Aluminum foil for packaging

In the daily rhythm of our lives, it’s easy to overlook the simple things that make a significant impact. One such unsung hero is aluminum foil—a durable, versatile material that has transformed how we package and consume food. From the leftovers smothered in shiny silver layers to that perfectly wrapped sandwich, aluminum foil plays a pivotal behind-the-scenes role in our culinary experiences.

The Versatility of Aluminum Foil

First, let's celebrate versatility itself. Aluminum foil can adapt to countless culinary scenarios: it's an ultimate wrap for food items, a baking enchantress, and a brilliant barricade against heat and moisture. Its thin metallic skin seems inconspicuous, but it embodies distinct functionalities such as preventing cross-contamination. Rest assured, a loaf of bread shielded from airborne moisture won't become a somber sponge bearing the weight of lost freshness.

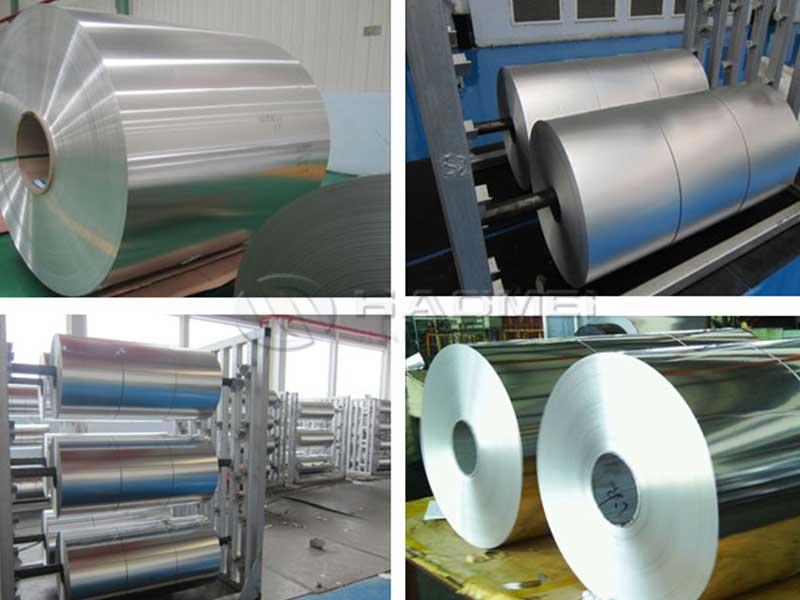

From a production standpoint, the seemingly simple aluminum foil used in packaging presents a surprising array of challenges. Maintaining consistent gauge is crucial; even minor variations can impact the foil's tear resistance, resulting in costly rejects and dissatisfied customers. We've seen firsthand how seemingly insignificant changes in the alloy composition, or even the temperature and speed of the rolling process, can affect the foil's overall strength, its ability to form sharp creases without cracking (important for intricate packaging designs), and its susceptibility to pinholes – a major concern for products requiring airtight seals. Optimizing these factors requires constant monitoring and fine-tuning of our equipment, and often involves collaborative problem-solving with our suppliers to ensure consistent raw material quality.

Beyond the production line, our experience shows that the ultimate performance of the foil in packaging depends heavily on the application itself. A foil designed for wrapping baked goods needs different properties than one intended for aseptic packaging of liquids. For example, a higher barrier against oxygen is paramount for products prone to oxidation, while ease of formability is essential for products requiring intricate shapes. We've learned that close collaboration with our packaging clients is essential to understand their specific needs and provide tailored foil solutions that meet their demands for strength, barrier properties, printability, and overall cost-effectiveness. This tailored approach has led to significant improvements in both product preservation and customer satisfaction.

An Eco-Conscious Comeback

Often shadowed by concerns about environmental impact, it’s crucial to address aluminum foil's sustainability aspect. Mined and processed responsibly, aluminum can boast a 100% recyclability factor. Once a generation’s worth of food is enjoyed, the leftover foil can simply return to the smelting process to be reborn without a loss in quality. Increasingly, manufacturers are moving toward using recycled aluminum in their productions, which significantly minimizes emissions compared to primary aluminum production. Encouraging a fully circular economy, this practice aligns with the growing consumer consciousness toward sustainability—changing minds one meal at a time.

Contributions Clearly Beyond Kitchen Walls

Let’s stretch our perspective beyond the kitchen. In the medical realm, aluminum foil finds a place we rarely consider. Its anti-bacterial properties present commercial applications within the food safety industry. Its barrier against air and light helps pharmacies store sensitive medications that require shielded environments. Moving further, it has even carved a niche in the tech-savvy world. Stanley tools fashion tools for passive components wrapped in aluminum for HVAC systems too—not just confined to food!

Culinary Innovation Fostered by Foil

In culinary innovations, gourmet chefs attuned to modern cooking methods have redesigned how foil is utilized. Think of its role in sous-vide—cooking vacuum-sealed food items in temperature-controlled water baths. Aluminum foil provides the protective wrap ensuring no water leaks in while still allowing even heat distribution. This simple material has opened new avenues for texture and flavor mastery that only a few years back weren’t even imaginable in home kitchens. For the consumers driven by experimentation, tastemakers, and culinary enthusiasts, aluminum foil has become a bridge to exploration of authenticity and creativity.

A Trusty Companion in Our Daily Lives

More than anything, aluminum foil presents itself as a trustworthy companion in our daily lives—a steadfast ally in navigating the balance between convenience and quality. Picture this: a family packing up breakfast burritos for a children’s soccer game, or a busy professional saving half a conference lunch for an overworked dinner—spread out against tempting fast-food chains. Thanks to aluminum foil, these experiences remain efficient, helping reduce waste and preserving each delightful flavor.