8011 jumbo Aluminum foil rolls

In a world that values both efficiency and versatility, 8011 jumbo aluminum foil rolls have emerged as unsung heroes across multiple industries. Far beyond mere support for culinary endeavors, this high-quality aluminum foil serves numerous purposes that are both functional and innovative.

The Technical Backbone of 8011 Jumbo Aluminum Foil

Before its broad applications, the technical details of 8011 jumbo aluminum foil is crucial. Aluminum foil is classified by its alloy composition, and 8011 is specifically designed for high-performance applications. Constructed with a thickness range between 16 to 30 microns and can be produced in jumbo rolls of multi-ply formats, this type of foil stands out due to its enhanced ductility, superior barrier properties, and anti-corrosive treatment.

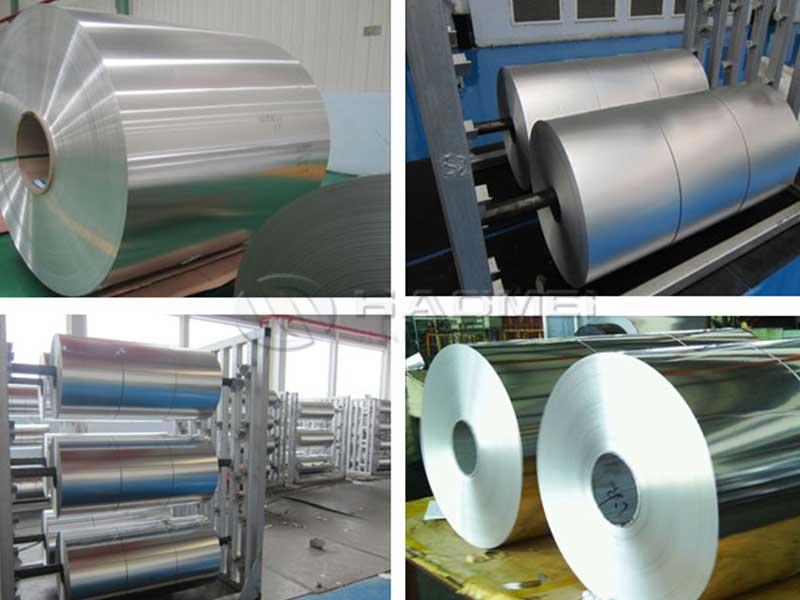

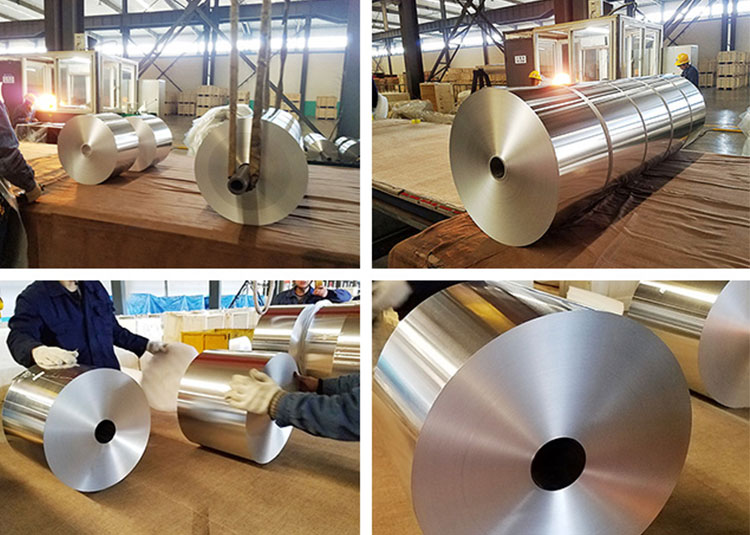

Working with 8011 jumbo rolls of aluminum foil presents a unique set of challenges compared to smaller gauge rolls. The sheer size and weight necessitate specialized handling equipment – from customized forklifts and powered unwind stands to precise tension control systems during the converting process. We've seen numerous instances where improper handling leads to roll damage, including surface scratches, edge crushing, and even tears, significantly impacting yield and potentially necessitating costly rework or scrap. Furthermore, maintaining consistent gauge and surface finish across such massive rolls is critical, requiring meticulous monitoring of the mill's rolling and annealing processes. Slight variations can drastically affect the downstream applications, especially in food packaging where even minor inconsistencies can compromise barrier properties.

One particularly insightful observation is the correlation between storage conditions and roll quality. Improper storage – exposure to moisture, fluctuating temperatures, or even just uneven stacking – can lead to warping, corrosion, and the formation of surface imperfections on these substantial rolls of 8011 foil. This is especially pertinent given the high value of these jumbo rolls and the significant downtime caused by having to replace damaged material mid-production run. Therefore, we've implemented strict procedures for storage and handling, including controlled climate storage areas and regular inspections to proactively mitigate potential problems and ensure the consistent high quality demanded by our customers.

Due to its aluminum content, 8011 foil exhibits excellent thermal conductivity, making it ideal for wrapping and cooking food. This alloy also possesses notable resistance to moisture, gases, and chemicals—factors crucial for maintaining product integrity across industries. Its lightweight nature promotes easy handling without sacrificing strength—a characteristic widely valued in both domestic and industrial environments.

Diverse Functions of 8011 Jumbo Foil

1. Culinary Uses

Initially synonymous with kitchen functions, the culinary benefits of 8011 jumbo aluminum foil are multifaceted. Its ability to withstand standardized ranges of temperature, both cold and hot, offers significant user benefits for packaging cooked foods and leftovers.

From roasting meats to baking vegetables, this foil assists in even cooking and ensures added moisture retention—a technique popular in baking recipes for items like poultry and dishes needing slow cooking. Furthermore, it allows for easy cleanup after food preparation.

2. Food Packaging

Beyond the kitchen, 8011 jumbo aluminum foil rolls shine in the commercial and retail packaging sector. Their innate barrier properties help preserve freshness and taste—far outperforming plastic wraps and polyethylene options.

Food manufacturers and stores employ this foil for wrapping various alimentary products, particularly in chilled or frozen consumables. The foil offers convenience features like zucchini-wrap designs, roll-up packets, and even vacuum packaging.

Moreover, it aids in meeting stringent hygiene and safety standards for foodborne pathogenic concerns, recognizing the growing connection and demand for customer health.

3. Pharmaceutical and Medical Applications

What might come as a surprise is the significant relationship of 8011 aluminum foil in pharma and healthcare sectors. Due to its nonreactive properties, ease of sterility maintenance, and ability to be formed into complex shapes, 8011 foil is used for packaging sensitive medications, blister packs, and sterile wraps.

Pharmaceutical giants build trust with their clientele by utilizing this versatile and effective layering for creating tools that tear open with segmentation—providing safe and efficient access to the medications contained within.

4. Industrial Solutions

In the manufacturing world, heat management is critical. Frame materials offer heat-shielding solutions through wraps and foils, necessitating humble yet properly supported resources. Engineers and integrators utilize 8011 jumbo aluminum foil for electrical and thermal insulation for such operations.

Various electrocooking systems incorporate aluminum foil gaskets into their designs. Whether used in thermal barrier contexts, wiring insulation, or HVAC systems due to its lightweight count and anti-corrosive qualities—the alloy proves indispensable.

Sustainability and Responsiveness

Lastly, covering 8011 jumbo aluminum foil will be incomplete without mentioning its eco-friendly aspect; it is remarkably recyclable. Efficiently shedding down the extra weight for shipping, less energy is used in recycling processes compared to those required for the manufacture of new aluminum products, paving the way for numerous end-life ornamental products and actionable industrial tools as upcycling carries its weight in sustainable practices.

https://www.al-alloy.com/a/8011-jumbo-aluminum-foil-rolls.html