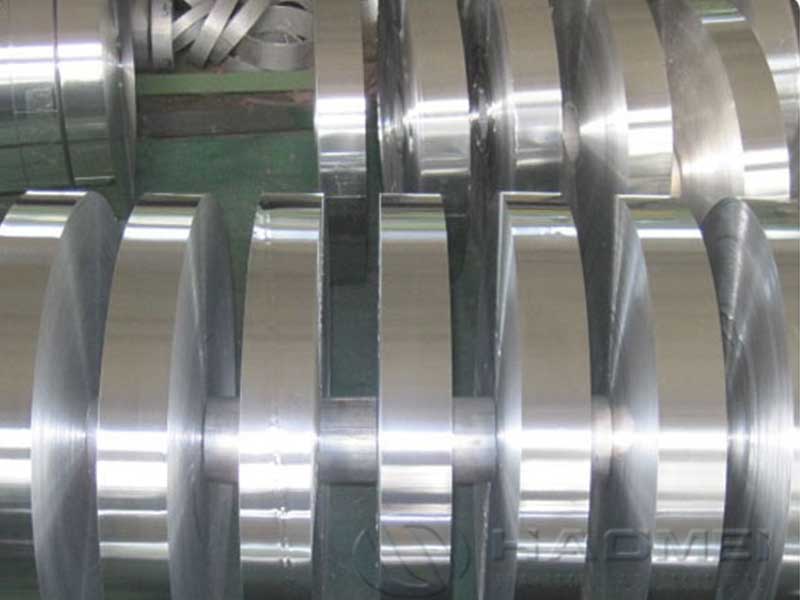

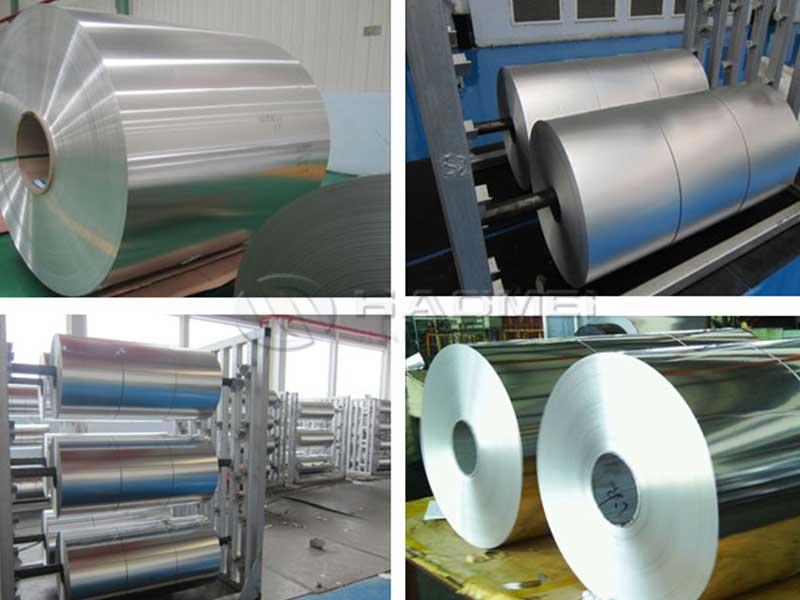

3003 5052 8011 8021 aluminum foil for packaging

When it comes to packaging materials, aluminum foil enjoys a robust reputation for its outstanding protective properties, recyclability, and versatility. Among the various grades available, 3003, 5052, 8011, and 8021 is know due to their unique features and broad applications. Let's delve deeper into each of these alloys and uncover why they are favored in the packaging industry.

1. 3003 Aluminum Foil: Lightweight and Excellent Formability

The 3003 alloy is renowned for its lightweight properties and excellent workability, thanks to its high manganese content. This foil displays remarkable corrosion resistance, making it ideal for a variety of applications. It also possesses good elongation, rendering it easy to shape and manipulate into different sizes without tearing or breaking.

Applications: 3003 aluminum foil is highly utilized in food packaging, particularly for containers and lids in the food service industry. Its ability to retain temperature makes it great for use in hot food storage and transport. Additionally, it finds utility in decorative applications and insulation due to its lightweight attributes.

2. 5052 Aluminum Foil: Robust and Durable

Boasting a higher resistance to corrosion compared to 3003, the 5052 aluminum foil incorporates a significant dose of magnesium, amplifying its strength and resilience. With improved elongation and good weldability, the 5052 alloy can endure more demanding environments, which makes it suitable for various high-stress applications.

Applications: This alloy's superior attributes are particularly harnessed in the marine and automotive packaging sectors. For instance, in the production of fuel fillers and tanks, where resistance to saltwater and similar corrosive environments is crucial. Additionally, 5052 foil can be used in packaging electronic components and goods that require enhanced protection during shipping and storage.

3. 8011 Aluminum Foil: Excellent Barrier Properties

Recognized for its outstanding barrier properties, the 8011 aluminum foil provides excellent shielding against moisture, light, and gases. This characteristic is pivotal for extending the shelf life of rolled goods, making this alloy an ultimate choice for diverse packaging applications.

Applications: 8011 foil is predominantly used in food packaging, specifically for snack foods, chocolate, and ready-to-cook items due to its high impermeability. It's also favored in pharmaceutical packaging, where it safeguards medications from environmental factors. Notably, because this alloy is made thicker than some options, it's also excellent for electrical materials.

4. 8021 Aluminum Foil: Versatile and Reliable

Closely related to the 8011 alloy, the 8021 aluminum foil is gaining momentum due to its reliability and versatility. Like 8011, it is a non-aluminum alloy and exhibits robust mechanical characteristics and excellent barrier functionality. The composition is often intended for specialized applications, guaranteeing a marking of quality and assurance for future applications.

Applications: 8021 is widely used in advanced food packaging applications such as retort pouches, flexible packaging, and food covers designed for high-temperature settings. It’s also noticed in pharmaceutical packs and sensitive stuff necessitating enhanced security and breakdown data on packaging risks from the biological/disease containment spectrum.

https://www.al-alloy.com/a/3003-5052-8011-8021-aluminum-foil-for-packaging.html