sheet is a workhorse in our factory, prized for its excellent formability and corrosion resistance. We see it used extensively in applications requiring deep drawing, spinning, or bending, where its softness and ductility are crucial. Its pure aluminum composition (99% minimum) makes it relatively easy to weld and machine, though it's not as strong as some of the alloyed sheets we process. A common challenge is managing its susceptibility to scratching and marring during handling and fabrication; careful attention to tooling and surface protection is vital to maintain product quality. We often encounter situations where customers request specific surface finishes, demanding extra care in our processes to meet those exacting standards.

One insightful observation from years of working with 1100 aluminum sheet is the importance of considering its annealing state. The material's properties, particularly its strength and work-hardening rate, change significantly depending on its thermal history. A poorly annealed sheet can crack during forming, while an over-annealed one might be too soft for the intended application. We've learned to meticulously track and control the annealing process to ensure consistent performance, relying heavily on precise temperature monitoring and careful cooling techniques to guarantee the final product meets customer specifications and avoids costly rework or scrap. This attention to detail is particularly critical when dealing with larger orders and complex geometries.

Technical Specifications

- Chemical Composition: Primarily made up of aluminum, the alloy elements include silicon, iron, copper, manganese, magnesium, chromium, zinc, and titanium in negligible amounts. The dominant presence of aluminum chapters its preference in terms of purity and functional employs.

- Temper Designations: Commonly produced in what is referred to as the 'H14' temper, which specifically denotes a sheet that has been strain-hardened and provides ideal conductive and chemical performance suited for specific functions, including but not limited to heat exchangers and chemical processing.

- Mechanical Properties:

- Tensile Strength: Approximately 110-135 MPa, making 1100 aluminum relatively low in strength compared to other aluminum grades but sufficiently adequate considering its excellent ductility.

- Elongation: At around 45%, this property indicates its ability to stretch or deform under pressure, another reason behind its extensive applications across specialized industries.

- Thermal Conductivity: Exceptional warmth transfer characteristics make the 1100-grade sheet a first-choice material in thermal applications.

Functions and Applications

Culinary Uses

One of the most recognizable applications for 1100 aluminum sheet metal lies in the culinary domain. Known for its non-toxic nature, it's widely used in kitchen utensils, cooking equipment, and food processing units. Even aluminum foil used in homes maintains quality imports from its raw 1100 aluminum framework.

Electrical

What makes 1100 aluminum indispensable in electrical applications is its superior conductivity. Electrode panels found in generators, heat exchangers, and electrical hardware maintain lesser energy loss while exhibiting unmatched functionality. These properties resonate especially in industries that deal with high-capacity electrical transmissions and installations, enhancing performance criteria significantly.

Chemical Processing Industries

In environments handling corrosive substances, the high corrosion-resistant nature of 1100 aluminum sheets indicates their practicality in storing chemicals and for constructing tanks, vessels, and pipelines. Their sturdiness and durable characteristics resist a long service life, ensuring manufacturers leverage cost lawsuits against frequent equipment failures.

Architectural Applications

Architects and engineers adore employing 1100 aluminum sheets in architectural panels and roofing systems. SILOS with minimal upkeep shows an excellent blend and stylized appeal. The versatility in design approach allows cutting, bending, and forming with marked accuracy, making each installation reflective of cutting-edge design visions.

Manufacturing

1100 aluminum sheets have made themselves irreplaceable in car manufacturing and aircraft body panels. The substance doesn’t sand or rust easily, ensuring lasting usage while decreasing overall vehicle weight—a fundamental requirement of modern automobile designs for better fuel efficiency.

Art and Aesthetics

Crossing into the realm of artistic expression, 1100 aluminum sheet metal finds conversion into detailed sculptures and high-quality signage. The metal’s gleam oscillates across surfaces, refusing abrasion while retaining the dictated forms—the torch-wielding abilities thus become manifestations of imagination and innovation.

Final Thoughts

The epitome of versatility, strength characterized by ductility and corrosion resistance solidifies 1100 aluminum sheet metallization essential across diverse applications. From energy amplifier bathrooms, design-defined infrastructure, culinary creations, to artsy visuals, its stature cannot be confined. As industries progress into greener infrastructures or curated designs, the answer stays synonymous with perfectly compounded forms--where durability, style and environmental compatibility seamlessly connect.

and adopting 1100 aluminum is beneficial to all businesses harping for excellence brought:

- In exchanging out misplaced reliance on less efficient metals

- Gathering industry sustenance$$ helping redesign against needed sustainable progress.

- Prolonging operations effortlessly while gleaming promising designs speaks sundry success tired never-ending endeavors.

As we culminate this of 1100 aluminum sheets and celebrate its multiple facets as valid reasons pushing forward exposed usage, decoding possibilities inspire creativity eyes towards overcoming innovative frameworks paced ahead through enhancement-effort-free integrations heavily valued by markets✓ environments met SO much!!!