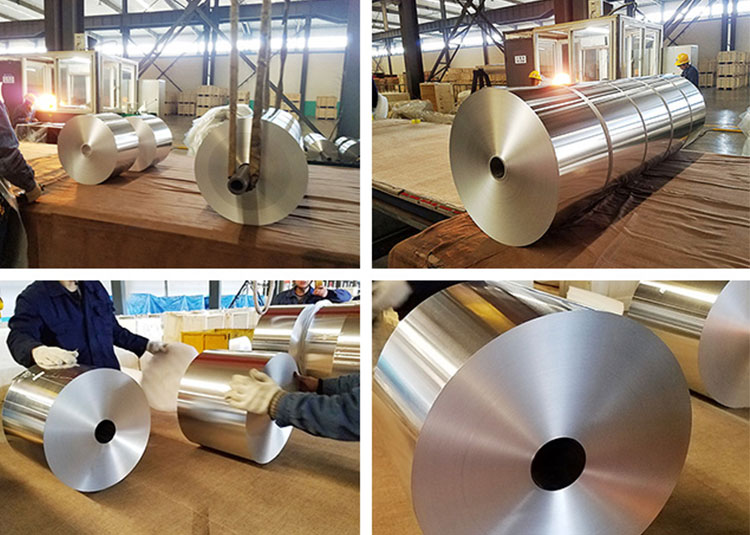

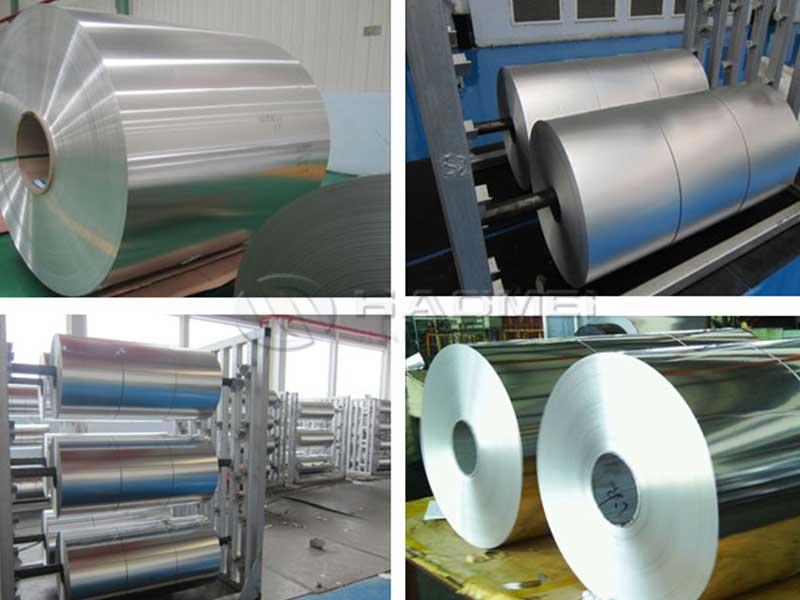

40 Micron 80 Micron Aluminum Foil

Aluminum foil has become an indispensable material across various industries, thanks to its versatility, durability, and exceptional barrier properties. Specifically, 40-micron and 80-micron aluminum foil have distinct characteristics that cater to different applications. In this article, we will explore the differences, benefits, and applications of these two thicknesses, helping you make informed decisions for your packaging and cooking needs.

What is Micron Thickness?

Micron (µm) is a unit of measurement used to quantify the thickness of materials. In the case of aluminum foil, a micron thickness indicates the gauge of the foil, directly impacting its strength, flexibility, and usage. Thinner foils, such as the 40-micron aluminum foil, are suitable for lightweight applications, whereas thicker options like 80-micron aluminum foil are preferred for more robust needs.

40 Micron Aluminum Foil: Lightweight and Versatile

Characteristics

The 40-micron aluminum foil is ideal for lightweight applications due to its thinner profile. Typically, it offers excellent malleability and can easily conform to various shapes, making it perfect for culinary purposes, insulation, and more.

Benefits

- Cost-Effective: Due to its thinness, 40-micron foil tends to be more economical. It’s perfect for use in large batches without straining your budget.

- Easy Handling: The lightweight nature makes it simple to handle and manipulate, ideal for wrapping food items or lining trays.

- Good Barrier Properties: It still maintains decent sealing and barrier properties against moisture, light, and air, which is crucial for food preservation.

Applications

- Culinary Use: Cooking, baking, and food storage. Ideal for wrapping sandwiches or covering dishes.

- Insulation: Can be used in thermal insulation for buildings when combined with other materials.

- Crafting: The malleable nature allows for creative uses in arts and crafts.

80 Micron Aluminum Foil: Robust and Reliable

Characteristics

On the other hand, 80-micron aluminum foil is thicker and more robust. This additional thickness translates into greater strength and durability, making it suitable for more demanding applications.

Benefits

- Enhanced Strength: The thicker material can handle more demanding uses without tearing, making it suitable for heavy-duty applications.

- Superior Barrier Properties: It offers enhanced protection against environmental factors, making it ideal for preserving food and preventing contamination.

- Versatility in Applications: Suitable for a broader range of uses, from industrial packaging to high-temperature cooking.

Applications

- Food Packaging: Perfect for packaging products that require longer shelf life, such as snacks, ready-to-eat meals, and frozen goods.

- Industrial Use: Its strength makes it an optimal choice for insulation, electric and mechanical components, and construction needs.

- Full-Spectrum Cooking: Excellent for grilling, baking, and roasting where higher durability is required.

Choosing Between 40 Micron and 80 Micron Aluminum Foil

When deciding between 40-micron and 80-micron aluminum foil, consider the specific needs of your project or application. If your primary focus is on lightweight tasks or cost-efficiency, the 40-micron foil may be your best bet. However, for tasks that demand extra protection and durability, the 80-micron option would be more suitable.

Sustainability Considerations

Both thicknesses of aluminum foil can contribute to sustainable practices. Aluminum is fully recyclable, which significantly reduces its environmental footprint. By opting for high-quality aluminum products, you ensure greater efficiency and longevity, promoting a more sustainable operational approach.

https://www.al-alloy.com/a/40-micron-80-micron-aluminum-foil.html