TECHNICAL SPECIFICATIONS

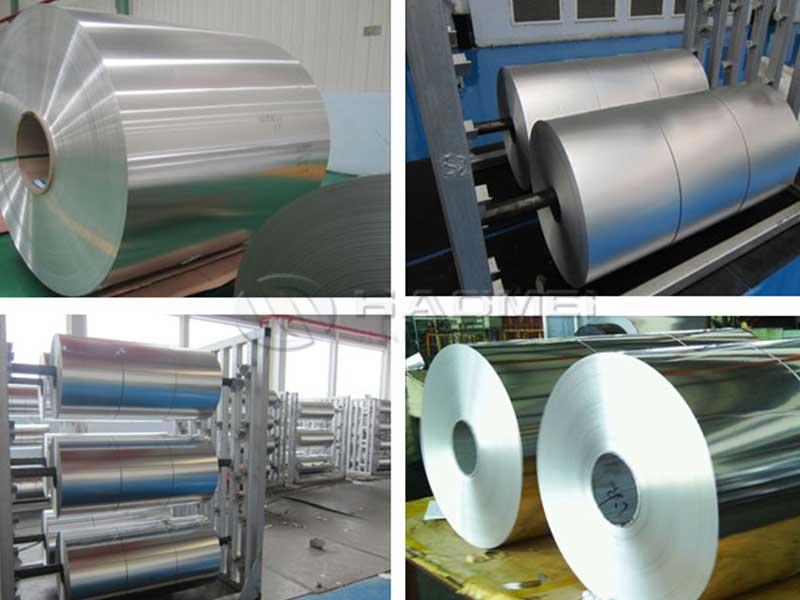

Thickness: 0.009-0.03mm

Width: 250-1280mm

Material (alloy): 8011

Aluminm is lighter in weight and more cost effective than copper.

Thicker film substrates provide higher dielectric and tensile strength.

Thicker foil substrates provide higher conductivity and tensile strength, and lower signal attenuation.

Tips: product width size is divided according to customers’ needs.

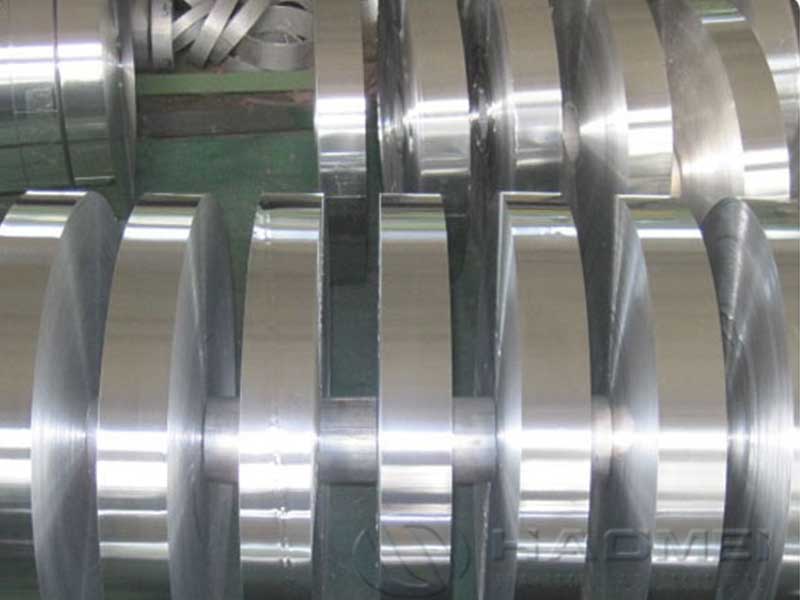

| Alloy | Temper | Thickness(mm) | Width(mm) | I.D.(mm) | O.D.(mm) | Thickness Tolerance(%) | Length | Lightness |

| 1050 | O | 0.01-0.3 | 300 | 76 | 500 | ≤5 | COIL | ≤60 |

| 1060 | O | 0.01-0.3 | 300 | 76 | 500 | ≤5 | COIL | ≤60 |

| 8011 | O | 0.01-0.3 | 300 | 76 | 500 | ≤5 | COIL | ≤60 |

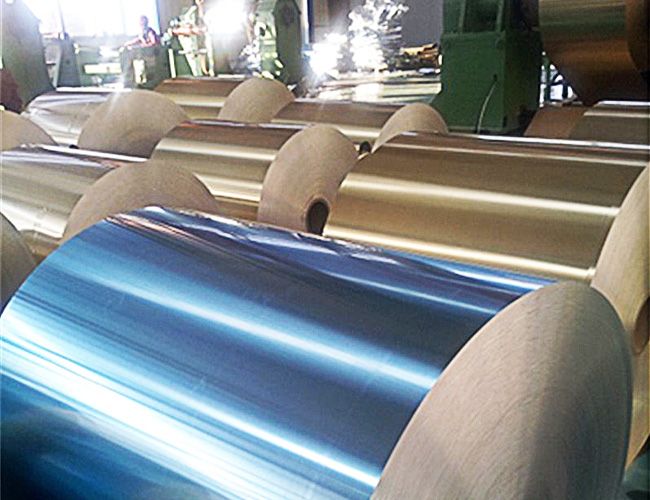

CABLE ALUMINUM FOIL APPLICATION:

Mainly used in construction ,decoration ,packing ,printing, cover material ,piping, electronic, elements, refrigeration, air condition, automobile ,etc.

We possess advanced composite machine and cutting mchine, we can cut aluminun foil mylar to the width of 5mm to 1.5m. The main composite materials are PE, PET, BOPP etc.