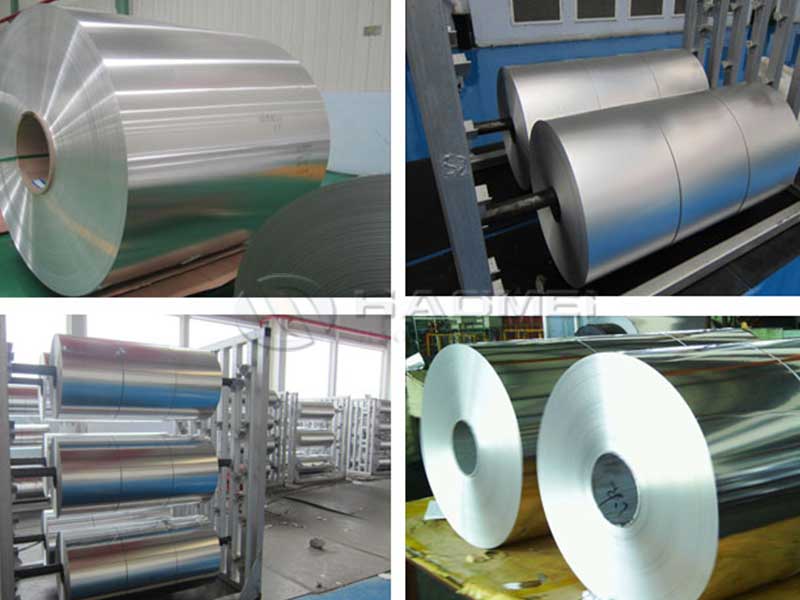

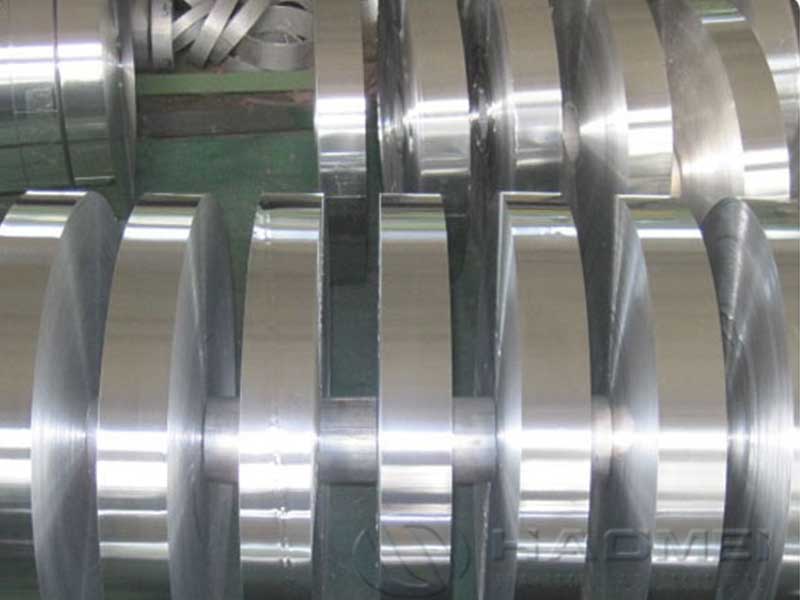

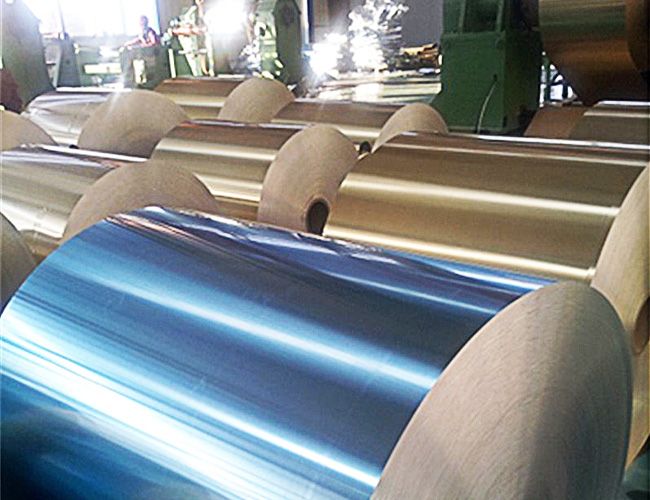

Aluminum foil is produced by rolling aluminum slabs cast from molten aluminum in a rolling mill to the desired thickness less than 0.2 mm . It provides a complete barrier to light,oxygen, moisture and bacteria. For this reason, foil is used extensively in food packaging and pharmaceutical packaging. It is also used to make aseptic packaging that enables storage of perishable goods without refrigeration.

Aluminium Foil’s Amazing Properties:

Cost effective

Barrier to moisture, oxygen and other gases, odours, light, fats and grease

Excellent corrosion resistance

Non-toxic; inert to most foods, drugs and cosmetics

Imparts no detectable taste or odour to foodstuffs

Hygienic: foil is sterilized during annealing and does not harbour or promote bacterial growth

Non absorptive

Withstands a wide range of temperatures from deep freeze to the oven

Excellent thermal properties

Excellent heat conductivity and heat dissipation

Good electrical conductivity

High surface reflectivity

Good burst and tear strength yet lightweight and durable

Excellent formability with dead fold properties

High decorative appeal, excellent surface for printing, coating and laminating

Compatible with other laminating material

Recyclable

ALUMINUM FOIL PACKING PHYSICAL REQUIREMENTS:

1.1 ALLOY AND TEMPER

Alloy | Temper |

1060、1050、1235、1100、 3003、8011、8079 | O、H14、H18、H19、 H22、H24, H26 |

1.2 SPECIFICATION AND TOLERANCE

| Gauge mm | Width mm | Gauge Tolerance % | Width Tolerance mm | ID mm | OD mm | Core Material |

| 0.005-0.2 | 40-1650mm | +/-5% | +/-1 | 76, 152 | 100-950 | Aluminum |

1.3 CHEMICAL COMPOSITION

Here the chemical composition covers alloy 8011 or alloy 1235.

| Alloy | 8011 | ||

Chemical Composition (max %) | Si | 0.50-0.9 | (Si+Fe):0.65 |

| Fe | 0.6-1.0 | ||

| Cu | 0.10 | 0.05 | |

| Mn | 0.20 | 0.05 | |

| Mg | 0.05 | 0.05 | |

| Cr | 0.05 | ------ | |

| Zn | 0.10 | 0.10 | |

| Ti | 0.08 | 0.06 | |

| Others | ------ | V:0.05 | |

| Al | Remainder | ≧99.35 | |

Remark:Foil covered herein is 8011/1235 alloy aluminum master rolls at specified gauges of 0.005-0.050mm nominal thickness.

1.4 MECHANICAL PROPERTIE

Product | Gauge | Alloy-Temper | Mechanical Properties Tensile Strength (Mpa) Elongation(δ%) | |

Aluminum Foil for Pharmaceutical medicine/blister | 0.006-0.009 | 1235-O | 60~80 | ≥1.0 |

>0.009-0.020 | 60~80 | ≥1.0 | ||

>0.020-0.030 | 60~80 | ≥1.0 | ||

0.018-0.030 | 8011-H18 | ≥180 | ≥2.0 | |

0.009-0.08 | 8011-O | ≥75 | ≥3.0 | |

Beer Bottle Wrapping Foil | 0.009-0.010 | 8011-O | 80~105 | ≥2.0 |

>0.010-0.0115 | 80~105 | ≥3.0 | ||

Toothpaste Tube Foil | 0.009-0.011 | 8011-O | ≥70 | ≥2.0 |

| 0.011-0.016 | ≥80 | ≥3.0 | ||

| 0.016-0.03 | ≥80 | ≥3.0 | ||

| Retort Pouch | 0.006-0.009 | 1235-O | 50~85 | ≥1.0 |

| Tetra Pack | 0.006-0.0066 | 1235-O | 55~70 | ≥1.0 |

| Cigarette Foil | 0.006-0.007 | 1235-O | 70~90 | ≥1.0 |

Foil for Laminating with Paper Board | 0.006-0.007 | 1235-O | 50~70 | ≥2.0 |

| Container Foil | 0.030-0.130 | 3003-H24 | 140~190 | ≥6.0 |

| Hot Seal or Lidding Foil | 0.020-0.060 | 8011-O | 70~105 | ≥4.0 |

| Adhesive Tape Foil | 0.0065-0.012 | 1235-O | ≥50 | ≥1.5 |

| 0.010-0.050 | 8011-O | ≥55 | ≥2.0 | |

| Household Aluminum Foil | 0.010-0.050 | 8011-O 1235-O | 80~110 | ≥2.5 |

Power Capacitor Foil | 0.005-0.009 | 1235-O | ≥60 | ≥1.0 |

| Cable Foil | 0.0065-0.050 | 1235-O 1145-O 8011-O | 40~80 | ≥2.0 |

| Fin Stock | 0.08-0.20 | 8011-H24 1100-H26 | 130~160 | ≥5.0 |

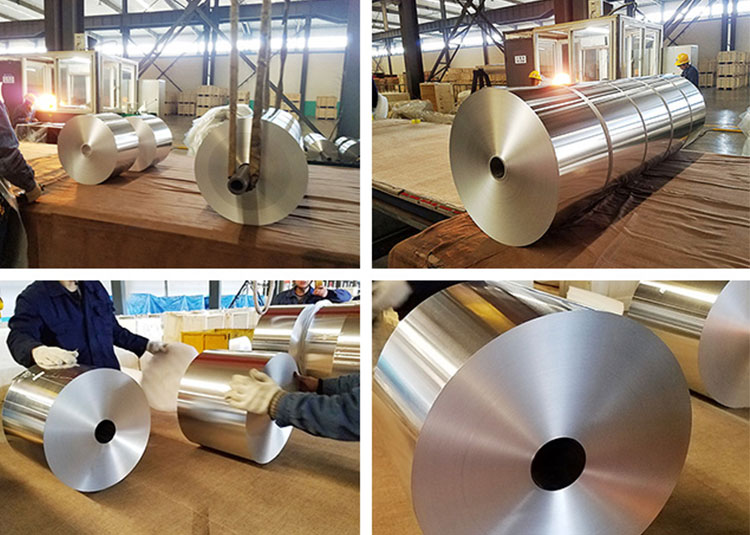

2.PACKING AND SHIPPING REQUIREMENTS

2.1Quantities – As specified on the purchase order with a tolerance of +/- 10% unless otherwise stated on the order.

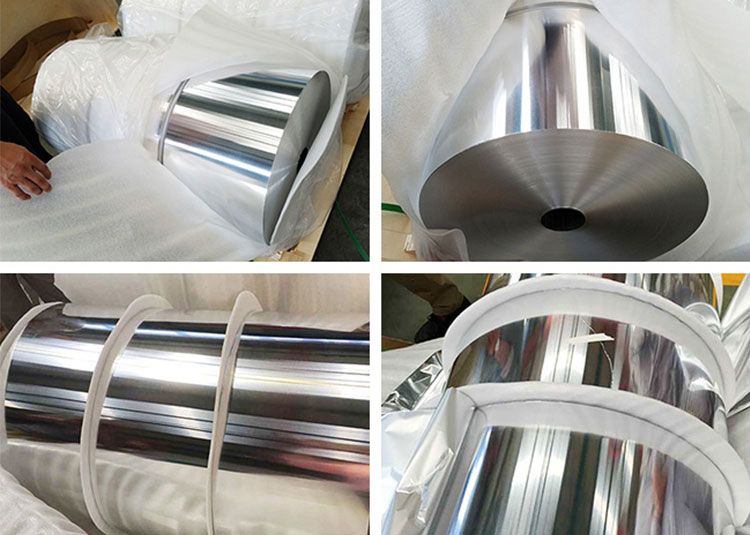

2.2Packaging – Foil rolls are to be packed in standard export wooden box,normal handling by common carrier will ensure safe transportation without damage to the foil. This includes wrapping to protect the foil from water stain and corrosion.

2.3Label – Each roll shall be identified with the following:

a)Product name

b)Alloy/temper

c)Batch number

d)Gauge (mm)

e)Width (mm)

f)Net weight (kg)

g)Gross weight(kg)