Aluminum foil for duct

In the world of heating, ventilation, and air conditioning (HVAC), various materials are utilized to ensure seamless temperatures and optimum air flow. Among these materials, aluminum foil has asserted itself as a significant player in ductwork applications, unmatched in efficiency, durability, and thermal optimization.

What is Aluminum Foil Ducting?

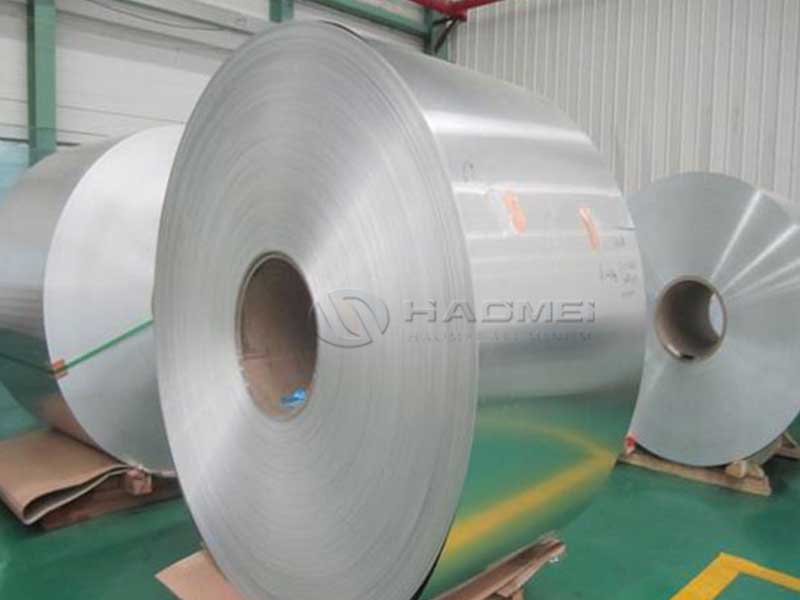

Aluminum foil ducting refers to duct systems made primarily of thin sheets of aluminum coated with a layer of foil. Specifically designed to facilitate the efficient movement of air within a building, these ducts are ideal for various HVAC applications, including air conditioning, ventilation, and heating. Known for their lightweight nature and seamless capabilities, aluminum foil ducts typically consist of a robust stainless steel outer layer, lined with highly effective foam insulation.

Okay, so I've been with Aluminite Foil for fifteen years now, and let me tell you, I've seen a lot of aluminum foil go through this place – from the ultra-thin stuff used in food packaging to the thicker gauge we use in industrial applications. Duct work is definitely a niche area, and I have some strong opinions, formed by both the science and the shop floor realities:

The Good:

Outstanding Features of Aluminum Foil Ducting

1. Excellent Thermal Conductivity

Aluminum is known for its superior thermal properties. It experiences minimal thermal transfer—meaning it retains conditioned air longer, optimizing energy usage. This minimizes the need for HVAC systems to work overtime to maintain desired temperatures, contributing to lower utility bills and enhanced comfort.

2. Corrosion Resistance

The innate characteristics of aluminum foil confer resistance against rust and corrosion. Unlike traditional metal ducts that may succumb to moisture, aluminum foil remains unaffected by water contact, promoting longevity and minimizing structural degradation in humid environments. This quality ensures that the ventilation system remains effective and reduces homeowners' worries over frequent repairs.

3. Flexibility and Lightweight Design

In environments where space is a premium, especially in specifically carved-out attic systems or while concealed under insulation, aluminum foil ducts have the advantage of being lighter and more malleable than other duct materials. The flexibility of aluminum allows for easy handling, modifications, or bends when shaping straight ducts. It simplifies installation, reduces labor costs, and increases versatility concerning personal or design needs in any HVAC setup.

4. Cost-Effectiveness

As homeowners become increasingly interested in energy efficiency solutions, purchasing cheaper, higher maintenance alternatives with worse insulation unfolds additional costs while potentially putting comfort at risk. It is cost-effective in both choice of material and operational efficiency. Aluminum ductwork typically comes with a one-time installation cost and excel compensating energy bills over time.

5. Eco-Friendly

Aluminum is 100% recyclable without any loss of purity. This inherent property allows aluminum vapor to join the "green" building spirit; it represents responsible ecological practices while demonstrating high performance in HVAC applications. With growing emphasis on sustainable construction and products, the aluminum foil duct is at the forefront of these innovations in the construction and energy sectors.

Applications in Various Settings

Aluminum foil ducting finds application across multiple domains, including:

-

Residential Homes: Ideal in conventional home settings thanks to efficient local heating and seamless installation, they ensure airflow targeting vital spaces to maintain consistent comfort.

-

Commercial Spaces: In large-scale designs, this ducting's capacity expansions prove useful. Its lightweight attribute and reduced bend restrictions perfectly fit it to intricate designs integral to modern architecture.

-

Industrial Applications: High-density working environments, such as laundries and factories, entrust aluminum foil to maneuver heated air to specific hot areas, adding customization based on individual needs while preventing air contamination from surrounding workspaces.